High-temperature 500-degrees centigrade abrasion-resistant brake pad and preparation method thereof

A technology of brake pads and wear-resistant type, which is applied in the field of high-temperature 500-degree wear-resistant brake pads and its preparation, can solve the problems of reduced friction coefficient of brake pad materials, increase of friction material temperature, and increased wear of brake pads, etc., to achieve Low wear at medium and high temperatures, stable friction coefficient, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

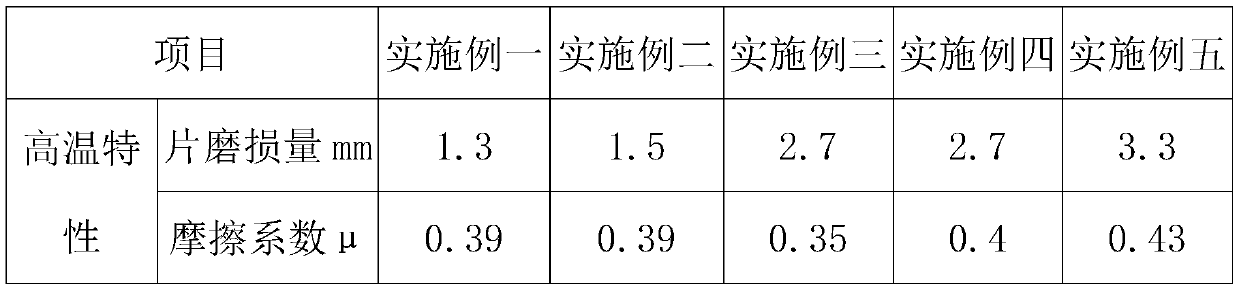

Examples

Embodiment 1

[0028] This embodiment proposes a brake pad without adding potassium titanate lamellae and steel wool, and includes the following raw materials in parts by weight: 15% of scaly potassium lithium titanate, 10% of zirconia, 8% of resin, 5% of copper fiber, mineral Fiber 4%, friction powder 4%, rubber powder 3%, aramid fiber 5%, tin sulfide 5%, graphite 3%, coke 4%, calcium hydroxide 5%, mica powder 3%, the balance is barium sulfate, total 100%;

[0029] Its preparation method comprises the following steps:

[0030] S1. Mixing of raw materials: Prepare the scale-like potassium lithium titanate, resin, copper fiber, mineral fiber, aramid fiber, and barium sulfate in the above parts by weight and pour them into the mixer for uniform mixing. Mix at a speed of 2000r / min for 15min , and then pour the remaining raw materials into the mixer to mix evenly, and mix for 15 minutes to obtain the mixture A;

[0031] S2. Pressing: put the mixture A into the hot press, press it with the clea...

Embodiment 2

[0035] This embodiment proposes a brake pad, without adding scale-like potassium lithium titanate and steel wool, adding potassium titanate lamellae, including the following raw materials in parts by weight: 15% potassium titanate lamellae, 10% zirconia, and 8% resin , copper fiber 5%, mineral fiber 4%, friction powder 4%, rubber powder 3%, aramid fiber 5%, tin sulfide 5%, graphite 3%, coke 4%, calcium hydroxide 5%, mica powder 3%, The balance is barium sulfate, totaling 100%;

[0036] Its preparation method comprises the following steps:

[0037] S1. Mixing of raw materials: Prepare the scale-like potassium lithium titanate, resin, copper fiber, mineral fiber, aramid fiber, and barium sulfate in the above parts by weight and pour them into the mixer for uniform mixing. Mix at a speed of 2000r / min for 15min , and then pour the remaining raw materials into the mixer to mix evenly, and mix for 15 minutes to obtain the mixture A;

[0038] S2. Pressing: put the mixture A into th...

Embodiment 3

[0042] This embodiment proposes a brake pad, does not add potassium titanate lamellae, steel wool, increases the proportion of scale-like potassium titanate lithium, and other raw materials and proportions remain unchanged, which includes the following raw materials in parts by weight: scale-like potassium titanate Lithium 30%, zirconia 10%, resin 8%, copper fiber 5%, mineral fiber 4%, friction powder 4%, rubber powder 3%, aramid fiber 5%, tin sulfide 5%, graphite 3%, coke 4% , calcium hydroxide 5%, mica powder 3%, the balance is barium sulfate, the total is 100%;

[0043] Its preparation method comprises the following steps:

[0044] S1. Mixing of raw materials: Prepare the scale-like potassium lithium titanate, resin, copper fiber, mineral fiber, aramid fiber, and barium sulfate in the above parts by weight and pour them into the mixer for uniform mixing. Mix at a speed of 2000r / min for 15min , and then pour the remaining raw materials into the mixer to mix evenly, and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com