2D/2D heterojunction pressure-photocatalyst and preparation method thereof

A photocatalyst and heterojunction technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve unsatisfactory photocatalytic activity, hinder the industrial application of photocatalysts, and photocatalytic efficiency Low and other problems, to achieve the effect of efficient utilization, effective separation, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

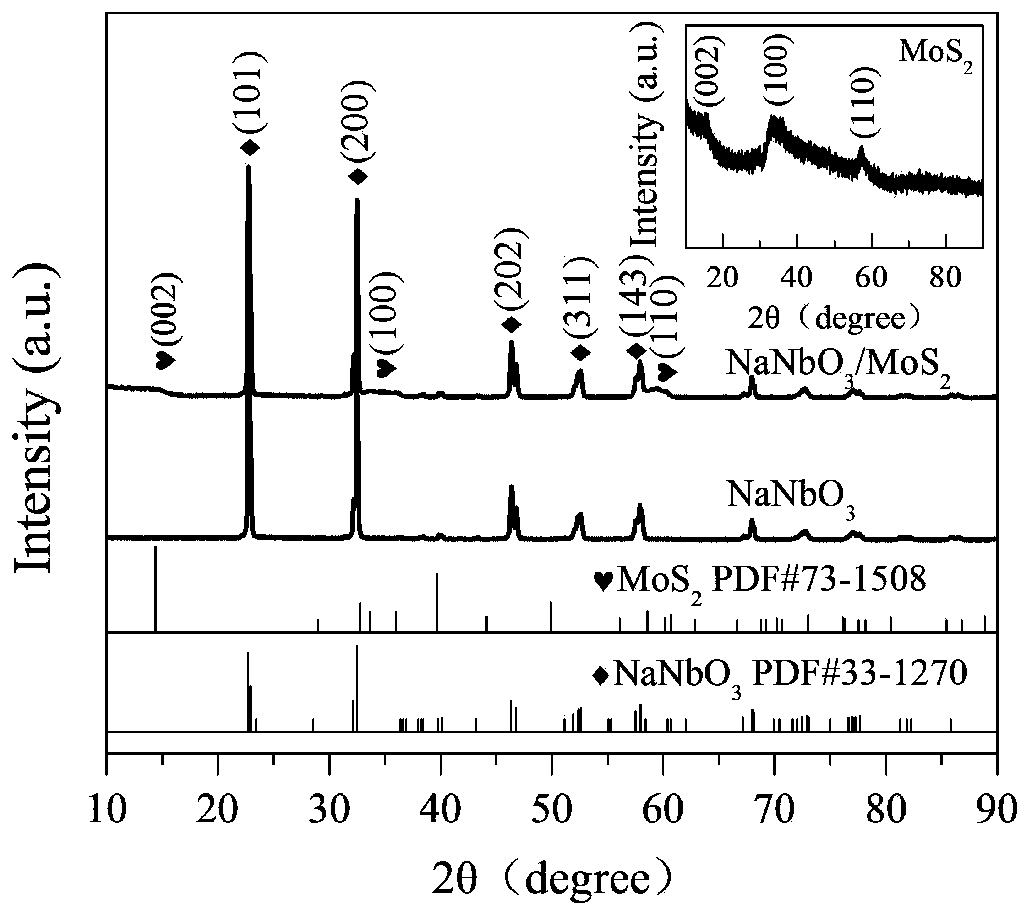

[0028] 1) Weigh 0.5g of Nb 2 o 5 and 0.02g of sodium dodecylbenzenesulfonate dispersed in 80ml of KOH and NaOH with K + :Na + = Mineralizer solution (0.5mol / L) with a ratio of 2:1, stirred for 1h, transferred the above material to a Teflon stainless steel autoclave (100ml), and then heated at 200°C for 10h. After cooling, the white precipitate was washed with deionized water, and then dried at 80 °C to obtain NaNbO 3 Nanosheets.

