Black phosphorus nanosheet/gold nanoparticle composite material and preparation method and application thereof

A gold nanoparticle and composite material technology, which is applied in the field of black phosphorus nanosheet/gold nanoparticle composite material and its preparation to achieve the effect of high-efficiency loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of black phosphorus nanosheets:

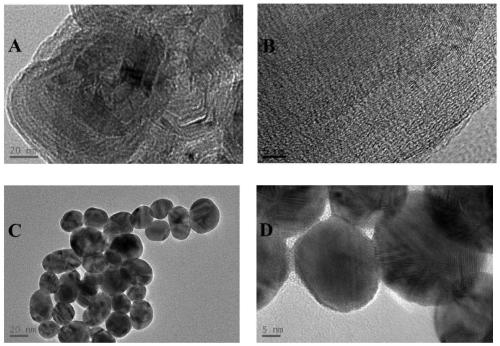

[0050]Disperse 5.0 mg of black phosphorus powder in 30.0 mL of N-methylpyrrolidone solution and sonicate in an ice bath for 11 h. After centrifugation at 2,000 rpm for 5 min to remove remaining unexfoliated particles in the mixture, the supernatant was collected, then centrifuged at 10,000 rpm for 5 min, and washed twice with ultrapure water to obtain a brown suspension of black phosphorus nanosheets. Take a small amount of the solution and observe it under a scanning electron microscope. figure 1 A. figure 1 B shows the black phosphorus nanosheet structure.

Embodiment 2

[0052] Preparation of gold nanoparticles:

[0053] When 99.0 mL of ultrapure water was heated to 60 °C in the round bottom flask, 1.0 mL of 1 wt.% chloroauric acid solution was added immediately. When the mixed solution starts to boil, add 4.0 mL of trisodium citrate solution. After reacting for 12 minutes, it was naturally cooled to room temperature to obtain a gold nanoparticle dispersion. Take a small amount of the solution and observe it under a scanning electron microscope. figure 1 C. figure 1 D shows the gold nanoparticle structure.

Embodiment 3

[0055] The inhibitory ability of each component to tongue squamous cell carcinoma cell SCC-9 was detected when each composite material was used as a drug carrier:

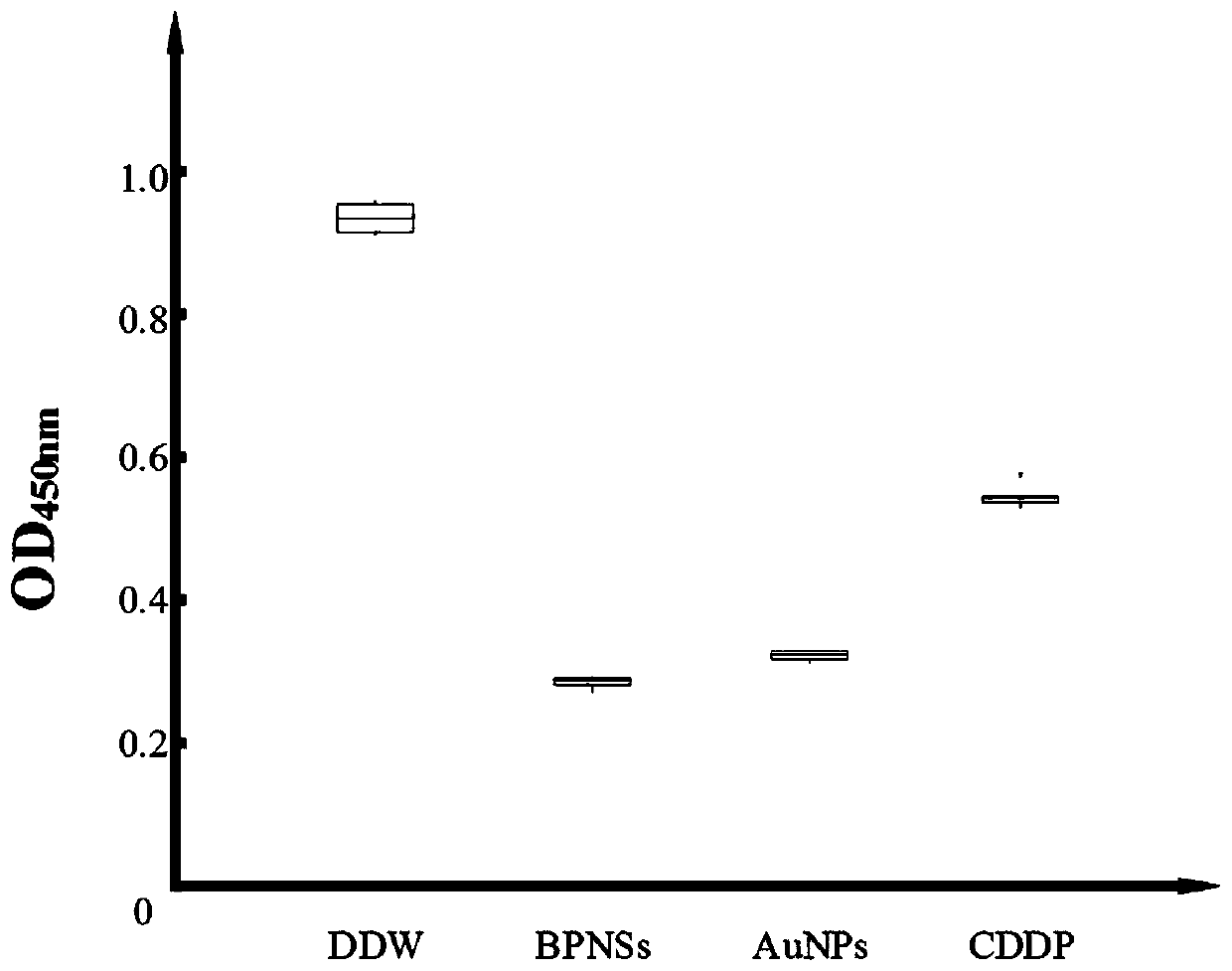

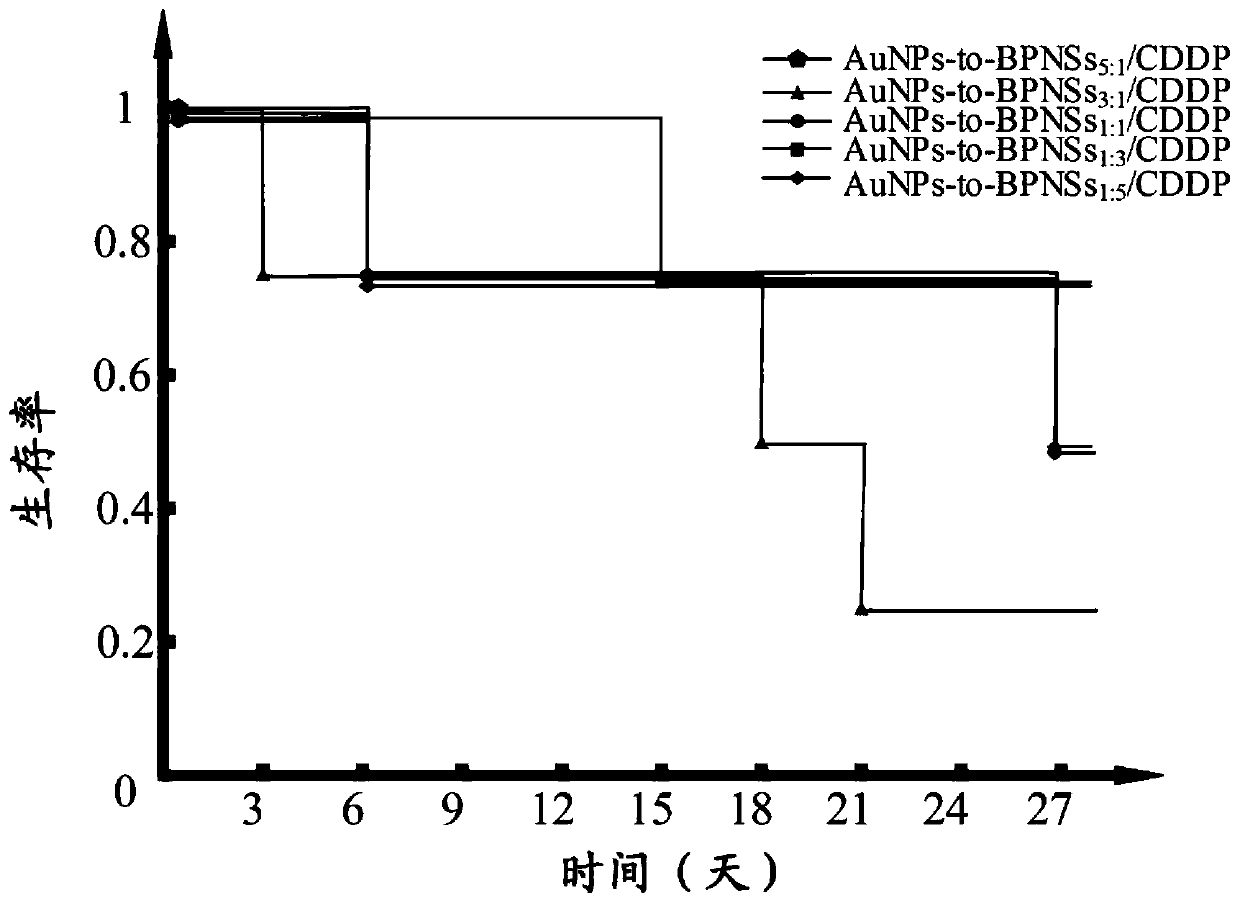

[0056] Extract, digest and count SCC-9 cells in the logarithmic growth phase, and divide into 5×10 4 Cells / mL were seeded into 96-well plates at 100 μL per well. Five replicate wells were designed for each group. After the cells adhered, they were treated with different drug-containing media (50 μg / mL black phosphorus nanosheet dispersion (BPNSs), 50 μg / mL gold nanoparticle dispersion (AuNPs), 2 mg / mL cisplatin solution (CDDP) and ultrapure water (DDW)) for 4 hours. After removal of the drug-containing medium, 100 μL of medium (containing 10 μL of LCCK-8 reagent) was added to each well. at 37°C and 5% CO 2 After 4 hours of incubation under high temperature, analyze the optical density (OD) value at 450nm place by Microplate Reader, get as follows figure 2 , The distribution of optical density values shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com