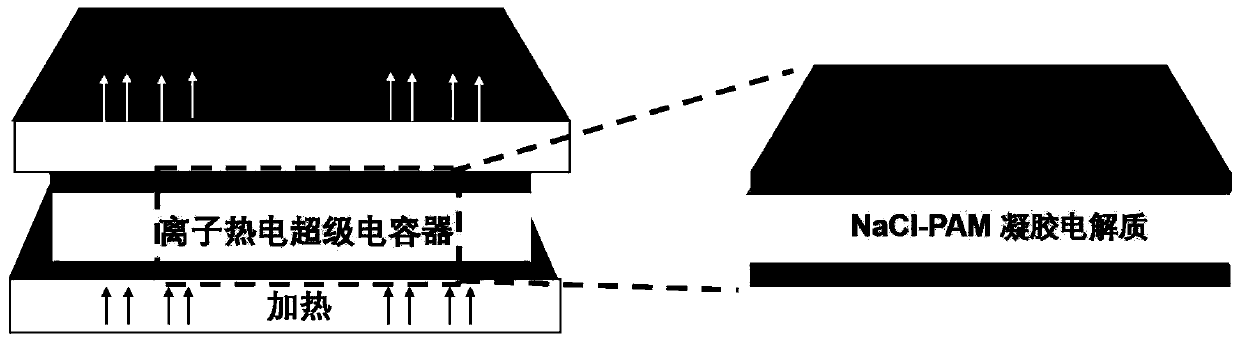

Gel electrode, full-gel-state ion thermoelectric supercapacitor and preparation of full-gel-state ion thermoelectric supercapacitor

A technology for supercapacitors and electrodes, which is applied in the field of gel electrodes and all-gel ion thermoelectric supercapacitors and their preparation, can solve the problems of poor flexibility and unfriendly environment of ion thermoelectric supercapacitors, and achieve environmental friendliness and good application prospects , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

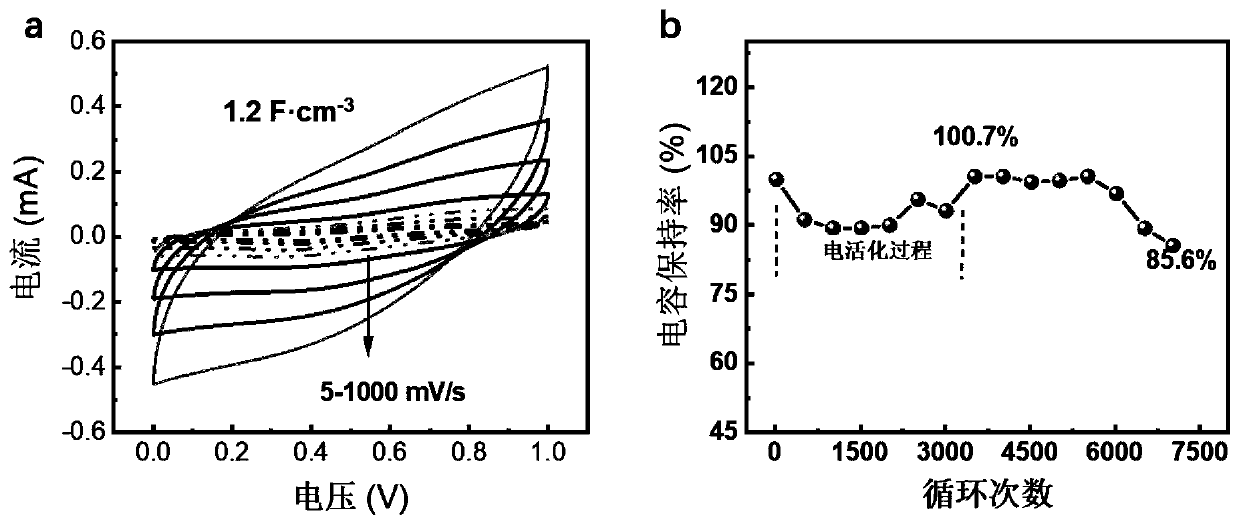

Examples

Embodiment 1

[0042] (1) Disperse 50 mg of carbon nanotubes in 10 ml of ultrapure water, and sonicate for 1 hour to obtain a carbon nanotube dispersion;

[0043] (2) Add 1000 mg of acrylamide monomer, 10 mg of ammonium persulfate, and 1 mg of N,N-methylenebisacrylamide to the above carbon nanotube dispersion, and stir for 10 minutes;

[0044] (3) Transfer the above dispersion to an oven, heat and cure at 60°C for 30 minutes to obtain a CNTs / PAM hybrid gel electrode;

[0045] (4) 3.6g NaCl is dissolved in the saturated NaCl solution that 10ml ultrapure water makes;

[0046] (5) Add 1000 mg of acrylamide monomer, 10 mg of ammonium persulfate, and 1 mg of N,N-methylenebisacrylamide to the above saturated NaCl solution, and stir for 10 minutes;

[0047] (6) Transfer the above dispersion to an oven, heat and cure at a temperature of 60° C. for 30 minutes to obtain NaCl-PAM gel electrolyte;

[0048] (7) Soak the CNTs / PAM gel electrode in saturated NaCl solution for 12 hours, take it out and dry...

Embodiment 2

[0052] (1) Disperse 80 mg of carbon nanotubes in 10 ml of ultrapure water, and sonicate for 1.5 hours to obtain a carbon nanotube dispersion;

[0053] (2) Add 1500 mg of acrylamide monomer, 30 mg of ammonium persulfate, and 2 mg of N,N-methylenebisacrylamide to the above carbon nanotube dispersion, and stir for 20 minutes;

[0054] (3) Transfer the above dispersion to an oven, heat and cure at 70°C for 60 minutes to obtain a CNTs / PAM hybrid gel electrode;

[0055] (4) 3.6g NaCl is dissolved in the saturated NaCl solution that 10ml ultrapure water makes;

[0056] (5) Add 1500 mg of acrylamide monomer, 30 mg of ammonium persulfate, and 2 mg of N,N-methylenebisacrylamide to the above saturated NaCl solution, and stir for 20 minutes;

[0057] (6) Transfer the above dispersion to an oven, heat and cure at a temperature of 70° C. for 60 minutes to obtain NaCl-PAM gel electrolyte;

[0058] (7) Soak the CNTs / PAM gel electrode in saturated NaCl solution for 18 hours, take it out and ...

Embodiment 3

[0064] (1) Disperse 100mg of carbon nanotubes in 10ml of ultra-pure water, and ultrasonicate for 2 hours to obtain a carbon nanotube dispersion;

[0065] (2) Add 2000 mg of acrylamide monomer, 60 mg of ammonium persulfate, and 3 mg of N, N-methylenebisacrylamide to the above carbon nanotube dispersion, and stir for 30 minutes;

[0066] (3) Transfer the above dispersion to an oven, heat and cure at 80°C for 90 minutes to obtain a CNTs / PAM hybrid gel electrode;

[0067] (4) 3.6g NaCl is dissolved in the saturated NaCl solution that 10ml ultrapure water makes;

[0068] (5) Add 2000 mg of acrylamide monomer, 60 mg of ammonium persulfate, and 3 mg of N,N-methylenebisacrylamide to the above saturated NaCl solution, and stir for 30 minutes;

[0069] (6) Transfer the above dispersion to an oven, heat and cure at 80°C for 90 minutes to obtain NaCl-PAM gel electrolyte;

[0070] (7) Soak the CNTs / PAM gel electrode in a saturated NaCl solution for 24 hours, take it out and dry it for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com