Method for producing polyamide comprising amide-based molecular weight modifier, and polyamide produced thereby

A technology of molecular weight modifier and polyamide, which is applied in the field of polyamide, can solve the problems of low efficiency, achieve the effects of preventing molecular weight increase, shortening polymerization time, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

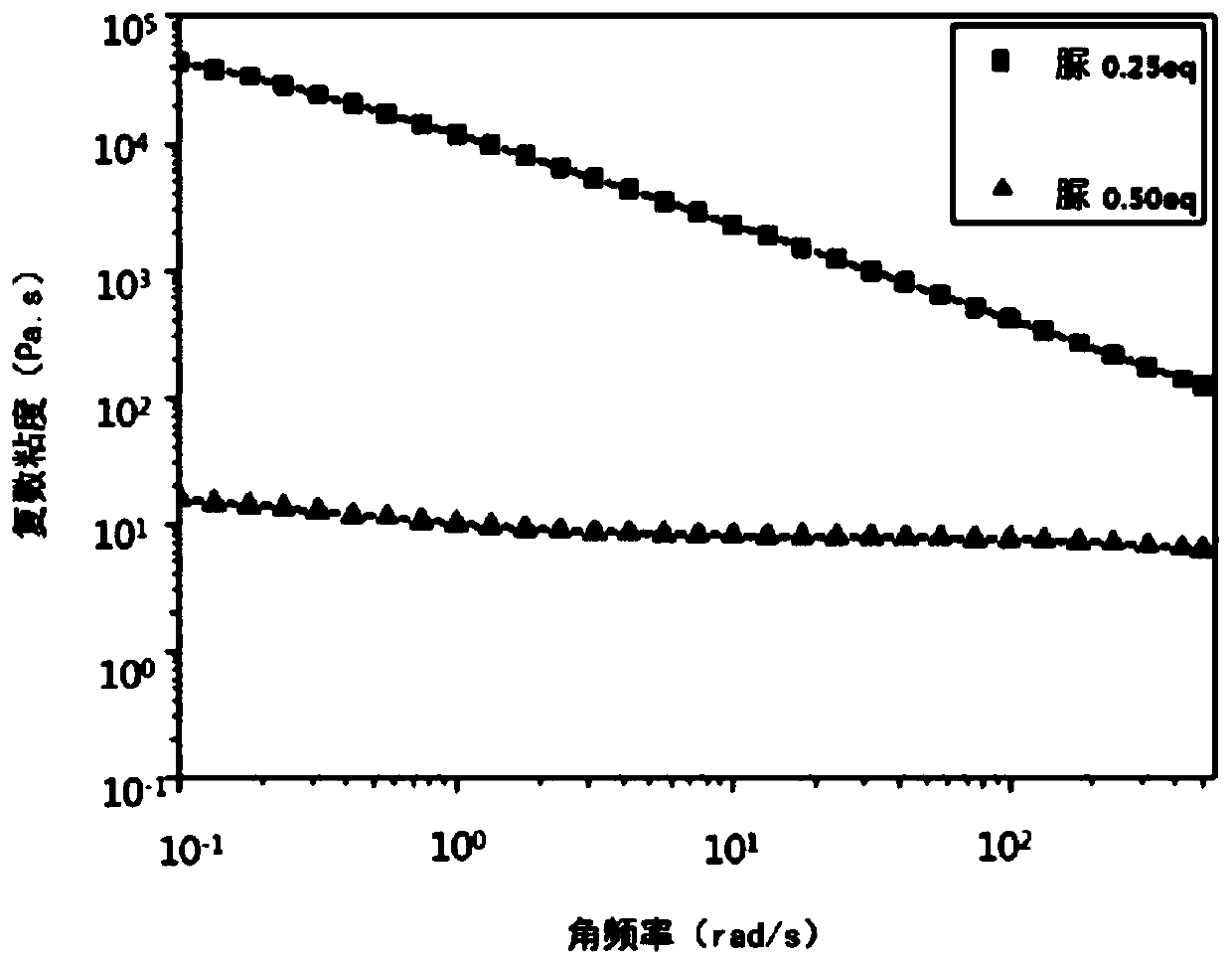

[0063] In this regard, in the present invention, a polyamide preparation method including an amide molecular weight regulator is provided, and the polyamide is prepared by anionic polymerization, which includes: a lactam; relative to the total amount of 100 parts by weight of the lactam, The alkali metal as an initiator is 0.01 to 20 parts by weight, the amide compound represented by the following chemical formula 1 as a molecular weight modifier is 0.3 to 10 parts by weight, and the activator is 0.002 to 7.0 parts by weight. In this way, a solution to the above-mentioned problems is sought.

