Super retarding concrete

A concrete and ultra-retarding technology, which is applied in the field of building materials, can solve the problems of super-concrete research difficulties, etc., and achieve the effects of facilitating hydration reaction, improving mechanical strength and durability, and improving rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

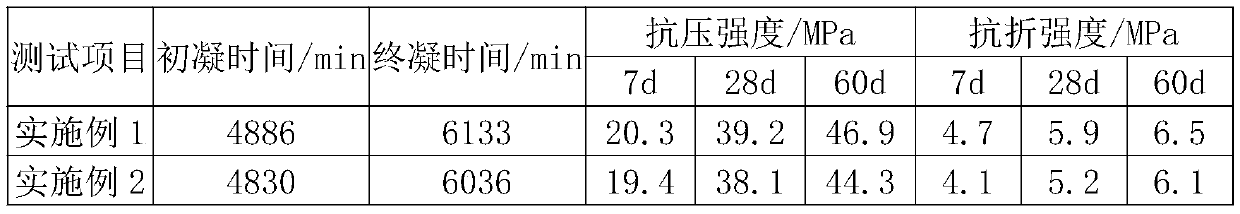

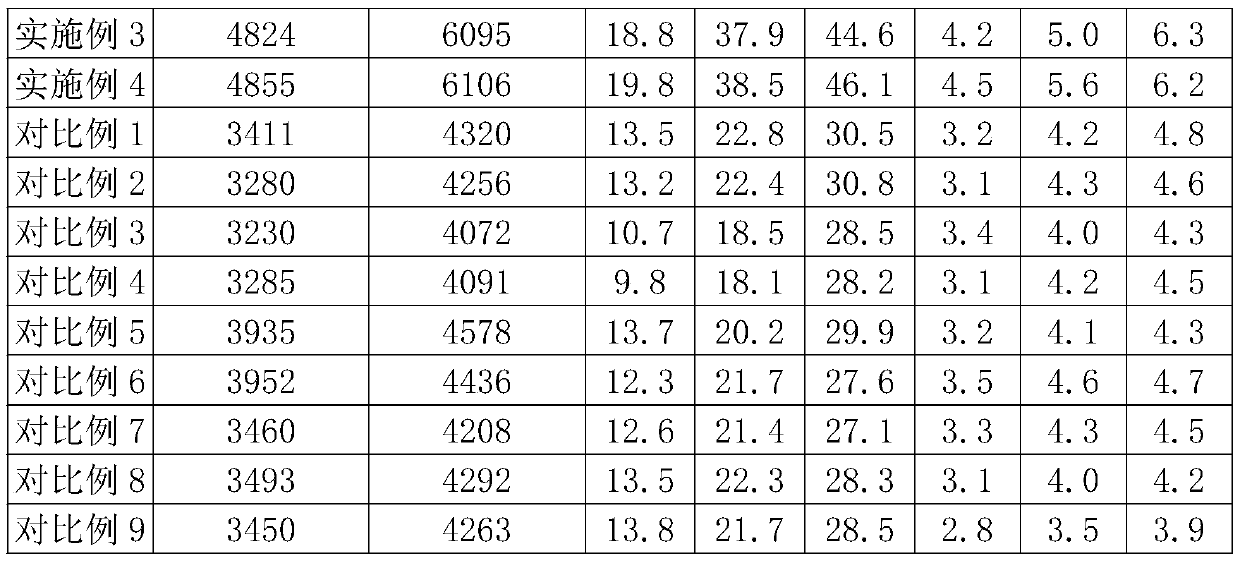

Examples

Embodiment 1

[0025] In this embodiment, an ultra-retarded concrete includes the following raw materials in parts by weight: 210 parts of cement, 30 parts of admixtures, 3 parts of basalt fiber, 8 parts of admixtures, 805 parts of river sand, 985 parts of stones, and water 165 parts, the additive is composed of water reducer, retarder, water retention agent and defoamer, and the weight ratio of water reducer, retarder, water retention agent and defoamer is 6:7:3: 1. The admixture is composed of phosphorus slag, fly ash and microbeads, and the weight ratio of the phosphorus slag, fly ash and hollow glass microbeads is 10:40:10.

[0026] Preferably, the cement is ordinary Portland cement, and the cement strength grade is 42.5.

[0027] Preferably, the basalt fiber has a density of 2.8-3.3 g / cm3, a fiber length of 3-6 mm, a fiber diameter of 15-16 μm, a tensile strength of 3500-4500 MPa, and a tensile modulus of 85-95 GPa.

[0028] Preferably, the river sand is natural river sand, the apparent densi...

Embodiment 2

[0036] In this embodiment, a super retarded concrete includes the following raw materials in parts by weight: 250 parts of cement, 50 parts of admixtures, 5 parts of basalt fiber, 10 parts of admixtures, 810 parts of river sand, 1010 parts of stones and water 170 parts, the additive is composed of water reducer, retarder, water retention agent and defoamer, the weight ratio of water reducer, retarder, water retention agent and defoamer is 8:9:5: 2. The admixture is composed of phosphorus slag, fly ash and microbeads, and the weight ratio of the phosphorus slag, fly ash and hollow glass microbeads is 20:50:15.

[0037] Preferably, the retarder is composed of citric acid and sodium gluconate, and the weight ratio of the citric acid and sodium gluconate is 3:5.

Embodiment 3

[0039] In this embodiment, an ultra-retarded concrete includes the following raw materials in parts by weight: 220 parts by weight of cement, 40 parts by admixture, 4 parts by basalt fiber, 9 parts by admixture, 808 parts by river sand, 990 parts by stone and water 168 parts, the additive is composed of a water reducer, a retarder, a water retaining agent and a defoaming agent, and the weight ratio of the water reducing agent, a retarder, a water retaining agent and a defoaming agent is 7:8:4: 1.5. The admixture is composed of phosphorus slag, fly ash and microbeads, and the weight ratio of the phosphorus slag, fly ash and hollow glass microbeads is 15:45:12.

[0040] Preferably, the retarder is composed of citric acid and sodium gluconate, and the weight ratio of the citric acid and sodium gluconate is 2:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com