Hydroxy acrylic resin material composition and its preparation method and application

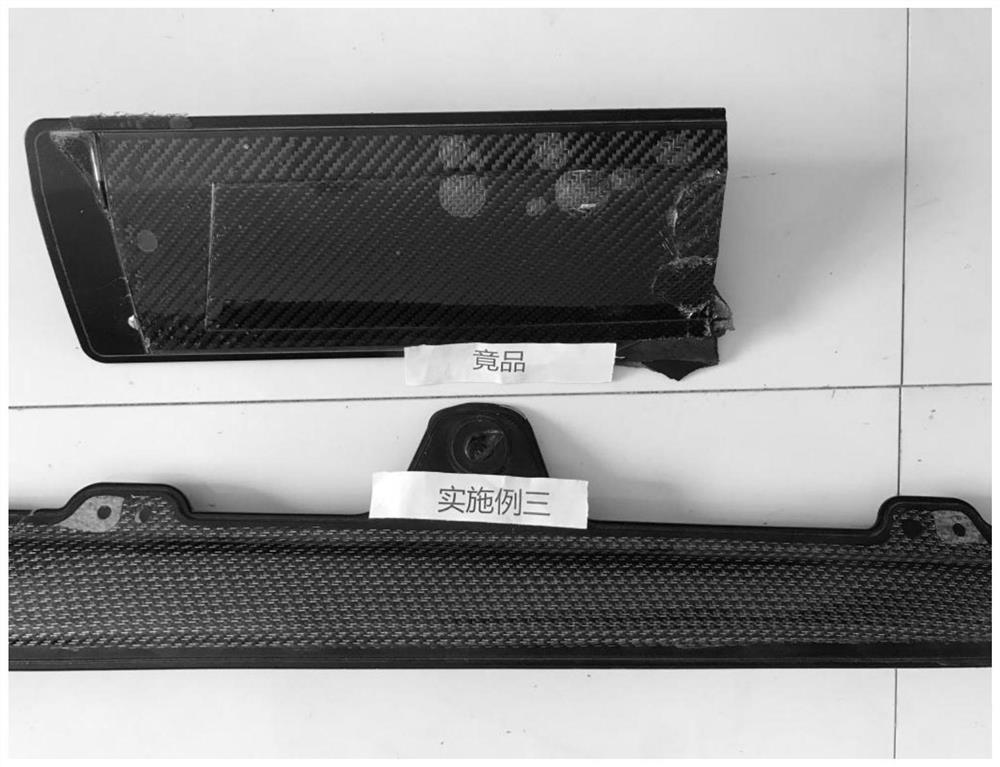

A technology of hydroxyacrylic acid and composition, which is applied in the field of hydroxyacrylic resin material composition and its preparation, which can solve the problems of poor adhesion, white spots, and bubbling between the PUR layer and the carbon fiber layer, and achieve good hardness and strong adhesion , Reduce the effect of bubbling or white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a preparation method of the composition as described above, the preparation method comprising:

[0037] Take the hydroxyacrylic resin, dispersant and ultraviolet light absorber, and mix them to prepare mixture a;

[0038] Add the matte powder to the mixture a, mix to prepare the mixture b;

[0039] Add the anti-settling slurry, drier, and the solvent to the mixture b, and mix to prepare the composition.

[0040] Preferably, in the preparation of the mixture a, the mixing adopts the mode of stirring: the speed of the stirring is 800-1000 rpm, and the duration of the stirring is 5-10 minutes; in the preparation of the mixture b , the mixing adopts the mode of stirring: the speed of the stirring is 1100-1300 rpm, and the duration of the stirring is 15-20 minutes; in the preparation of the composition, the mixing adopts the mode of stirring: the The stirring speed is 800-1000 rpm, and the stirring time is 5-10 minutes.

[...

Embodiment 1

[0059] A high-efficiency adhesion enhancer, consisting of components A, B, and C, wherein component A is the main agent, component B is the polyurethane curing agent, and component C is the diluent. When used, component A: group B Parts: Component C is mixed in a mass ratio of 1:1:1.2.

[0060] 1. Raw material formula and preparation method of component A

[0061] The main ingredient of component A is composed of the following components in mass percentage:

[0062]

[0063] The anti-settling slurry is composed of the following components in mass percentage:

[0064] Xylene 70%,

[0065] Polyamide Wax Anti-Settling Disparlon 6900-20x 30%.

[0066] As a kind of high-efficiency adhesion enhancer component A main agent for automotive interior parts of the present invention, it is prepared by the following steps:

[0067] 1.1 Prepare the anti-settling slurry first: put the polyamide wax anti-settling slurry Disparlon 6900-20x into the dispersion cylinder equipped with xyl...

Embodiment 2

[0094] An adhesion enhancer, consisting of components A, B and C, wherein component A is the main agent, component B is the polyurethane curing agent, and component C is the diluent. When used, component A: component B : Component C is mixed at a mass ratio of 1:1:1.2.

[0095] 1. Raw material formula and preparation method of component A

[0096] The main ingredient of component A is composed of the following components in mass percentage:

[0097]

[0098] The anti-settling slurry is composed of the following components in mass percentage:

[0099] Xylene 70%,

[0100] Polyamide Wax Anti-Settling Disparlon 6900-20x 30%.

[0101] As a kind of high-efficiency adhesion enhancer A component that automobile interior parts of the present invention is used, it is prepared by the following steps:

[0102] 1.1 Prepare the anti-settling slurry first: put the polyamide wax anti-settling slurry Disparlon 6900-20x into the dispersion cylinder equipped with xylene under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com