Coke oven burner grouting material and manufacturing method thereof

A technology of grouting material and furnace head, which is applied in the field of grouting material and its manufacture. It can solve the problems of solvent volatilization at high temperature, easy hardening and cracking, and poor fluidity, so as to reduce the smoke and fugitive emission of the furnace head and improve the degree of sealing. , Improve the effect of coke oven environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

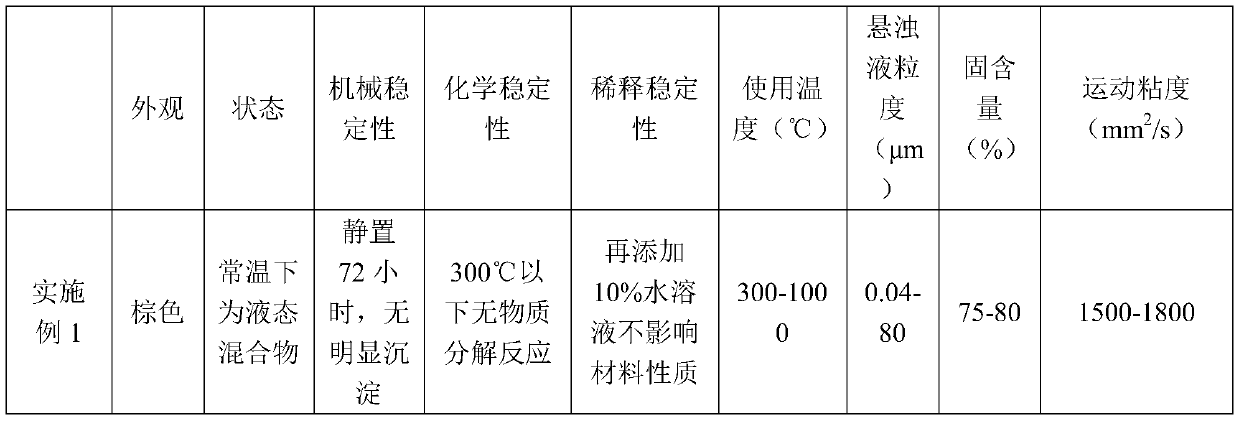

Examples

Embodiment 1-6

[0069] The coke oven head grouting material of embodiment 1-6 adopts following steps to manufacture:

[0070] Adding the silane coupling agent and polydimethylsiloxane to the liquid phenolic resin according to the ratio of the formula to obtain a liquid phenolic resin mixture;

[0071] Mix silica powder, mullite powder and clay refractory mud evenly according to the formula ratio to prepare filler;

[0072] Slowly pour the mixed filler into the liquid phenolic resin mixture during the stirring process, and stir evenly to obtain the coke oven burner grouting material.

