Composite solid electrolyte film and preparation and application thereof

A technology of solid electrolyte and thin film, which is applied in the direction of electrolyte, non-aqueous electrolyte battery, electrolyte immobilization/gelation, etc. It can solve the problems of low conductivity of polymer solid electrolyte, unstable electrochemical properties, poor battery safety, etc. Achieve the effects of rapid continuous transmission suppression, low cost, and suppression of concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

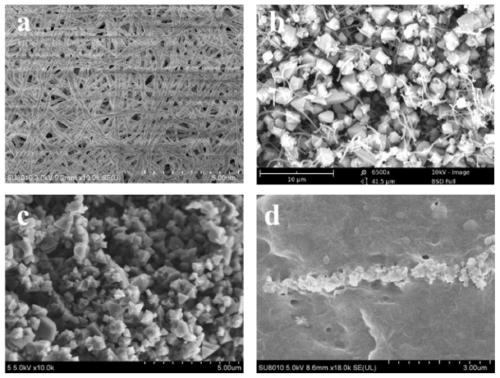

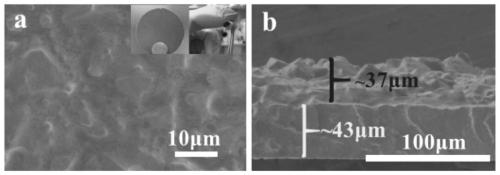

[0053] (1) According to a certain molar ratio, take respectively 2.56g vacuum-dried lithium nitrate (Alfa Aisha, >99.9%), 6.50g vacuum-dried lanthanum nitrate hexahydrate (Chinese medicine, >99.9%), 3.36g Zirconium n-butoxide (TCI, >99.0%) and) 0.338g niobium pentachloride (Sigma-Aldrich, >99.99%), placed in a 250mL volumetric flask. Weigh 200mL N,N-dimethylamide (Chinese medicine, >99.0%) and 50mL acetic acid (Chinese medicine, >98.0%) respectively in a beaker, add the mixed solution of the two into the volumetric flask, constant volume, magnetic stirring until the solute is completely dissolved. Weigh 20 g of the above dissolved solution and 3 g of PVP (Sigma-Aldrich, molecular weight 1300000) into a 100 mL beaker, and magnetically stir until the PVP is completely dissolved. During the electrospinning process, the voltage was 20kV, the distance from the needle to the receiving plate was 10cm, the advancing speed was 1mL / h, and the spinning time was 20h to obtain the LLZN na...

PUM

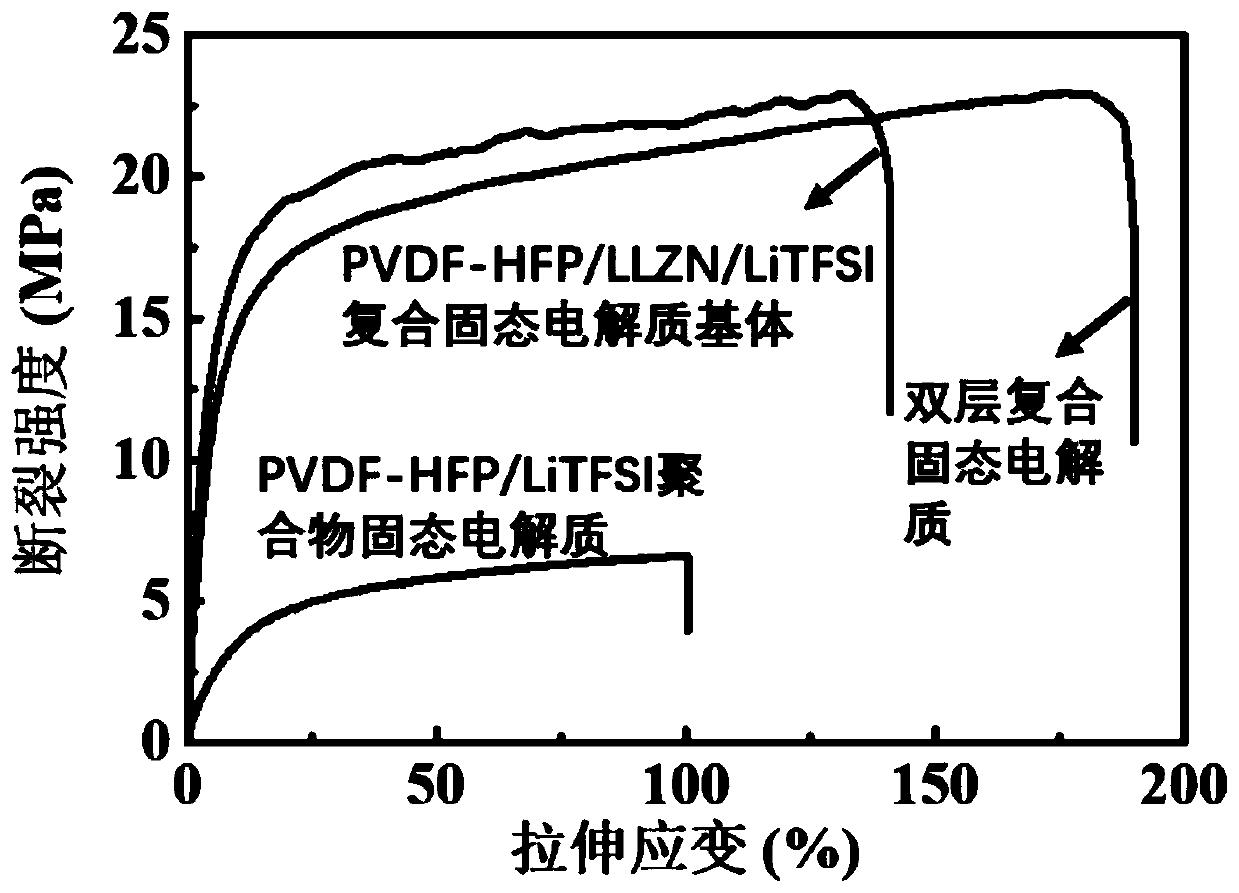

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com