A kind of inorganic pigment dyeing method of cotton textile

A technology for cotton textiles and inorganic pigments, applied in the field of textile printing and dyeing, can solve the problems of low rubbing fastness, low dyeing rate, long time consumption, etc., and achieve the effects of enhancing interfacial bonding force, improving easy agglomeration and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

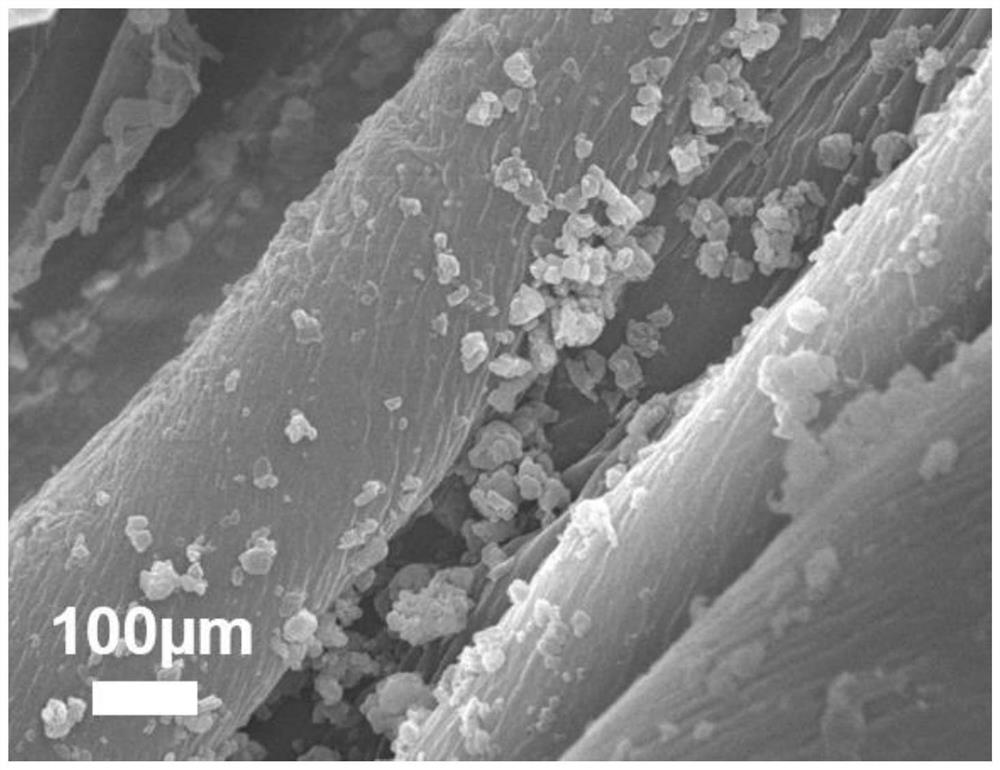

Image

Examples

Embodiment 1

[0046] A method for dyeing cotton textiles with inorganic pigments, comprising the steps of:

[0047] S1. Preprocessing:

[0048] S11. Preparation of washing solution: place the surfactant in the aqueous solution, mix it evenly and prepare the washing solution, wherein the concentration of the surfactant is 0.3g / L, and the stirring time is 25min;

[0049] S12, pretreatment of cotton fabrics: according to the bath ratio of 1:20, the cotton fabrics are placed in the washing liquid for washing treatment, and then dried to obtain the washed cotton fabrics, wherein the washing temperature is 60° C., and the washing time is 40 minutes. The drying temperature is 60°C, and the drying time is 40 minutes.

[0050] S2. Modification of inorganic pigment nanoparticles: Put 8g of cobalt blue nanoparticles into 80mL of acetone, stir for 5min, add 4mL of silane coupling agent KH570, stir for 12 hours, filter, wash with acetone for 5 times, and vacuum at 60°C Dry for 6 hours, take out and gr...

Embodiment 2-4

[0058] The difference from Example 1 is that in step S4, the setting of the dyeing temperature is different, and other steps are the same as in Example 1, and will not be repeated here.

[0059] Table 1 is the setting of the dyeing temperature and the performance parameters of the dyed cotton fabric in Examples 1-4

[0060] Example Dyeing temperature (℃) K / S value Example 1 200 6.6 Example 2 140 2.7 Example 3 180 4.5 Example 4 220 6.7

[0061] It can be seen from Table 1 that the higher the dyeing temperature of high boiling point solvent rapeseed oil, the higher the utilization rate of the dye and the larger the K / S value.

Embodiment 5-7

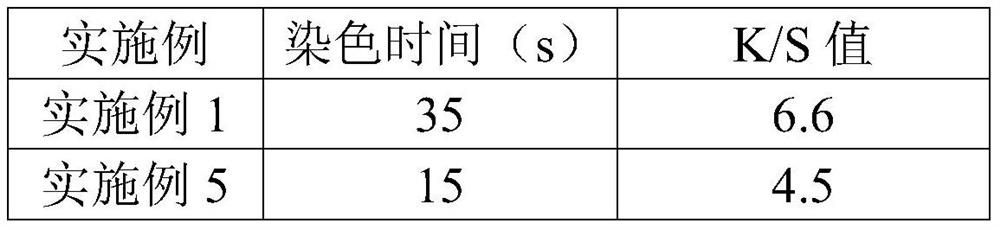

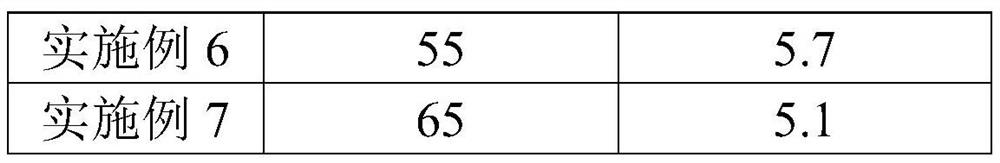

[0063] The difference from Embodiment 1 is that in step S4, the setting of the dyeing time is different, and other steps are the same as in Embodiment 1, and will not be repeated here.

[0064] Table 2 is the setting of dyeing time in embodiment 1 and embodiment 5-7 and the performance parameter of cotton fabric after dyeing

[0065]

[0066]

[0067] It can be seen from Table 2 that as the dyeing time increases, the K / S value presents a trend of first increasing and then decreasing. This is because when the modified cotton fabric is placed in a high-temperature oil bath for too long, the molecular structure of cellulose in the fiber will be destroyed to a certain extent, thereby affecting the dyeing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com