Hydrocarbon conversion processes using metal carbide nanomaterial catalysts

A metal carbide and hydrocarbon technology, which is applied in the field of hydrocarbon conversion process using metal carbide nanomaterial catalyst, can solve the problem of failing to provide catalyst formula and activity, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

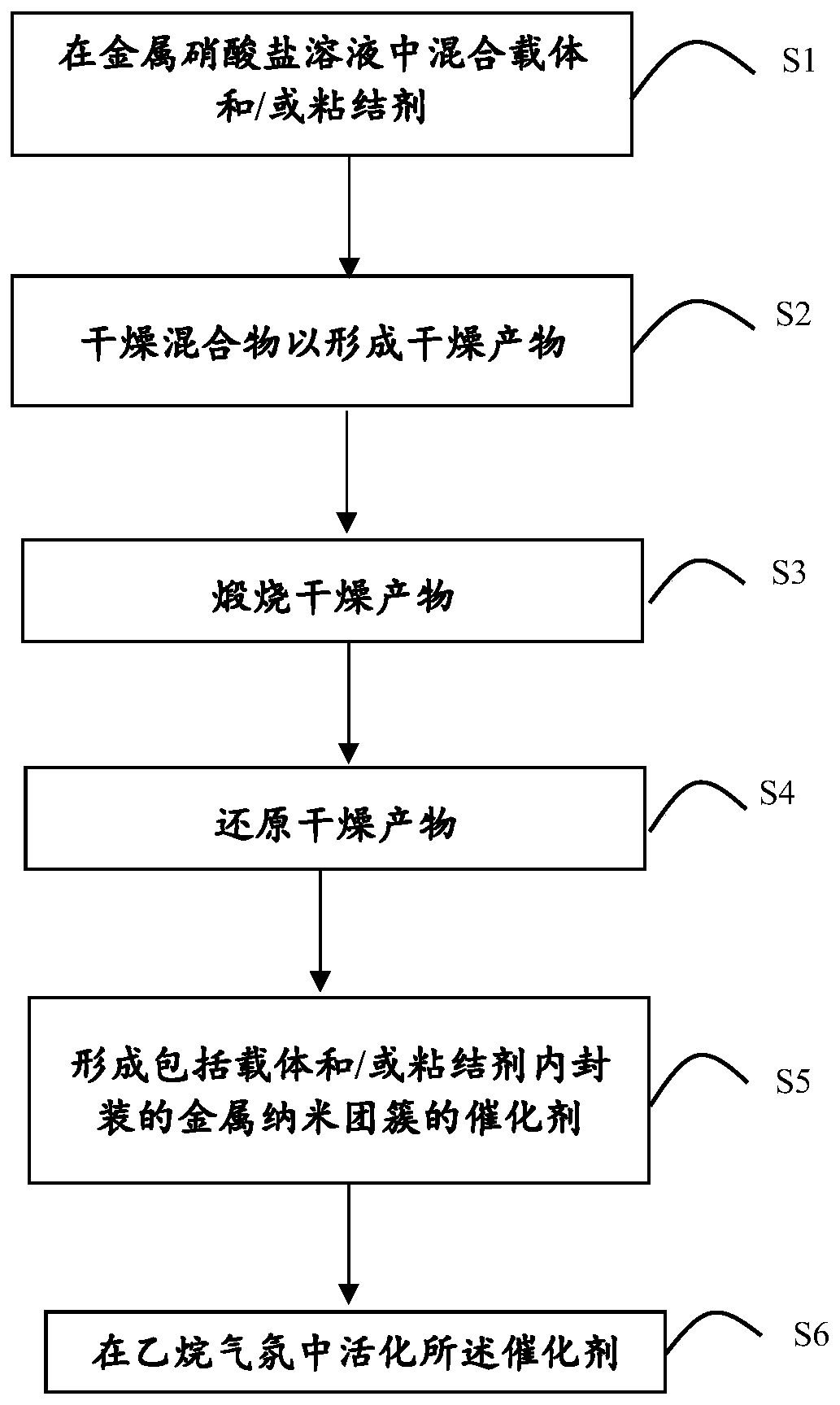

Method used

Image

Examples

Embodiment 1

[0057] 5 g of ZSM-5 powder (with a silicon to aluminum ratio of 30) was mixed with an amount of Pt(NO3)2 in solution. The mixture was stirred at room temperature for 1 hour, then heated to 80 °C in a rotary evaporator to obtain a dry product, followed by air calcination at 550 °C for 4 hours. The powder was then reduced in situ in hydrogen at 630°C for 1 hour and cooled to room temperature (eg, between 20-25°C) in a hydrogen atmosphere. The powder was then pressed and sieved to 20x40 mesh. The resulting product is denoted Catalyst B and contains 500 ppm Pt. Characterization measurements were then performed on Catalyst B to determine its characteristics.

