Novel graphite refractory material plate and production process

A refractory material and production process technology, applied in the field of new graphite refractory board and production process, can solve the problems of short service life of refractory materials, poor thermal shock resistance, cracking, peeling, etc., achieve high cracking resistance and reduce heat Dissipation and low operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment discloses a novel graphite refractory plate and its production process, specifically as follows:

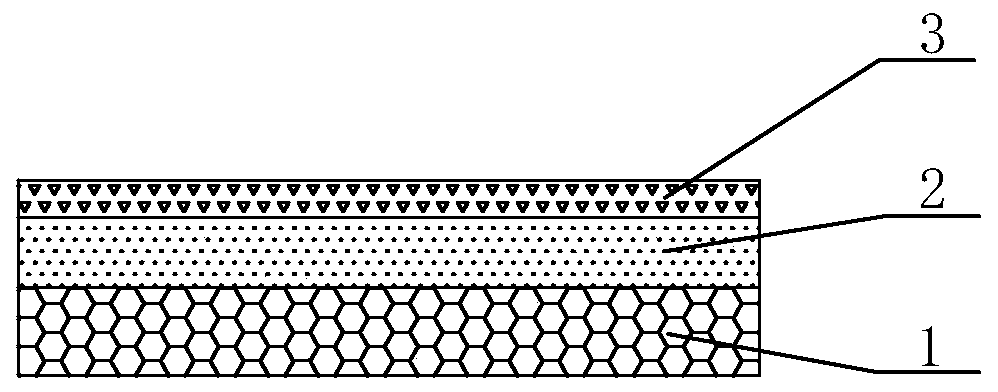

[0051] A new type of graphite refractory board, the refractory board is composed of a refractory layer, a thermal insulation layer and an adhesive layer combined together; the thickness ratio of the refractory layer, thermal insulation layer, and adhesive layer is 2:1:1;

[0052] The refractory layer is composed of the following materials in parts by weight:

[0053] 55 parts of graphite powder, 20 parts of clay, 2 parts of sodium chloride, 5 parts of calcium chloride, 5 parts of magnesium oxide, 20 parts of binder;

[0054] The insulation layer is made up of the following materials in parts by weight:

[0055] 10 parts of graphite powder, 30 parts of cement, 10 parts of fly ash, 1 part of foaming agent, 5 parts of glass fiber, 0.5 parts of silane coupling agent;

[0056] The bonding layer is made up of the following materials in parts by weight:

[0057...

Embodiment 2

[0068] This embodiment discloses a novel graphite refractory plate and its production process, specifically as follows:

[0069] A new type of graphite refractory board, the refractory board is composed of a refractory layer, a thermal insulation layer and an adhesive layer combined together; the thickness ratio of the refractory layer, thermal insulation layer, and adhesive layer is 2:1:1;

[0070] The refractory layer is composed of the following materials in parts by weight:

[0071] 65 parts of graphite powder, 35 parts of clay, 4 parts of sodium chloride, 10 parts of calcium chloride, 10 parts of magnesium oxide, 30 parts of binder;

[0072] The insulation layer is made up of the following materials in parts by weight:

[0073] 20 parts of graphite powder, 40 parts of cement, 20 parts of fly ash, 2 parts of foaming agent, 10 parts of glass fiber, 1 part of silane coupling agent;

[0074] The bonding layer is made up of the following materials in parts by weight:

[007...

Embodiment 3

[0087] This embodiment discloses a novel graphite refractory plate and its production process, specifically as follows:

[0088] A new type of graphite refractory board, the refractory board is composed of a refractory layer, a thermal insulation layer and an adhesive layer combined together; the thickness ratio of the refractory layer, thermal insulation layer, and adhesive layer is 2:1:1;

[0089] The refractory layer is composed of the following materials in parts by weight:

[0090] 60 parts of graphite powder, 27 parts of clay, 3 parts of sodium chloride, 7.5 parts of calcium chloride, 7.5 parts of magnesium oxide, 25 parts of binder;

[0091] The insulation layer is made up of the following materials in parts by weight:

[0092] 15 parts of graphite powder, 35 parts of cement, 15 parts of fly ash, 1.5 parts of foaming agent, 7.5 parts of glass fiber, 0.75 parts of silane coupling agent;

[0093] The bonding layer is made up of the following materials in parts by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com