[0029] 2) Weigh 0.065g of sodium molybdate and 0.130g of thiourea and dissolve them in 20mL of oxalic acid solution (0.075mol / L), stir magnetically for 0.5h, and dissolve the total mass of 10% NaNbO 3 Nanosheet powder was added to the above solution, stirred for 1h, then transferred to a 100ml Teflon autoclave, and heated at 200°C for 24h. Cool to room temperature, wash several times with deionized water, and then dry at 60°C for 12h to obtain the NaNbO 3 / MoS 2 piezoelectric catalyst.

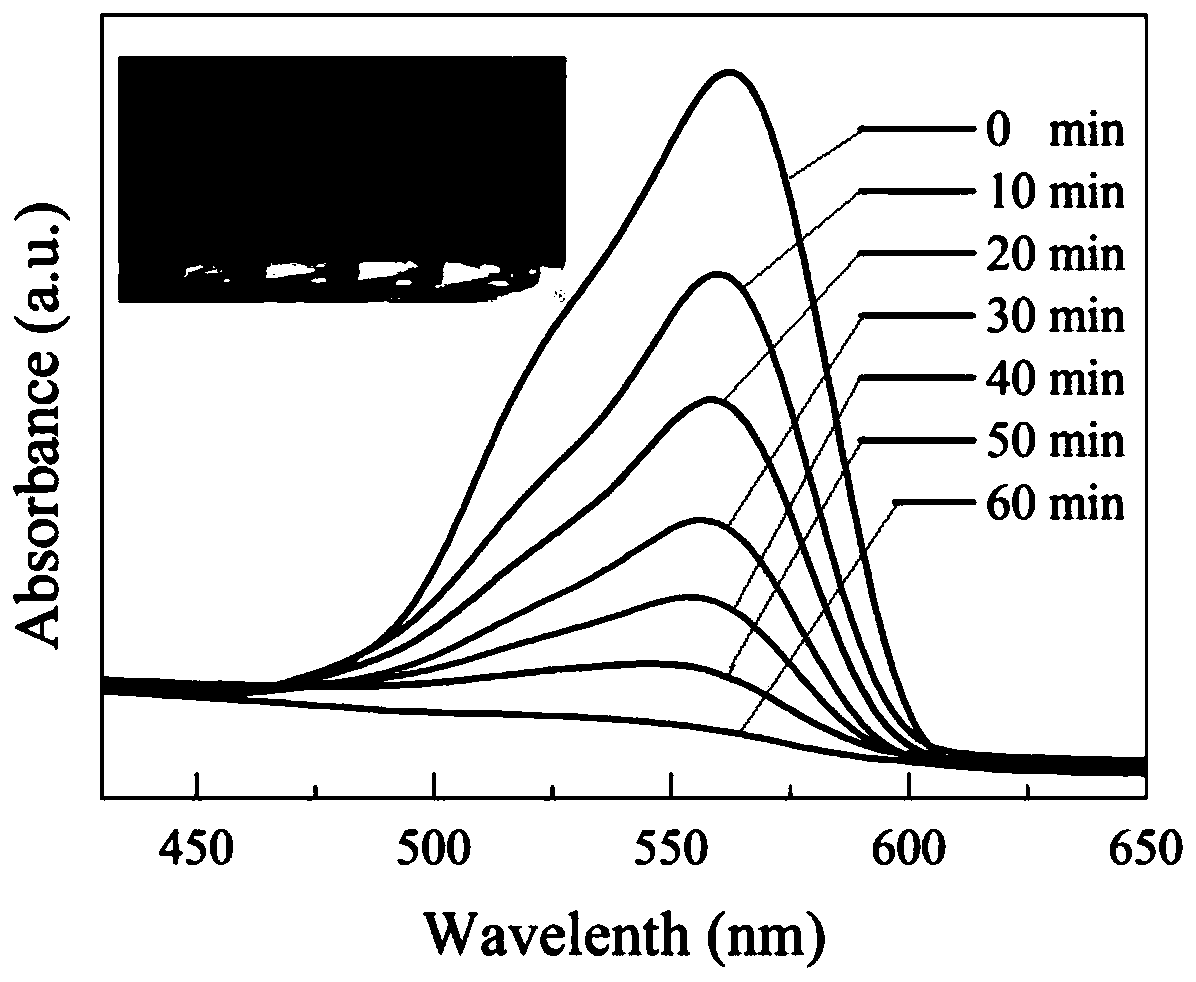

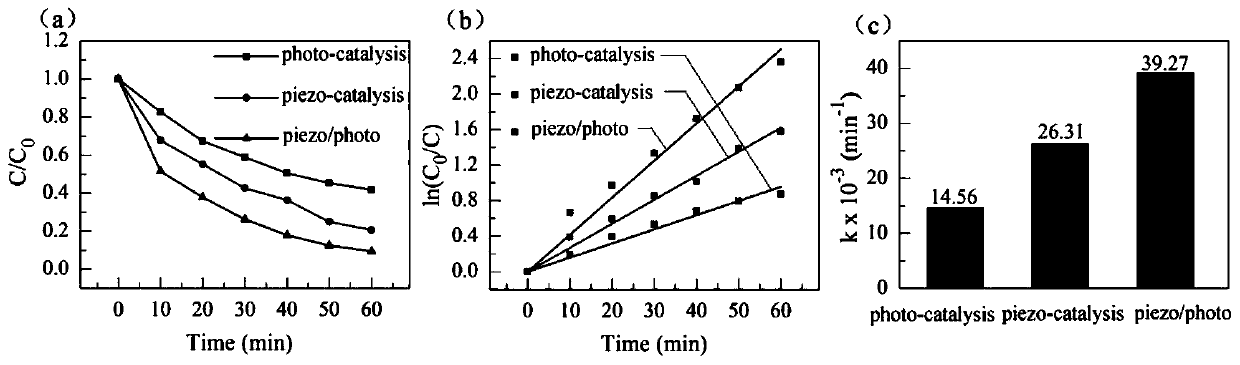

[0030] 3) Use a catalyst concentration of 0.05 mg / L to ...

Embodiment 2

[0032] 1) Weigh 0.5g of Nb 2 o 5 and 0.02g of sodium dodecylbenzenesulfonate dispersed in 80ml of KOH and NaOH with K + :Na += Mineralizer solution (0.5mol / L) with a ratio of 2:1, stirred for 1h, transferred the above material to a Teflon stainless steel autoclave (100ml), and then heated at 200°C for 10h. After cooling, the white precipitate was washed with deionized water, and then dried at 80 °C to obtain NaNbO 3 Nanosheets.

[0033] 2) Weigh 0.065g of sodium molybdate and 0.130g of thiourea and dissolve them in 20mL of oxalic acid solution (0.075mol / L), stir magnetically for 1h, and dissolve the total mass of 10% NaNbO 3 The nanosheet powder was added to the above solution, stirred