Embodiment 2

[0059] The powder was prepared using the same procedure as Catalyst B in Example 1, but after reduction in a hydrogen atmosphere, the powder was cooled to 400°C in a hydrogen atmosphere, followed by an inert gas purge at 400°C for 10 minutes, and then at 300-500°C Activated in ethane (50% nitrogen balance) at a temperature of . After ethane activation, the powder is cooled to 100° C. under a stream of ethane and further cooled to room temperature in an inert gas atmosphere, such as nitrogen. The resulting product, denoted Catalyst C, also contained 500 ppm Pt.

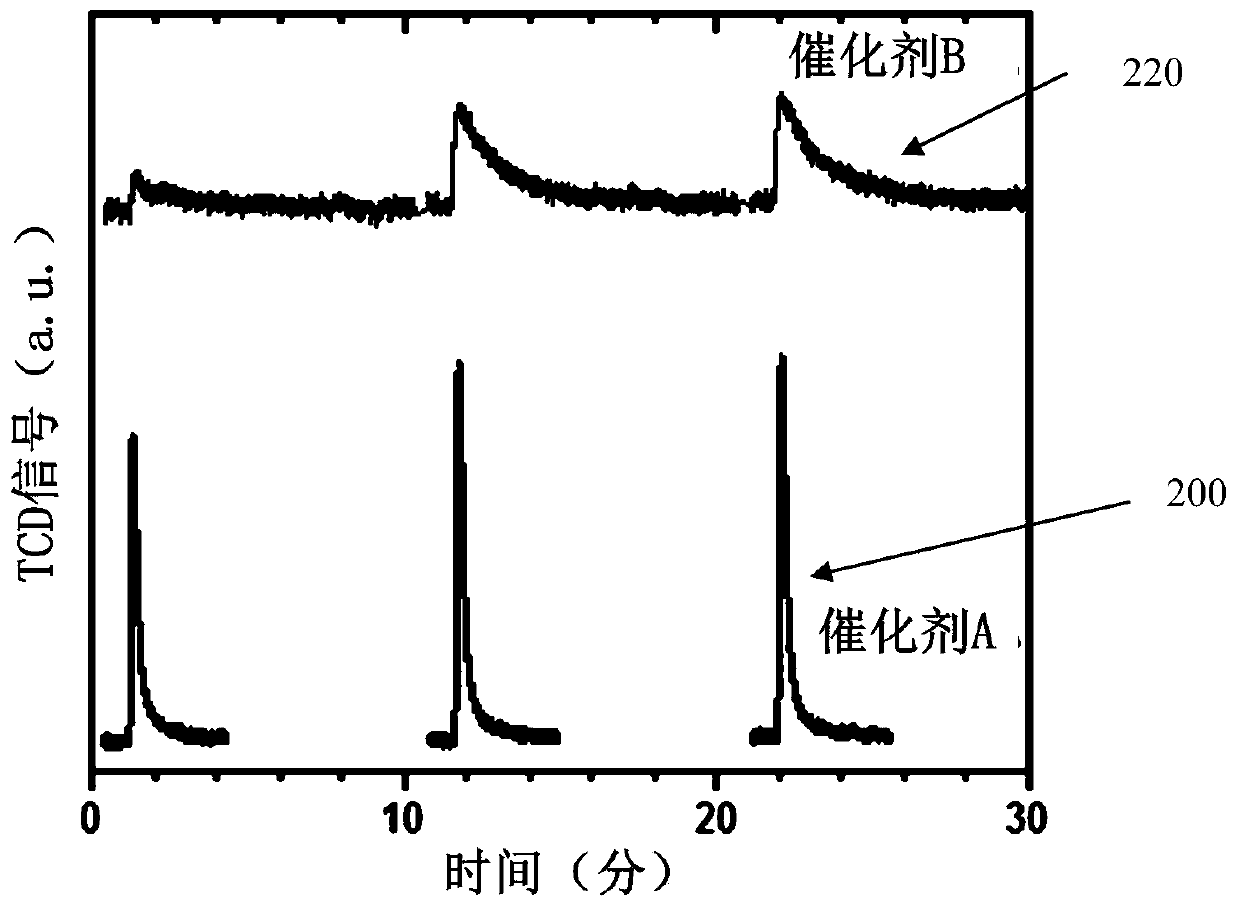

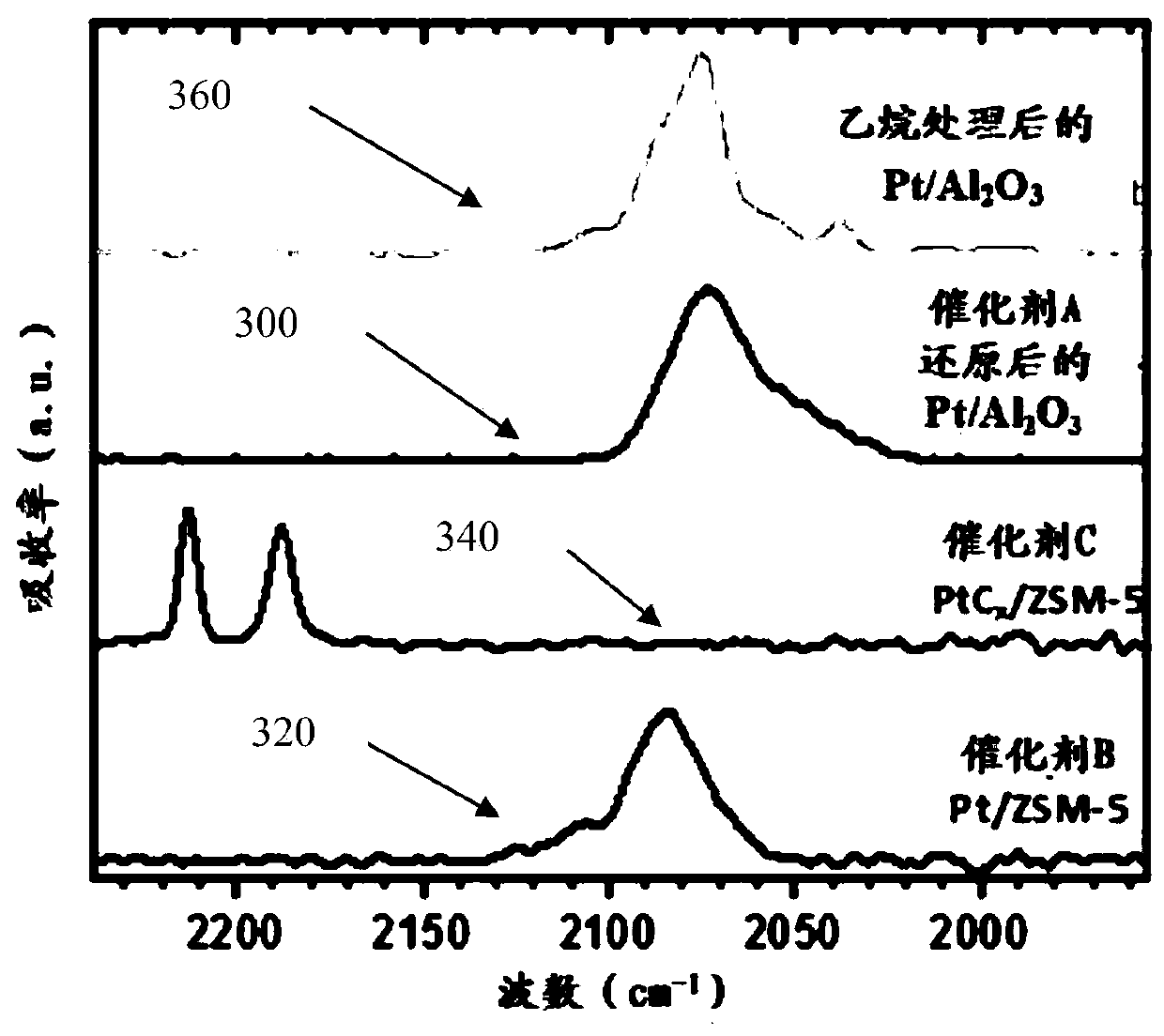

[0060] Catalysts A, B, and C were then characterized by testing and analyzing the platinum dispersion of the catalysts in the catalysts by dynamic CO chemisorption measurements (chemisorption), where diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS, diffuse reflectance infrared Fourier transform spectroscopy) and X-ray absorption near edge structure (XANES, X-ray absorption near edge structure) to stu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com