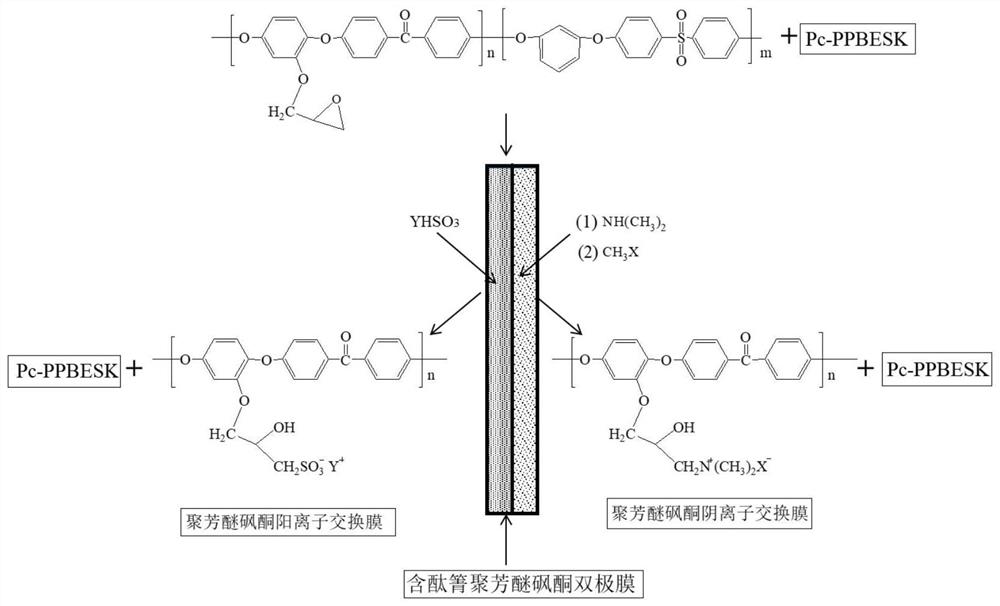

A preparation method of monolithic polyaryl ether sulfone ketone bipolar membrane containing phthalocyanine water dissociation catalytic group

A polyarylether sulfone ketone and bipolar membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor grafting uniformity, increased synthesis steps, low grafting rate, etc., and achieve transmembrane voltage Low, low resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

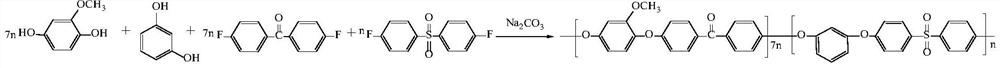

[0045] (1) In a three-necked flask, add 8.6898g (70mmol) of o-methylhydroquinone, 1.1101g (10mmol) of resorcinol, 15.2749g (70mmol) of difluorobenzophenone, and difluorodiphenylsulfone 2.5425g (10mmol), anhydrous potassium carbonate 13.2664g (90mmol), toluene 320mL, DMAc 400mL, react in a nitrogen atmosphere at 140°C for 3h, then raise the temperature to 160°C for 8h, immediately pour the reaction solution into deionized water under stirring Precipitate, filter. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours, filtered, and dried in a vacuum oven at 80°C for 10 hours to obtain a product containing methoxy polyarylether sulfone ketone.

[0046]

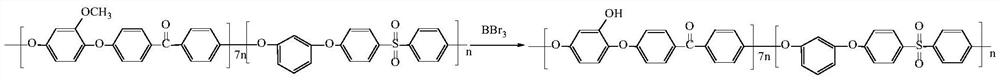

[0047] (2) Weigh 5.0 g of methoxy polyarylether sulfone ketone polymer into a 250 mL three-necked flask, install a constant pressure dropping funnel, and protect it with a nitrogen balloon after vacuuming. Add 120mL of pre-dried dichloromethane to dissolve the polymer, and add 3.6mL of b...

Embodiment 2

[0061] (1) Preparation of polyarylether sulfone ketone containing methoxy: In a three-necked flask, add 5.1369g (30mmol) of 2,5-dimethoxyhydroquinone, 1.1101g (10mmol) of resorcinol, Difluorodiphenyl sulfone 7.6275g (30mmol), difluorobenzophenone 2.1820g (10mmol), anhydrous potassium carbonate 6.9002g (50mmol), toluene 160mL, DMAc200mL, in N 2 React at 140°C for 3 hours in the atmosphere, then raise the temperature to 175°C for 9 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours, filtered, and dried in a vacuum oven at 80°C for 10 hours to obtain a product containing methoxy polyarylether sulfone ketone.

[0062]

[0063](2) Weigh 5.0 g of methoxy-containing polyarylether sulfone ketone polymer into a 250 mL three-neck flask, install a constant-pressure dropping funnel, and protect it with a nitrogen balloon after vacuum...

Embodiment 3

[0075] (1) Preparation of polyarylether sulfone ketone containing methoxy: Add 2.0223g (10mmol) of 2,3,5-trimethoxyhydroquinone and 1.1101g (10mmol) of resorcinol to a three-necked flask in sequence. , difluorodiphenyl sulfone 2.5425g (10mmol), difluorobenzophenone 2.1820g (10mmol), anhydrous potassium carbonate 2.07g (15mmol), toluene 160mL, DMAc200mL, in N 2 React at 140°C for 3 hours in the atmosphere, then raise the temperature to 170°C for 6 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. The filtered precipitate was soaked in deionized water, soaked in running water for 24 hours, filtered, and dried in a vacuum oven at 80°C for 10 hours to obtain a product containing methoxy polyarylether sulfone ketone.

[0076]

[0077] (2) Weigh 5.0 g of methoxy-containing polyarylether sulfone ketone polymer into a 250 mL three-neck flask, install a constant-pressure dropping funnel, and protect it with a nitrogen ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com