Nano barium titanate material with low K value and high refractive index and dispersion liquid prepared from nano barium titanate material

A technology with high refractive index and barium titanate, which is applied in the direction of titanate, nanotechnology, alkaline earth metal titanate, etc., can solve the problems of high dielectric constant, high refractive index, low dielectric constant, etc., and achieve wide application Effects of domain and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

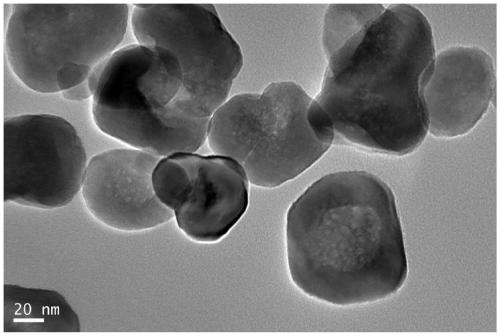

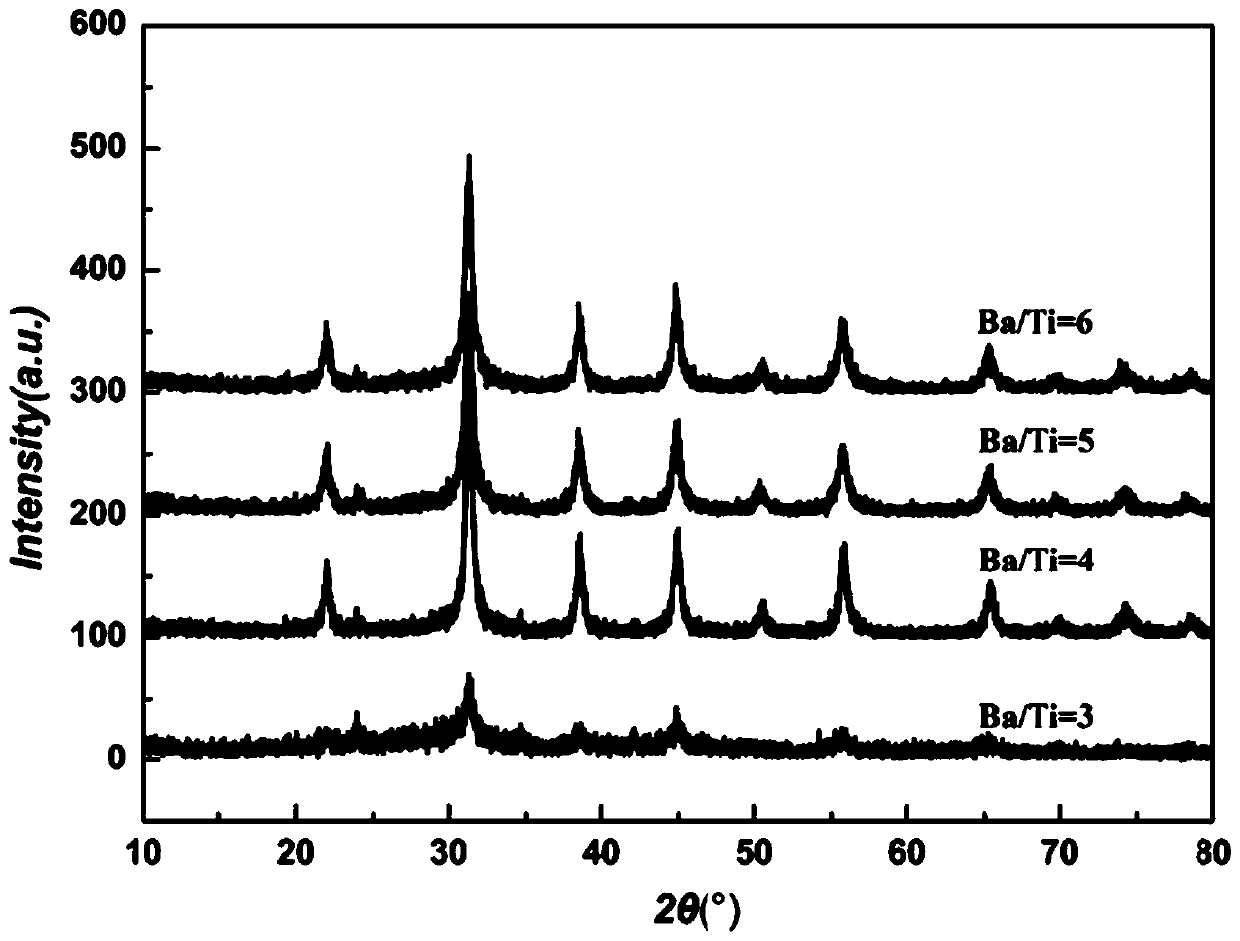

Image

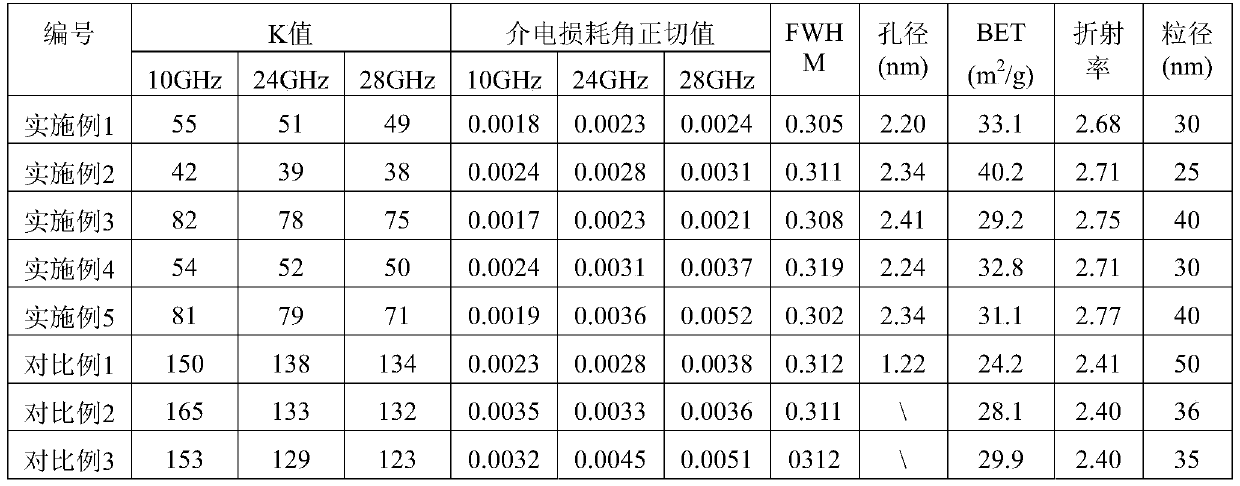

Examples

Embodiment 1

[0040] The preparation method of nanometer barium titanate described in the present embodiment, comprises the steps:

[0041] (1) adding ammoniacal liquor to 2.58kg concentration is the TiCl of 44-46wt% 4 In the solution, adjust the pH of the system to 9 to obtain orthotitanic acid sol; carry out solid-liquid separation of the obtained orthotitanic acid solution, then add 36g of organic base-trimethylamantadine and mix well, and add 1.8kg of octahydrate hydroxide Barium and 27g of barium titanate with a particle size of 20-30nm were used as seed crystals, and the precursor sol was obtained after fully stirring for 1.5h;

[0042] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal kettle, perform hydrothermal synthesis at 200° C. for 6 hours, and stir at a speed of 50 rpm to obtain a barium titanate mixed solution;

[0043] (3) The barium titanate solution obtained in step (2) is cooled, washed with pure water or ethanol, dried at 120-150° C. for 2 hours...

Embodiment 2

[0047] The preparation method of nanometer barium titanate described in the present embodiment, comprises the steps:

[0048] (1) adding ammoniacal liquor to 2.58kg concentration is the TiCl of 44-46wt% 4 In the solution, adjust the system pH=9 to obtain orthotitanic acid sol; the obtained orthotitanic acid solution is subjected to solid-liquid separation, then add 27g organic base-polyacrylic acid, and add 1.8kg octahydrate barium hydroxide and 27g particle diameter of 20-30nm barium titanate was used as the seed crystal, and the precursor sol was obtained after fully stirring for 1.5 hours;

[0049] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal kettle, perform hydrothermal synthesis at 200° C. for 6 hours, and stir at a speed of 50 rpm to obtain a barium titanate mixed solution;

[0050] (3) The barium titanate solution obtained in step (2) is cooled, washed with pure water or ethanol, dried at 120-150° C. for 2 hours, and calcined at 800° C. to...

Embodiment 3

[0054] The preparation method of nanometer barium titanate described in the present embodiment, comprises the steps:

[0055] (1) adding ammoniacal liquor to 2.58kg concentration is the TiCl of 44-46wt% 4 In the solution, adjust the pH of the system to 9 to obtain orthotitanic acid sol; perform solid-liquid separation on the obtained orthotitanic acid solution, and then add 36g of organic base-1,1-dimethyl-3,5-dimethylpiperidine Buzz, and add 1.8kg barium hydroxide octahydrate and 27g barium titanate with a particle size of 20-30nm as seed crystals, and stir thoroughly for 1.5h to obtain the precursor sol;

[0056] (2) Transfer the precursor solution obtained in step (1) to a hydrothermal kettle, perform hydrothermal synthesis at 200° C. for 6 hours, and stir at a speed of 50 rpm to obtain a barium titanate mixed solution;

[0057] (3) The barium titanate solution obtained in step (2) is cooled, washed with pure water or ethanol, dried at 120-150° C. for 2 hours, and calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com