for 1 h, then transferred to a 100 ml Teflon autoclave, and heated at 200 °C for 24 h. Cool to room temperature, wash several times with deionized water, and then dry at 60°C for 12h to obtain the NaNbO 3 / MoS 2 piezoelectric catalyst.

[0034] 3) Use a catalyst concentration of 0.1 mg / L...

Embodiment 3

[0036] 1) Weigh 0.5g of Nb 2 o 5 and 0.02g of sodium dodecylbenzenesulfonate dispersed in 80ml of KOH and NaOH with K + :Na + =2:1 mineralizer solution (0.5mol / L), stirred for 1h, transferred the above material to a Teflon stainless steel autoclave (100ml), and then heated at 210°C for 6h. After cooling, the white precipitate was washed with deionized water, and then dried at 80 °C to obtain NaNbO 3 Nanosheets.

[0037] 2) Weigh 0.065g of sodium molybdate and 0.130g of thiourea and dissolve them in 20mL of oxalic acid solution (0.075mol / L), stir for 1h by magnetic force, add NaNbO3 nanosheet powder with a total mass of 40% to the above solution, and stir for 1h , and then transferred to a 100ml Teflon autoclave and heated at 200°C for 24h. Cool to room temperature, wash several times with deionized water, and then dry at 60°C for 12h to obtain the NaNbO 3 / MoS 2 piezoelectric catalyst.

[0038] 3) Use a catalyst concentration of 0.1mg / L to achieve piezoelectric-photoco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com