High-temperature-resistant stable protective film material and preparation method thereof

A stable and protective film technology, which is applied in the field of high-temperature-resistant and stable protective film materials and its preparation, can solve the problems of poor high-temperature resistance of protective films, etc., and achieve the effects of good water resistance, enhanced heat resistance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

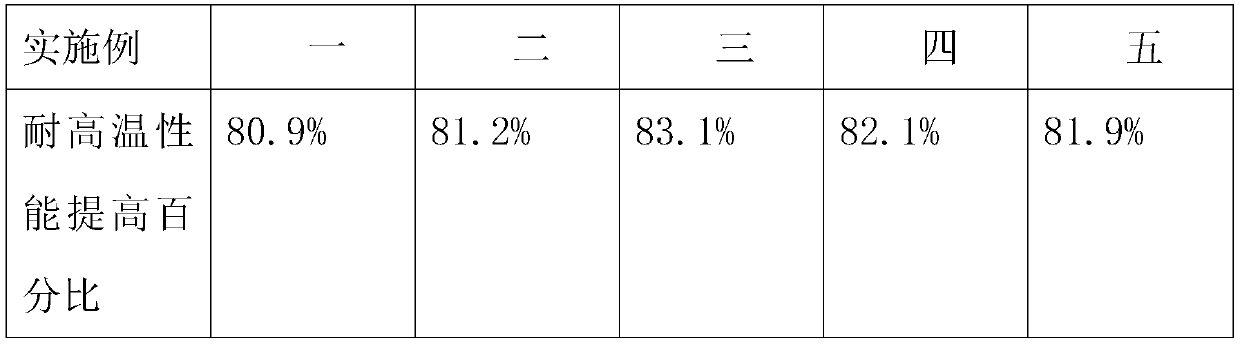

Examples

Embodiment 1

[0041] A high temperature resistant and stable protective film material, comprising the following raw materials in parts by weight: 30 parts of polyethylene, 15 parts of calcium carbonate, 7 parts of plasticizer, 10 parts of polyvinyl chloride resin, 10 parts of epoxy resin, nano silicon dioxide 2 parts, 1 part of antioxidant, 5 parts of polytetrafluoroethylene, 5 parts of acrylamide, 2 parts of magnesium stearate, 1 part of polyurethane, 10 parts of polyether imine, 5 parts of polyolefin, 1 part of heat stabilizer, 2 parts of polyester fiber, 1 part of anti-scratch agent, 1 part of wear-resistant agent;

[0042] Its preparation method comprises the following steps:

[0043] S1: Polyethylene, calcium carbonate, plasticizer, nano-silica, antioxidant, polytetrafluoroethylene, polyetherimide, polyolefin, heat stabilizer, polyester fiber, anti-scratch agent, wear-resistant Put the agent into the mixing equipment, heat and stir and mix to prepare the mixture, the stirring speed is...

Embodiment 2

[0048] A high temperature resistant and stable protective film material, comprising the following raw materials in parts by weight: 34 parts of polyethylene, 16 parts of calcium carbonate, 8 parts of plasticizer, 11 parts of polyvinyl chloride resin, 11 parts of epoxy resin, nano silicon dioxide 3 parts, 2 parts of antioxidant, 6 parts of polytetrafluoroethylene, 6 parts of acrylamide, 3 parts of magnesium stearate, 2 parts of polyurethane, 11 parts of polyether imine, 6 parts of polyolefin, 2 parts of heat stabilizer, 3 parts of polyester fiber, 2 parts of anti-scratch agent, 2 parts of wear-resistant agent;

[0049] Its preparation method comprises the following steps:

[0050] S1: Polyethylene, calcium carbonate, plasticizer, nano-silica, antioxidant, polytetrafluoroethylene, polyetherimide, polyolefin, heat stabilizer, polyester fiber, anti-scratch agent, wear-resistant Put the agent into the mixing equipment, heat and stir and mix to prepare the mixture, the stirring spe...

Embodiment 3

[0055] A high temperature resistant and stable protective film material, comprising the following raw materials in parts by weight: 40 parts of polyethylene, 17 parts of calcium carbonate, 9 parts of plasticizer, 12 parts of polyvinyl chloride resin, 12 parts of epoxy resin, nano silicon dioxide 4 parts, 3 parts of antioxidant, 7 parts of polytetrafluoroethylene, 7 parts of acrylamide, 4 parts of magnesium stearate, 3 parts of polyurethane, 12 parts of polyether imine, 7 parts of polyolefin, 3 parts of heat stabilizer, 4 parts of polyester fiber, 3 parts of anti-scratch agent, 3 parts of wear-resistant agent;

[0056] Its preparation method comprises the following steps:

[0057] S1: Polyethylene, calcium carbonate, plasticizer, nano-silica, antioxidant, polytetrafluoroethylene, polyetherimide, polyolefin, heat stabilizer, polyester fiber, anti-scratch agent, wear-resistant Put the agent into the mixing equipment, heat and stir and mix to prepare the mixture, the stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com