Wear-resistant and corrosion-resistant ceramic glaze as well as preparation method and application thereof

A ceramic glaze and anti-corrosion technology, which is applied in the field of ceramics, can solve the problems of shortening the service life of ceramic tiles, unsatisfactory, and wear, and achieve excellent wear and corrosion resistance, acid and alkali resistance, and improved wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

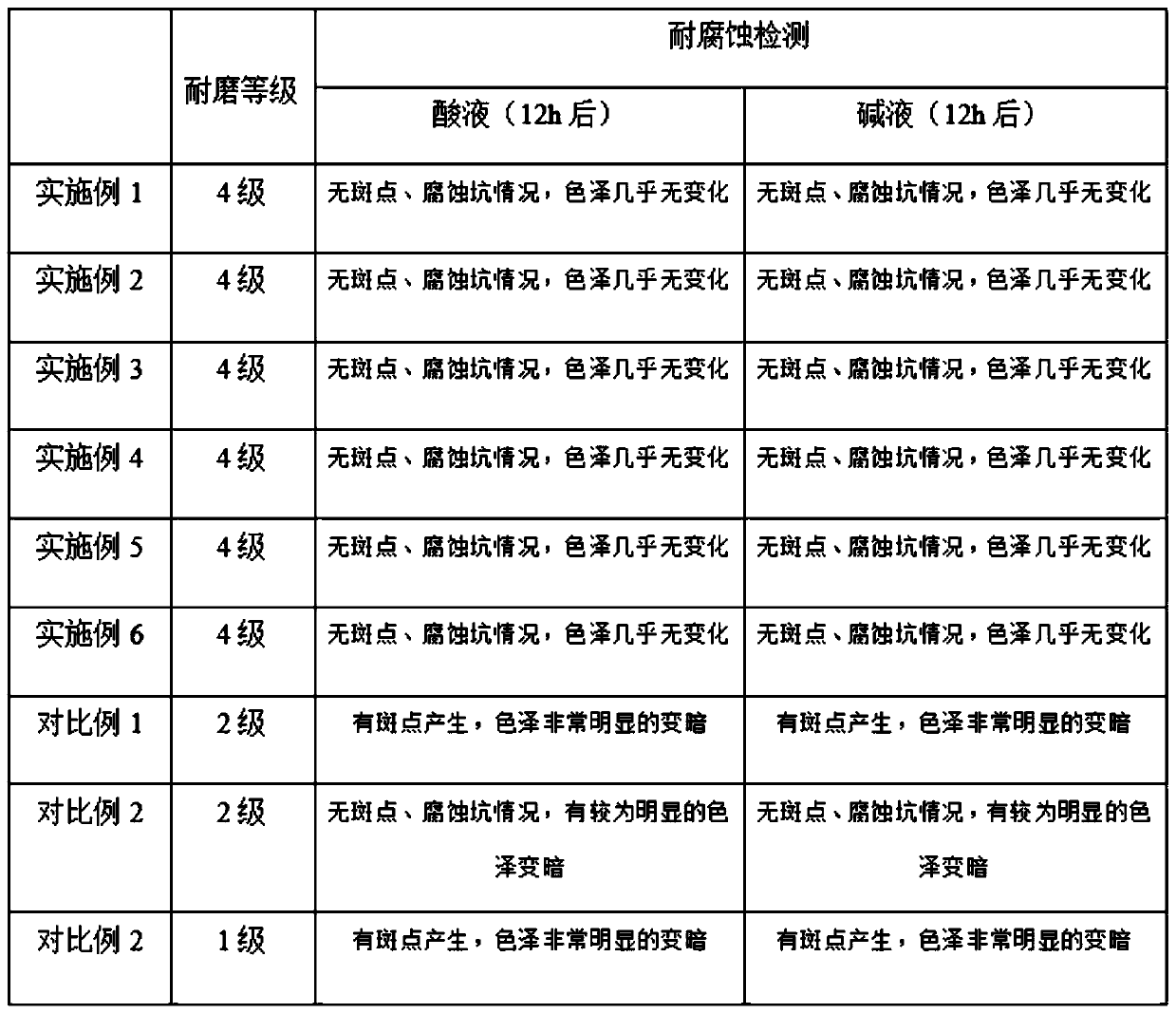

Examples

Embodiment 1

[0018] Mix 10Kg spodumene, 5Kg osmanthus gemstone and 15Kg white corundum evenly, crush them, pass through a 100 mesh sieve, then add 5Kg kaolin, 5Kg mica powder, 10Kg nickel oxide, 10Kg chromium oxide, 2Kg boron oxide, 2Kg tantalum oxide, 2Kg oxide Zirconium, 2Kg cobalt oxide, 2Kg nano-zinc oxide, 2Kg nano-zirconium silicate, 5Kg polyethylene wax powder and appropriate amount of deionized water are put into a high-speed mixer for stirring and mixing for 2 hours; The temperature is 180r / min, and after drying, it is passed through a 150-mesh sieve to obtain a wear-resistant and corrosion-resistant ceramic glaze.

Embodiment 2

[0020] Mix 12Kg spodumene, 20Kg osmanthus gemstone and 0Kg white corundum evenly, crush them, pass through a 100 mesh sieve, then add 20Kg kaolin, 15Kg mica powder, 25Kg nickel oxide, 25Kg chromium oxide, 5Kg boron oxide, 5Kg tantalum oxide, 5Kg oxide Zirconium, 5Kg cobalt oxide, 5Kg nano-zinc oxide, 5Kg nano-zirconium silicate, 8Kg polyethylene wax powder and appropriate amount of deionized water were put into a high-speed mixer for stirring and mixing for 2 hours; The temperature is 150r / min, and after drying, it is passed through a 150-mesh sieve to obtain a wear-resistant and corrosion-resistant ceramic glaze.

Embodiment 3

[0022] Mix 12Kg spodumene, 5Kg osmanthus gemstone and 15Kg white corundum evenly, crush them, pass through a 100 mesh sieve, then add 20Kg kaolin, 10Kg mica powder, 20Kg nickel oxide, 20Kg chromium oxide, 3Kg boron oxide, 3Kg tantalum oxide, 3Kg oxide Zirconium, 3Kg cobalt oxide, 3Kg nano-zinc oxide, 3Kg nano-zirconium silicate, 6Kg polyethylene wax powder and appropriate amount of deionized water were put into a high-speed mixer for stirring and mixing for 2 hours; The temperature is 150r / min, and after drying, it is passed through a 150-mesh sieve to obtain a wear-resistant and corrosion-resistant ceramic glaze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com