Application of graphene covalently grafted aminobenzene terpyridyl-iron complex in degradation of organic pollutants in Fenton system

A technology for organic pollutants and terpyridine, applied in water pollutants, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve the problem of increasing separation steps, secondary pollution, and no good disposal methods for iron sludge and other problems, achieve good stability, high degradation efficiency, and overcome the effect of iron ion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

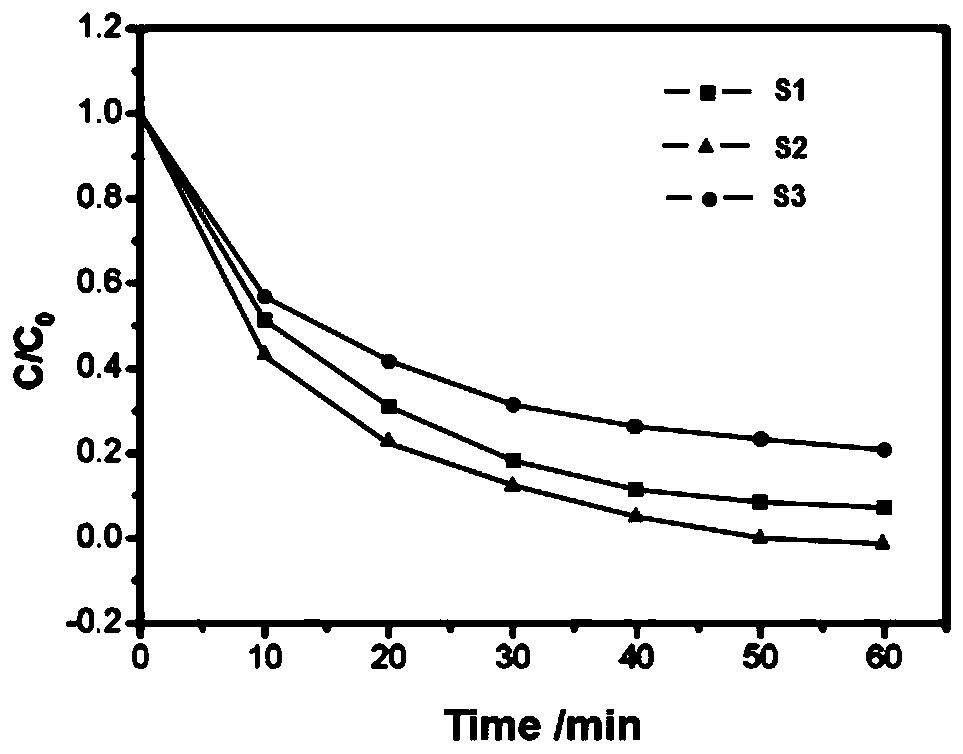

Embodiment 1

[0022] (1) Disperse graphene oxide (GO) in dichloromethane, ultrasonically disperse for 0.5h, add thionyl chloride 5 times the mass of GO dropwise under ultrasonic-assisted conditions, and heat and reflux with Ar gas protection, the reaction temperature 60°C, reaction time 20h, rotary evaporation to remove excess reactants and solvents to obtain acid-chlorinated graphene oxide;

[0023] (2) Dissolve ferrous sulfate in 200ml of water, stir to dissolve, add aminophenyl terpyridine ligand, the molar ratio of ferrous sulfate to ligand is 1:1, stir magnetically for 2 hours to obtain a homogeneous mixture, transfer the above mixture into In a stainless steel reaction kettle lined with polytetrafluoroethylene, the temperature was raised to 130 ° C for 36 hours, and after the reaction was completed, it was naturally cooled to room temperature, filtered, and washed to obtain the aminobenzene terpyridine-iron complex;

[0024] (3) Dissolving the aminobenzene terpyridine-iron complex pre...

Embodiment 2

[0026] (1) Disperse graphene oxide (GO) in dichloromethane, ultrasonically disperse for 1 h, add thionyl chloride 7 times the mass of GO dropwise under ultrasonic-assisted conditions, and heat and reflux with Ar gas protection, the reaction temperature is 60 ℃, reaction time 20h, rotary evaporation to remove excess reactants and solvents, to obtain acid-chlorinated graphene oxide;

[0027] (2) Dissolve ferrous sulfate in 200ml of water, stir to dissolve, add aminophenyl terpyridine ligand, the molar ratio of ferrous sulfate to ligand is 1:1, stir magnetically for 2 hours to obtain a homogeneous mixture, transfer the above mixture into In a stainless steel reaction kettle lined with polytetrafluoroethylene, the temperature was raised to 130 ° C for 36 hours, and after the reaction was completed, it was naturally cooled to room temperature, filtered, and washed to obtain the aminobenzene terpyridine-iron complex;

[0028] (3) Dissolving the aminobenzene terpyridine-iron complex ...

Embodiment 3

[0030] (1) Disperse graphene oxide (GO) in dichloromethane, ultrasonically disperse for 1 h, add thionyl chloride 10 times the mass of GO dropwise under ultrasonic-assisted conditions, and heat and reflux with Ar gas protection, the reaction temperature is 60 ℃, reaction time 20h, rotary evaporation to remove excess reactants and solvents, to obtain acid-chlorinated graphene oxide;

[0031](2) Dissolve ferrous sulfate in 200ml of water, stir to dissolve, add aminophenyl terpyridine ligand, the molar ratio of ferrous sulfate to ligand is 1:1, stir magnetically for 2 hours to obtain a homogeneous mixture, transfer the above mixture into In a stainless steel reaction kettle lined with polytetrafluoroethylene, the temperature was raised to 130 ° C for 36 hours, and after the reaction was completed, it was naturally cooled to room temperature, filtered, and washed to obtain the aminobenzene terpyridine-iron complex;

[0032] (3) Dissolving the aminobenzene terpyridine-iron complex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com