Preparation method of modified graphene oxide/natural rubber high-heat-conducting composite material

A technology of natural rubber and composite materials, which is applied in the field of preparation of modified graphene oxide/natural rubber high thermal conductivity composite materials, which can solve problems such as low thermal conductivity, improve thermal conductivity, facilitate thermal conduction network, and improve thermal conductivity Promoted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

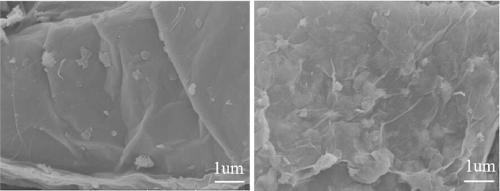

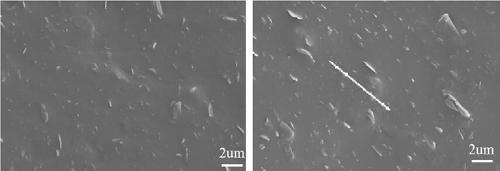

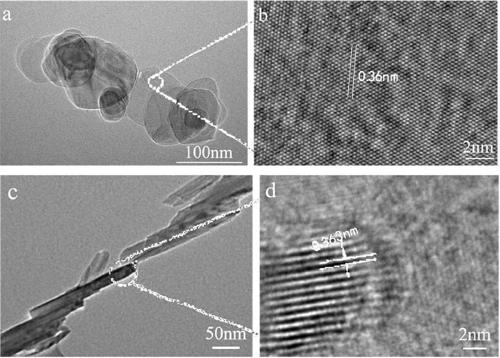

Image

Examples

Embodiment 1

[0038] A preparation method of modified graphene oxide / natural rubber high thermal conductivity composite material, comprising the following steps:

[0039] (1) Preparation of hexagonal boron nitride nanosheets by ultrasonic assisted exfoliation

[0040] Weigh 10 g of hexagonal boron nitride and pretreat it in an oven at 120° C. for 12 hours. Measure 500ml of absolute ethanol, mix ethanol and isopropanol according to the volume ratio of 5:3, use stirring method to make the mixture uniform, then add the dried hexagonal boron nitride into the mixed solvent, and stir thoroughly; Add the mixed solution into the three-necked flask, put the three-necked flask into the ultrasonic reaction apparatus, and configure the mechanical stirring device at the same time, set the temperature of the ultrasonic reaction apparatus to 60°C, the ultrasonic power to 120W, and the reaction time to 12h, turn on the ultrasonic reaction apparatus and mechanical stirring device. During the reaction proc...

Embodiment 2

[0047] A preparation method of modified graphene oxide / natural rubber high thermal conductivity composite material, comprising the following steps:

[0048] (1) Preparation of hexagonal boron nitride nanosheets by ultrasonic assisted exfoliation

[0049] Weigh 10 g of hexagonal boron nitride and pretreat it in an oven at 100° C. for 24 hours. Measure 500ml of absolute ethanol, mix ethanol and ethanolamine according to the volume ratio of 5:2, use stirring method to make the mixture even, then add the dried hexagonal boron nitride into the mixed solvent, stir fully; mix Add the solution into the three-necked flask, put the three-necked flask into the ultrasonic reaction apparatus, and configure the mechanical stirring device at the same time, set the temperature of the ultrasonic reaction apparatus to 80°C, the ultrasonic power to 200W, and the reaction time to 8h, turn on the ultrasonic reaction apparatus and mechanical Stirring device. During the reaction process, 0.3 g of ...

Embodiment 3

[0056] A preparation method of modified graphene oxide / natural rubber high thermal conductivity composite material, comprising the following steps:

[0057] (1) Preparation of hexagonal boron nitride nanosheets by ultrasonic assisted exfoliation

[0058] Weigh 10 g of hexagonal boron nitride and pretreat it in an oven at 80° C. for 36 h. Measure 500ml of absolute ethanol, mix ethanol and isopropanol at a volume ratio of 5:1, and stir to make the mixture even, then add the dried hexagonal boron nitride into the mixed solvent, and stir thoroughly; Add the mixed solution into the three-necked flask, put the three-necked flask into the ultrasonic reaction device, and configure the mechanical stirring device at the same time, set the temperature of the ultrasonic reaction device to 30°C, the ultrasonic power to 200W, and the reaction time to 6h, turn on the ultrasonic reaction device and mechanical stirring device. During the reaction process, 0.5 g of silane coupling agent KH570...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com