Material and method for preparing holographic color patterns and application of holographic color patterns

A color pattern and color image technology, which is applied to information-carrying cards, printing, instruments, etc., can solve the problems of opaque materials and low substrate selectivity, and achieve the effect of broad application prospects, bright colors, and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. A material capable of preparing holographic color patterns, which is formed by grafting a photosensitive group and a polymer, wherein the photosensitive group has a structural formula (IV):

[0056]

[0057] The polymer is polyamic acid.

[0058] Its specific preparation process is as follows:

[0059]

[0060] Add 4,4'-biphenylenediamine (18.4 grams) and photosensitive structure-containing biphenylenediamine (111 grams) to the equipment equipped with mechanical stirring and inert gas protection device, add anhydrous N-methyl Pyrrolidone (1556 grams) was stirred and dissolved at 0-25 degrees, and then pyromellitic anhydride (43.6 grams) was added to the above-mentioned materials at one time, and the stirring reaction was continued for 24 hours. After the reaction, a photosensitive polyamic acid solution was obtained. After separation, a photosensitive polyamic acid is obtained.

[0061] Wherein, the range of x:y is between 10:1 and 100:1.

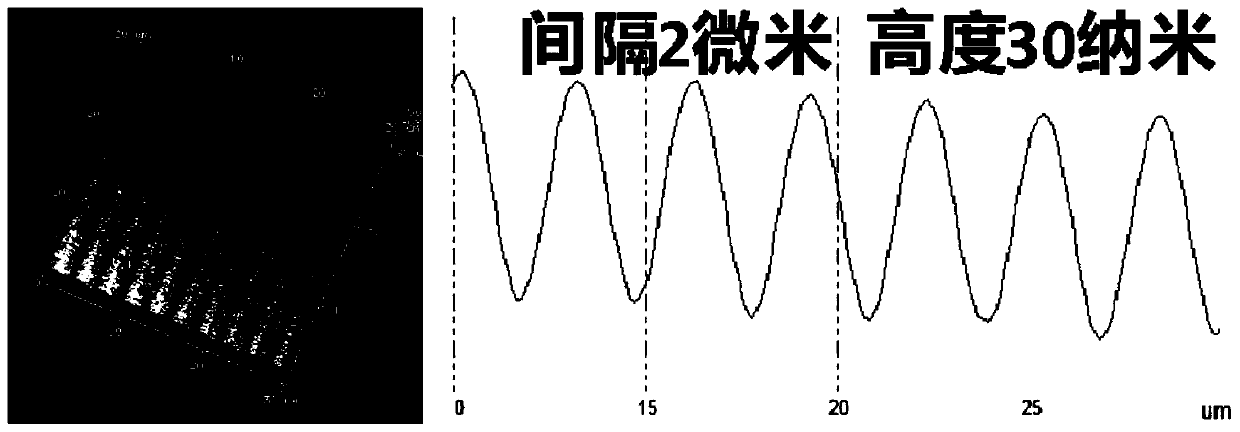

[0062] The photos...

Embodiment 2

[0069] A material capable of preparing holographic color patterns, which is formed by grafting a photosensitive group and a polymer, wherein the photosensitive group has a structural formula (VI):

[0070]

[0071] The polymer is polyamic acid, and the preparation method is the same as in Example 1.

[0072] Wherein, x:y is 10:1.

[0073] The photosensitive group accounts for 2%-15% of the mass fraction of the photosensitive polyamic acid.

[0074] With the photosensitive polyamic acid of above-mentioned preparation as photosensitive coating, adopt the flow process in the embodiment 1 to prepare the holographic color image, can obtain the material of the holographic color pattern that is lighter than the background color of the film of embodiment 1, more transparent ( image 3 ). The reason is that the intrinsic light absorption of the structural formula (VI) is not in the visible region.

Embodiment 3

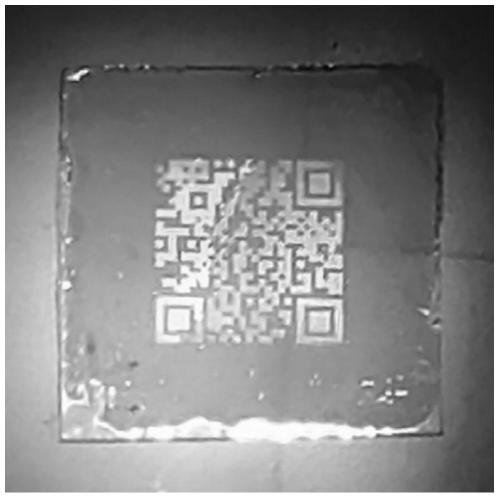

[0076] The photosensitive polyamic acid prepared in Example 1 was used as a photosensitive coating to prepare a holographic color image. The preparation process was the same as in Example 1, except that the obtained photosensitive polyamic acid solution was evenly cast after being filtered and defoamed. On the clean glass, after the solvent was evaporated at 90 degrees for 5 hours, it was peeled off, and a photolithography machine was used to carry out ultraviolet light engraving to construct patterns, and the film after photolithography was immersed in an ethanol solution containing copper chloride (10g / L). Adsorption, soaking time 15 seconds, take it out, rinse with absolute ethanol, and dry to get Figure 4 The self-supporting transparent holographic patterned film shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com