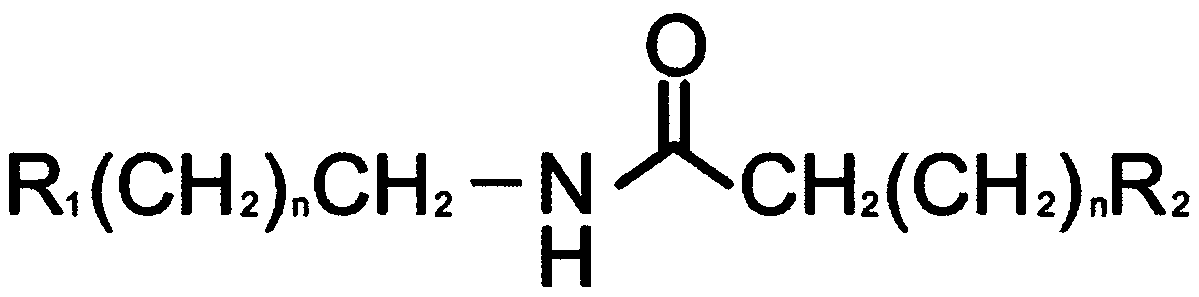

[0064] Chemical formula 1:

[0065]

[0066] The R 1 and R 2 may be the same or different from each other, and are substituents containing heteroatoms, or hydrogen, straight-chain or branched-chain alkyl groups with 1 to 10 carbon atoms, straight-chain or branched-chain alkenyl groups with 2 to 10 carbon atoms, Aryl group having 6 to 20 carbon atoms, alkaryl group having 7 to 21 ca...

Embodiment 1

[0109] Preparation of Polymerized Samples Using Acetanilide as Molecular Weight Regulator

[0110] For the flask kept at 60°C under vacuum in order to remove the moisture in the flask, after the vacuum was released, 20g of laurolactam, 0.14g of acetanilide, and 0.02g of NaH were added, and the temperature was raised to 160°C in a vacuum atmosphere. ℃. After that, the reaction temperature was set at 230° C., nitrogen gas was injected, and after hydrogen gas generated while the substance was melted was removed, 3.4 ml of carbon dioxide was injected to react for 30 minutes. Finally, 30 minutes later, an aqueous formic acid solution (formic acid: distilled water = 1:1) was poured into the flask to terminate the reaction, and a sample having a content based on Table 1 below was collected. The molecular weight and molecular weight distribution index (PDI: polydispersity index) were confirmed using this, and the result is shown in Table 2 below.

[0111] Table 1:

[0112] ...

Embodiment 2

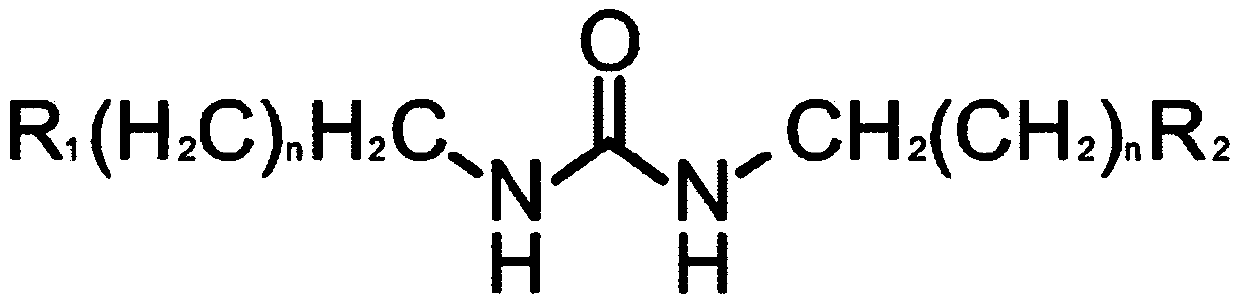

[0114] Preparation of Polymerized Samples Using Urea as Molecular Weight Regulator

[0115] The reaction was performed in the same manner as in Example 1 except that 0.12 g of urea (Urea) was used as a molecular weight regulator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com