Application of hydrotalcite-like compound derived composite oxide material

A composite oxide and hydrotalcite technology, which is applied in the field of acid gas treatment and resource recovery, can solve the problem of low activity and achieve excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

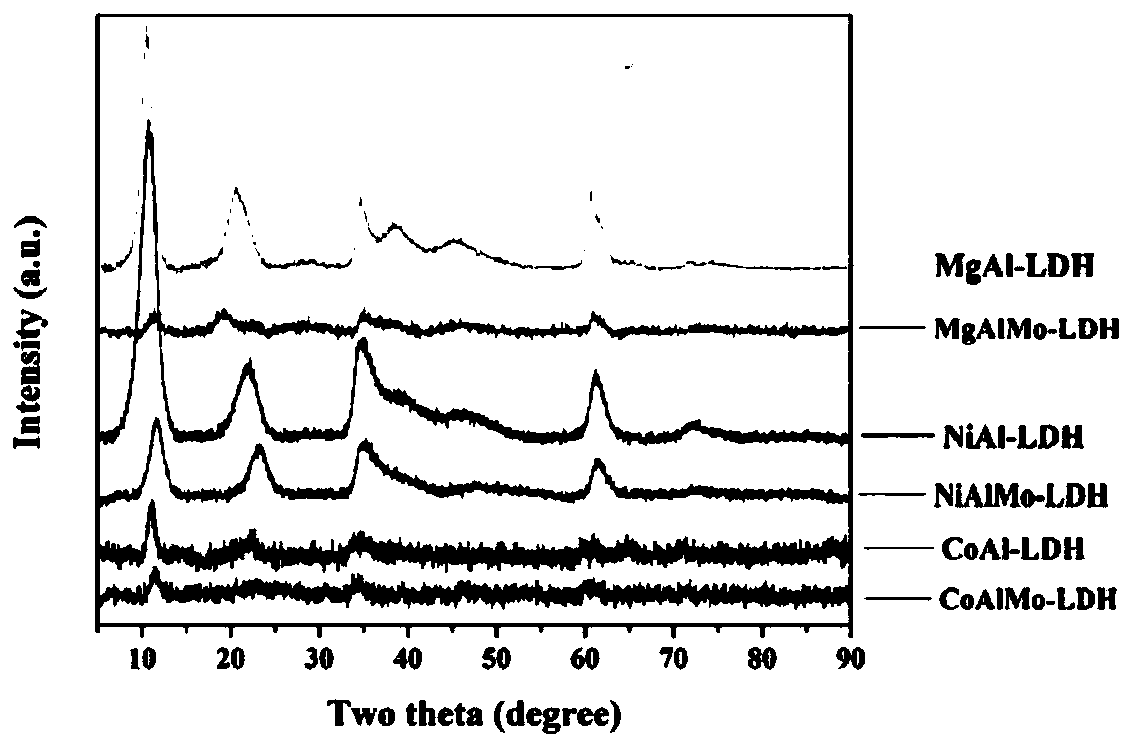

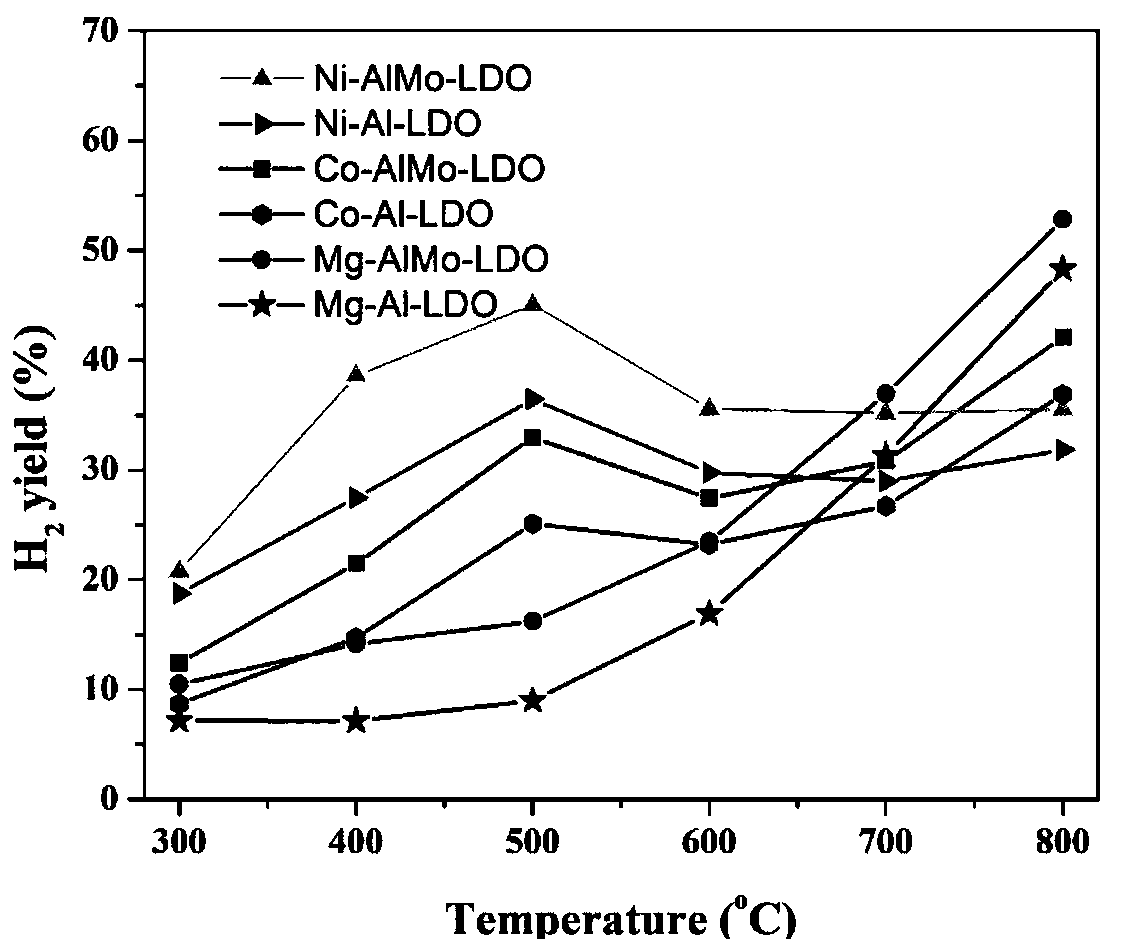

[0036] Mg 3 -Al-LDO, Co 3 -Al-LDO and Ni 3 -Synthesis method of Al-LDO hydrotalcite-derived composite oxide:

[0037] MgNO 3 , CoNO 3 , NiNO 3 , Al 2 (NO 3 ) 3 , NaOH and (NH 4 ) 6 Mo 7 O 24 As a raw material for synthesis. First, 60mmol of MgNO 3 (CoNO 3 , NiNO 3 ), 20mmol of Al 2 (NO 3 ) 3 Dissolve the solution 1 in 200ml of deionized water from which carbon dioxide has been removed with nitrogen in advance, and pour the mixed solution 1 into 800ml of 0.15M NaOH solution in a short time (5s). It was then stirred for 15 minutes under a nitrogen atmosphere. Then suction filter, wash 3 times with deionized water for removing carbon, and dry the filter cake overnight at 80℃ to make M 2 Al-LDH precursor. The precursor is calcined at 550℃ in air for 4h to obtain the hydrotalcite-like composite oxide Mg 3 Al-LDO, Co 3 Al-LDO and Ni 3 Al-LDO.

[0038] Mg 3 AlMo-LDO, Co 3 AlMo-LDO and Ni 3 Synthesis method of AlMo-LDO hydrotalcite-derived composite oxide:

[0039] 3 g of the milled 40-60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com