Nitrogen-doped porous carbon material derived from zeolite imidazole framework material and preparation method of nitrogen-doped porous carbon material

A nitrogen-doped porous carbon and zeolite imidazole framework technology, applied in the field of non-metallic materials, can solve problems such as poor performance, weak water stability, secondary pollution, etc., and achieves good thermal stability, fewer types of raw materials, and efficient adsorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

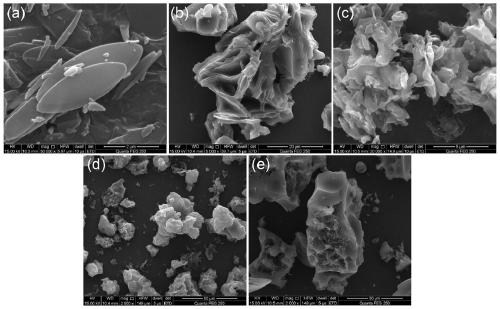

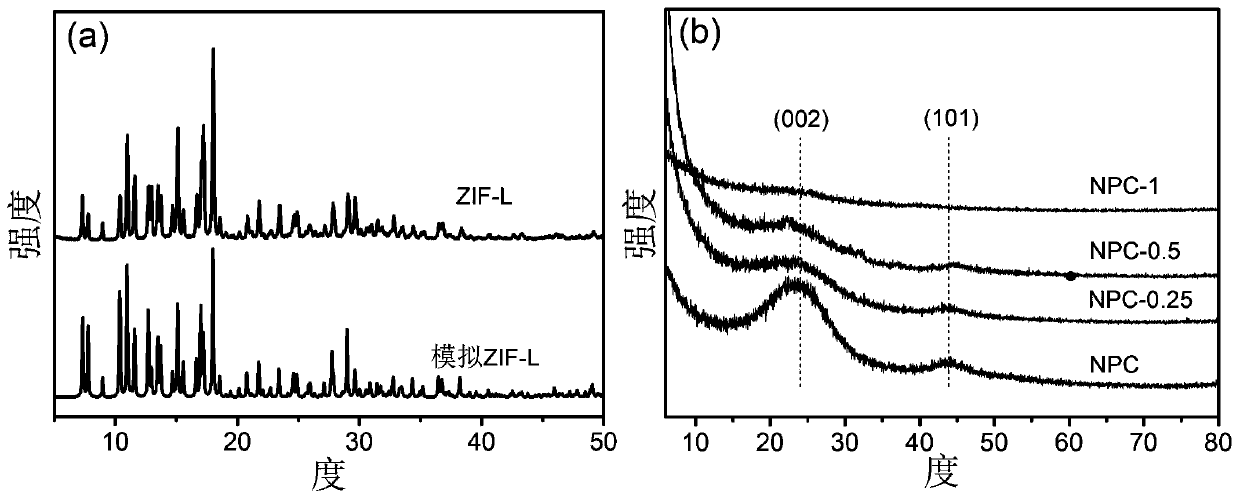

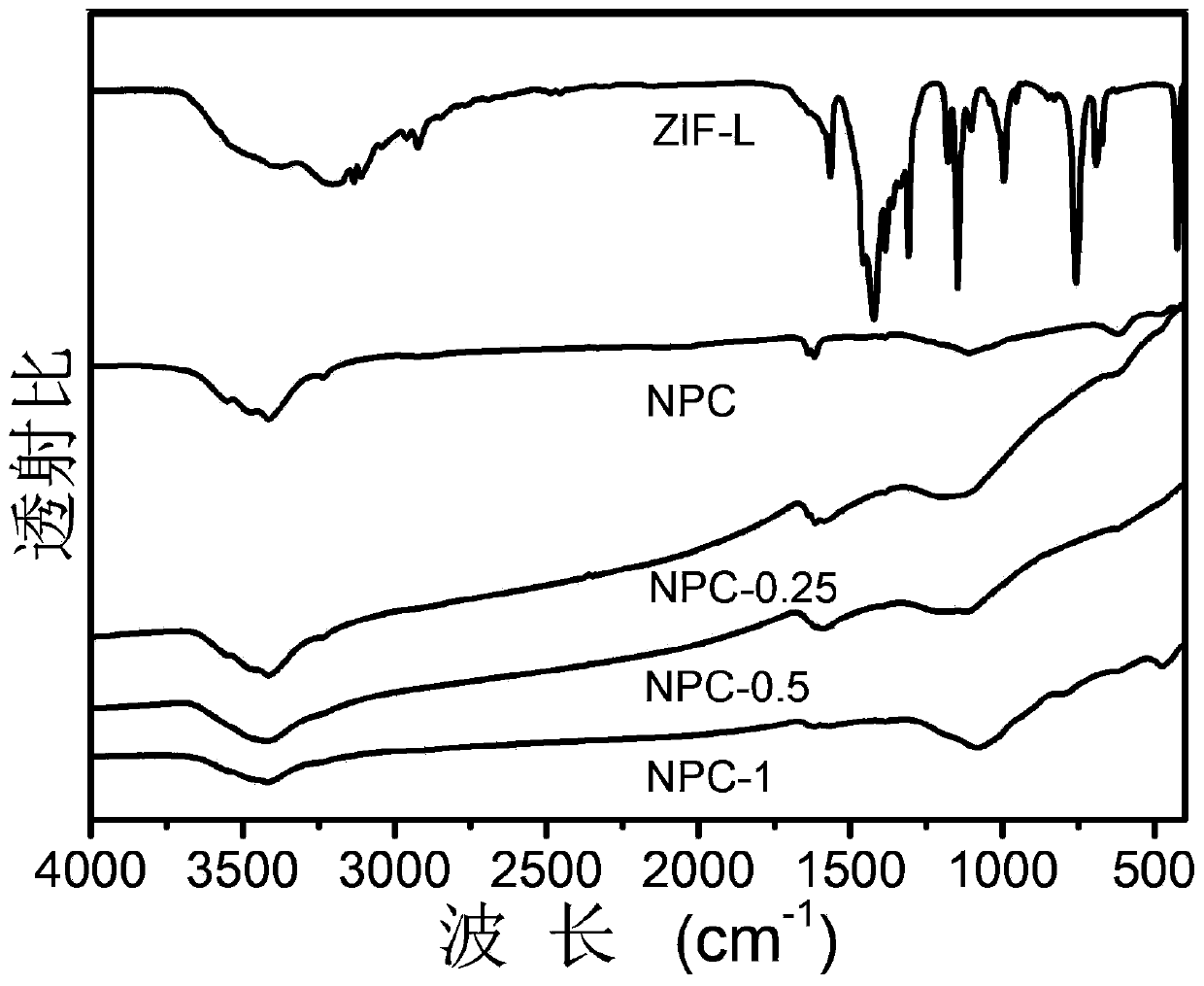

[0031] A nitrogen-doped porous carbon material derived from a two-dimensional zeolitic imidazole framework (ZIF-L).

[0032] The concentration of potassium hydroxide in this embodiment case is 0.5mol / L.

[0033] A method for preparing the nitrogen-doped porous carbon material of the above-mentioned embodiment, comprising the following steps:

[0034] (1) Dissolve zinc nitrate hexahydrate and di-methylimidazole in deionized water respectively, then slowly pour the zinc nitrate hexahydrate solution into the di-methylimidazole solution and stir for 4 hours (rotating speed is 150r / min), A white zeolitic imidazole framework (ZIF-L) was obtained. Wherein the molar ratio of zinc chloride hexahydrate, bis-methylimidazole and deionized water is 1:4:2264. The product obtained by stirring is centrifuged, washed and dried at a speed of 4000r / min; washed 3 to 5 times with deionized water; then vacuum-dried at 60°C for 10 hours to obtain a zeolite imidazole framework (ZIF-L).

[0035] (2...

Embodiment 2

[0038] A nitrogen-doped porous carbon material, prepared basically the same as the nitrogen-doped porous carbon material in Example 1, except that the concentration of potassium hydroxide in Example 2 is 0.25 mol / L.

[0039] The nitrogen-doped porous carbon material prepared in Example 2 is designated as NPC-0.25.

Embodiment 3

[0041] A nitrogen-doped porous carbon material, prepared basically the same as the nitrogen-doped porous carbon material in Example 1, except that the concentration of potassium hydroxide in Example 2 is 1 mol / L.

[0042] The nitrogen-doped porous carbon material prepared in Example 3 is designated as NPC-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com