Adsorption purification device for industrial oil-containing waste gas treatment

A waste gas treatment and purification device technology, which is applied in the direction of gaseous effluent wastewater treatment, combined devices, multi-stage water treatment, etc., can solve the problems of affecting the adsorption and filtration effect, affecting the internal cleaning of the treatment equipment, and limited usability, so as to improve the adsorption Filtering effect, effect of improving reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

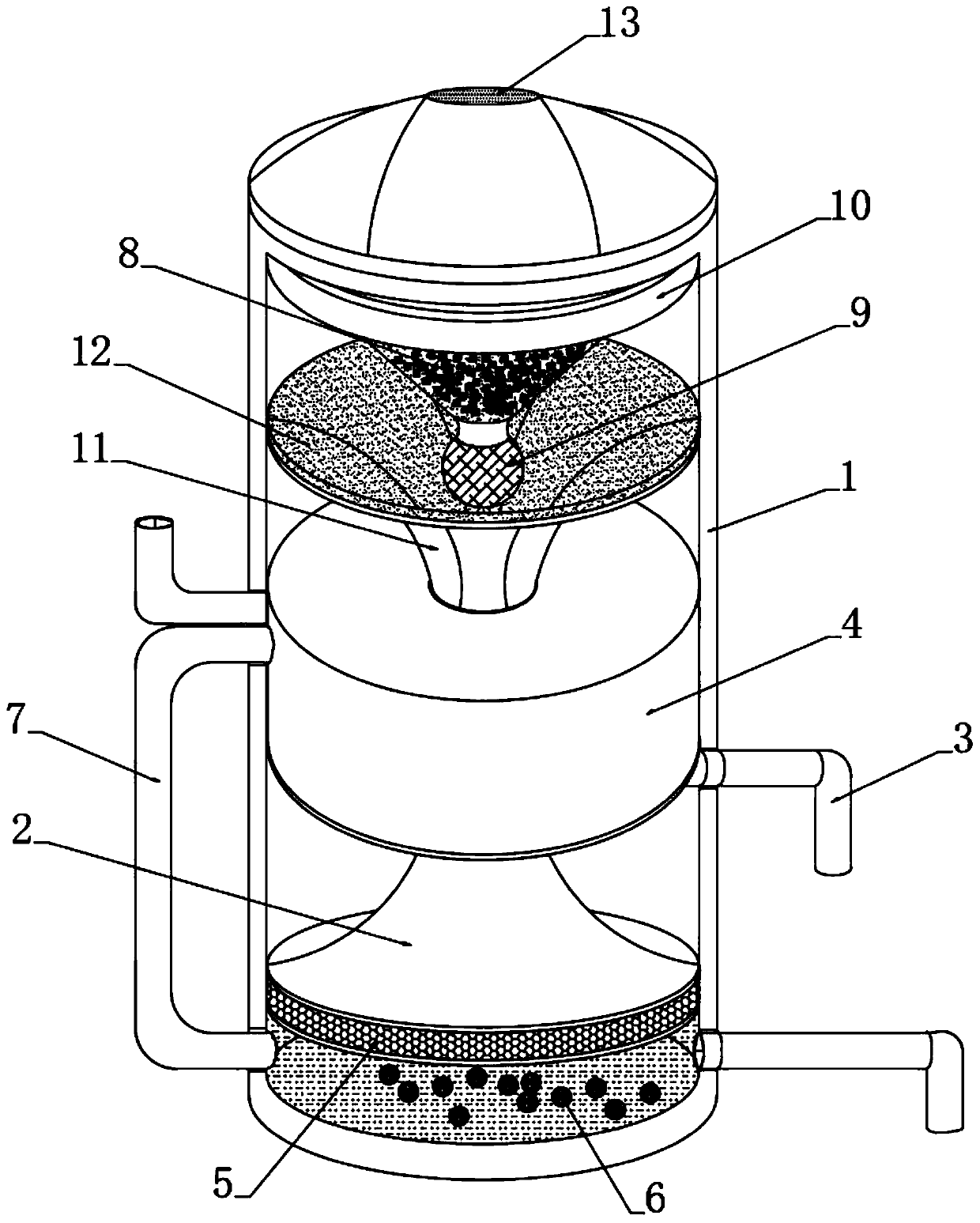

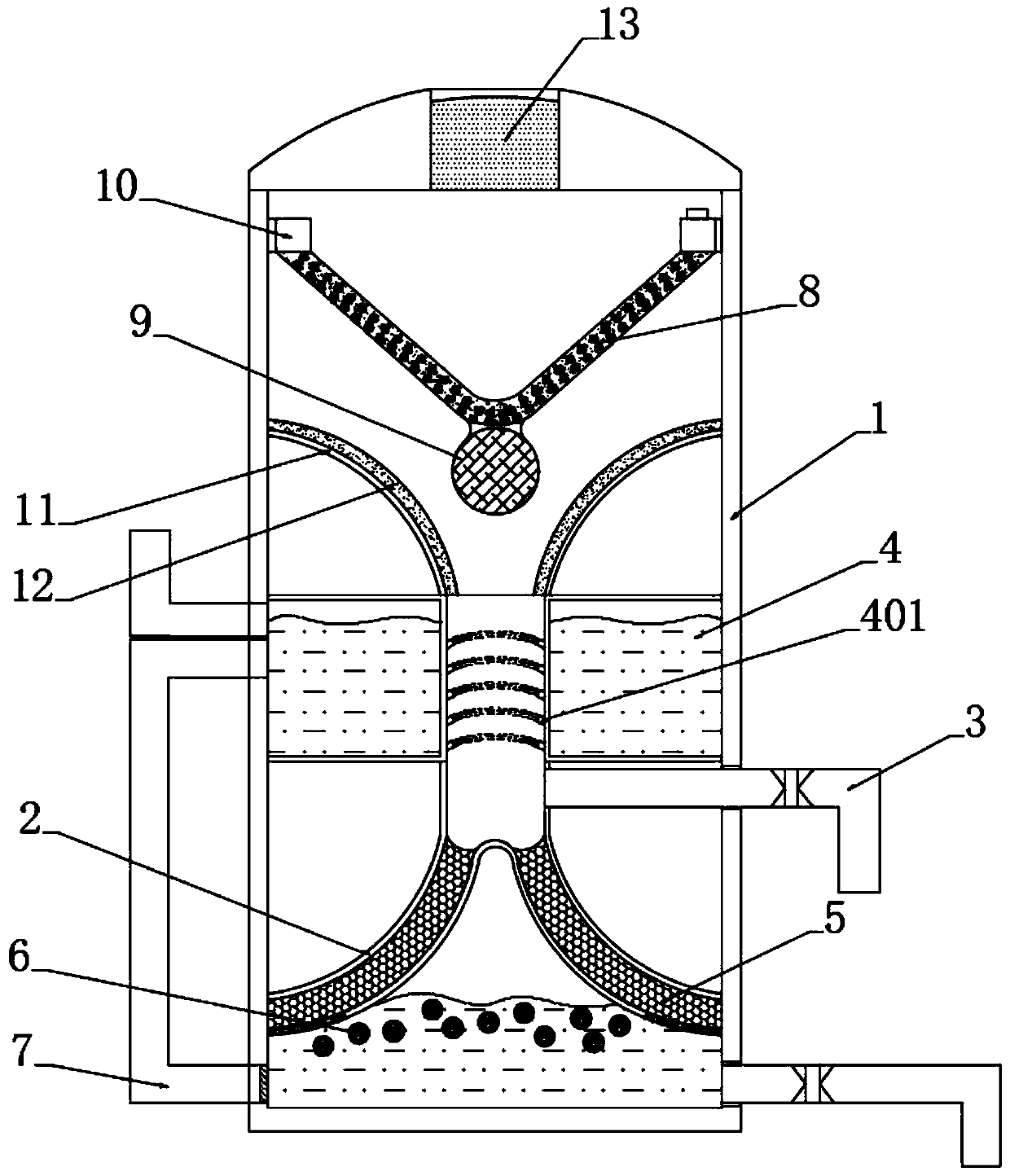

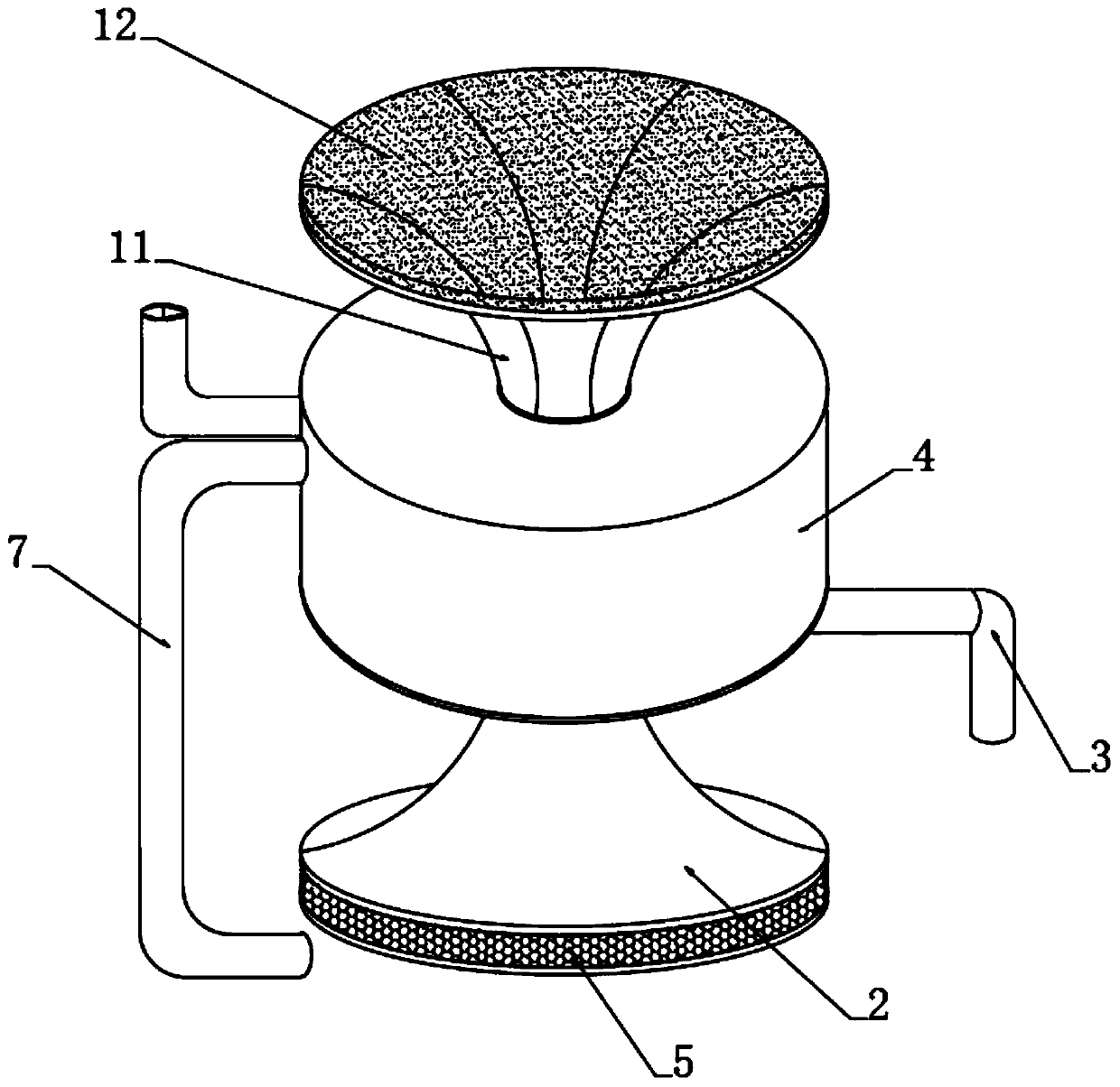

[0041] see Figure 1-5 , an adsorption and purification device for industrial oily waste gas treatment, comprising a treatment cylinder 1 and a straw hat-shaped diversion box 2 fixedly installed in the treatment cylinder 1, the outer end of the treatment cylinder 1 is provided with an inner end connected to the straw hat-shaped diversion box 2 The air intake pipe 3 on the side wall, the top of the straw hat-shaped diversion box 2 is fixedly connected with a hollow washing box 4, and a hollow spray chamber is provided in the middle of the hollow washing box 4, and the inner wall of the hollow spray chamber is arranged along the direction of its axis. A plurality of 401 are installed in a ring, and the outer end of the processing cylinder 1 is fixedly inserted with a water inlet pipe connected to the inner wall of the hollow washing box 4. A filling cavity is opened inside the straw hat-shaped diversion box 2, and the filling cavity is filled with honeycomb ceramics. Adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com