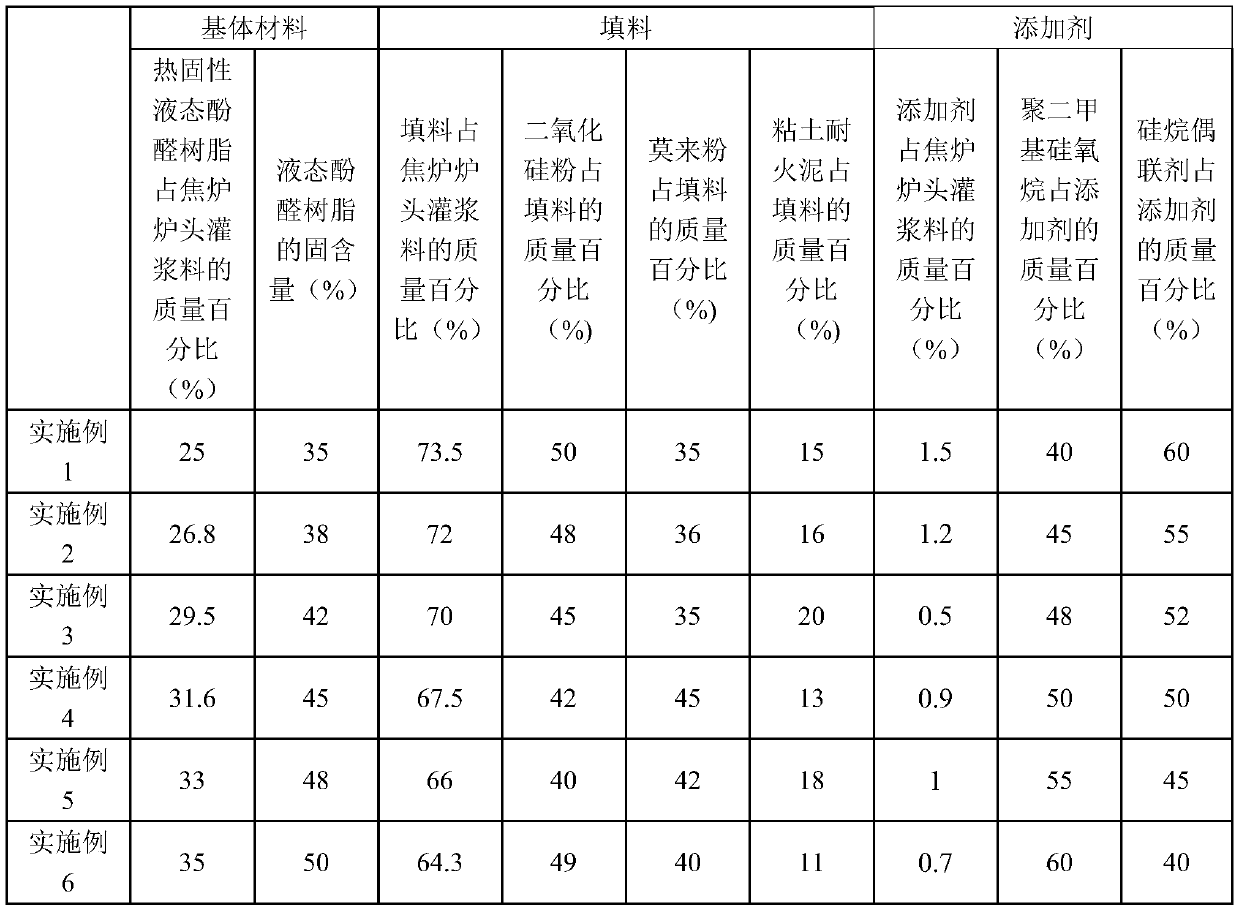

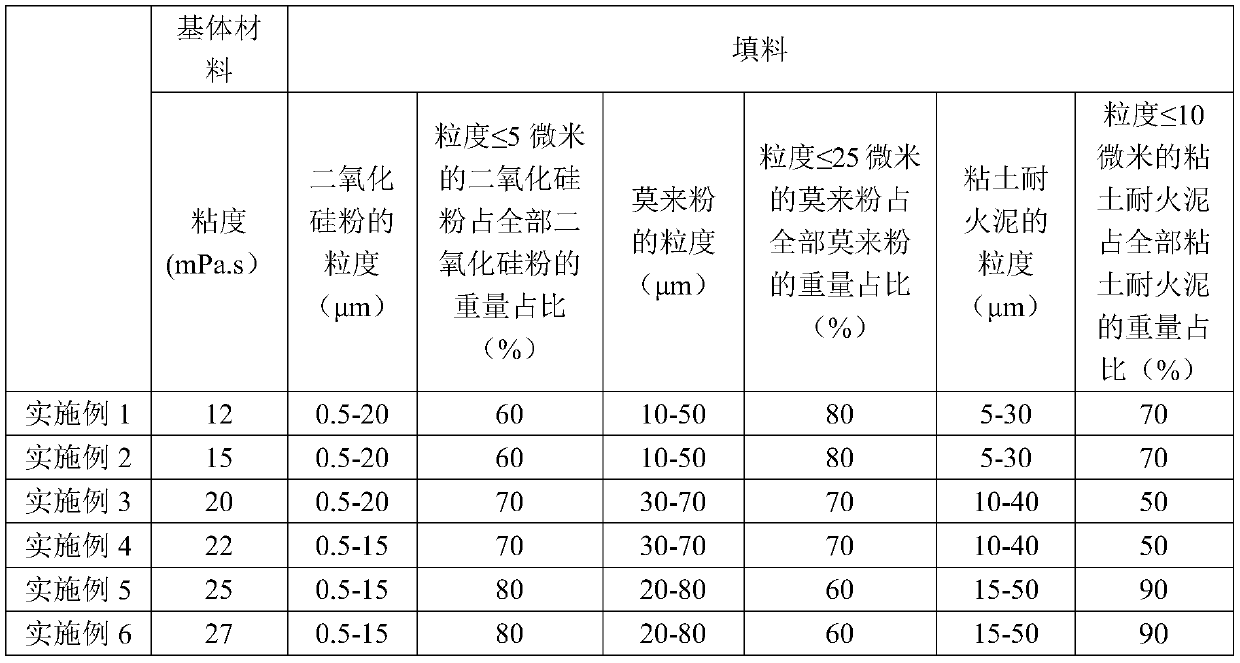

[0073] Wherein, in the coke oven head grouting material of embodiment 1-6, each component mass percent distribution ratio is:

[0074] Thermosetting liquid phenolic resin as matrix material: 25-35%;

[0075] Silica, mullite and clay refractory mortar as filler: 64-74%;

[0076] Silane coupling agent and polydimethylsiloxane as additives: 0.5-1.5%.

[0077] In addition, in the filler, the mass percentage rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com