Preparation method of photocatalytic material for efficiently degrading methylene blue dye in wastewater

A technology of methylene blue dye and photocatalytic material, which is applied in the field of photocatalytic material preparation, can solve the problems of difficulty in controlling the morphology of graphitic carbon nitride, narrow light absorption range, small specific surface area, etc. The effect of good performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

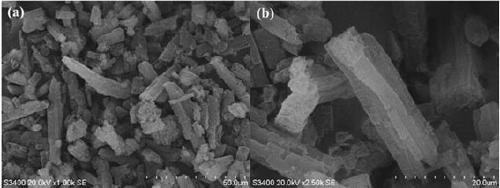

Image

Examples

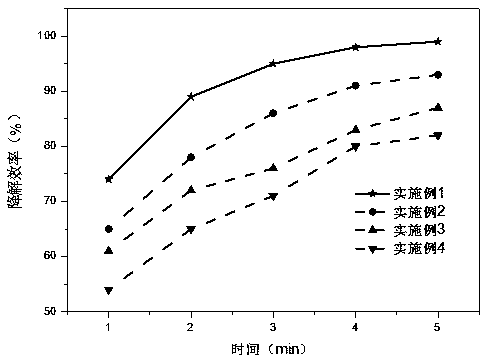

Embodiment 1

[0025] Example 1: Preparation and application of a photocatalytic material for efficiently degrading methylene blue dye in wastewater

[0026] (1) Accurately weigh 0.63 g of melamine and 0.64 g of cyanuric acid and place them in 500 mL clean beakers respectively, add 200 mL of secondary water to each, stir magnetically for 30 min, and set the temperature at 60°C to obtain clear melamine and cyanuric acid solution;

[0027] (2) Keep the temperature at 60°C, quickly mix the cyanuric acid solution with the melamine solution, continue magnetic stirring for 2 h, and form a white precipitate of supramolecular self-assembly, after standing still, centrifuge to remove the secondary water, and place the white precipitate at 80 Dry at ℃ for 12 h;

[0028] (3) Weigh 1 g of the above white solid into a crucible and place it in a muffle furnace for high-temperature calcination. The program is set to rise to 550 °C at a rate of 10 °C / min, keep the temperature for 4 h, and cool the calcined...

Embodiment 2

[0033] (1) Collect the reaction solution after the degradation treatment in Example 1, centrifuge to remove the liquid, and the carbon nitride solid in the graphite phase is washed and separated by secondary water and ethanol, dried at 80°C for 12 h, and cooled to room temperature Put the reclaimed graphite phase carbon nitride into a mortar and grind for 30 min to obtain powdered graphite phase carbon nitride;

[0034] (2) Take 150 mL of wastewater containing 10 mg / L methylene blue dye and place it in a photodegradation quartz reactor, add 150 mg of recovered graphite phase carbon nitride, and stir for 30 min in the dark to make graphite phase carbon nitride and methylene blue The dye is fully functional; 2 mL of the reaction solution is filtered through a 0.22 μm needle filter, and the filtrate is stored in a labeled brown centrifuge tube. After turning on the circulating cooling water, continue stirring to keep the temperature of the reaction solution at 15-25 °C. Turn on a...

Embodiment 3

[0038] (1) Collect the reaction solution after the degradation treatment in Example 2, centrifuge to remove the liquid, and the carbon nitride solid in the graphite phase is washed and separated by secondary water and ethanol, dried at 80°C for 12 h, and cooled to room temperature Put the reclaimed graphite phase carbon nitride into a mortar and grind for 30 min to obtain powdered graphite phase carbon nitride;

[0039] (2) Measure 100 mL of wastewater containing 10 mg / L methylene blue dye into a photodegradation quartz reactor, add 100 mg of recovered graphite phase carbon nitride, and stir for 30 min in the dark to make graphite phase carbon nitride and methylene blue The dye is fully functional; take 2 mL of the reaction solution and filter it through a needle filter of 0.22 μm, put the filtrate into a brown centrifuge tube and save it, turn on the circulating cooling water and continue to stir to keep the temperature of the reaction solution at 15-25 ℃, turn on 300 Light t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com