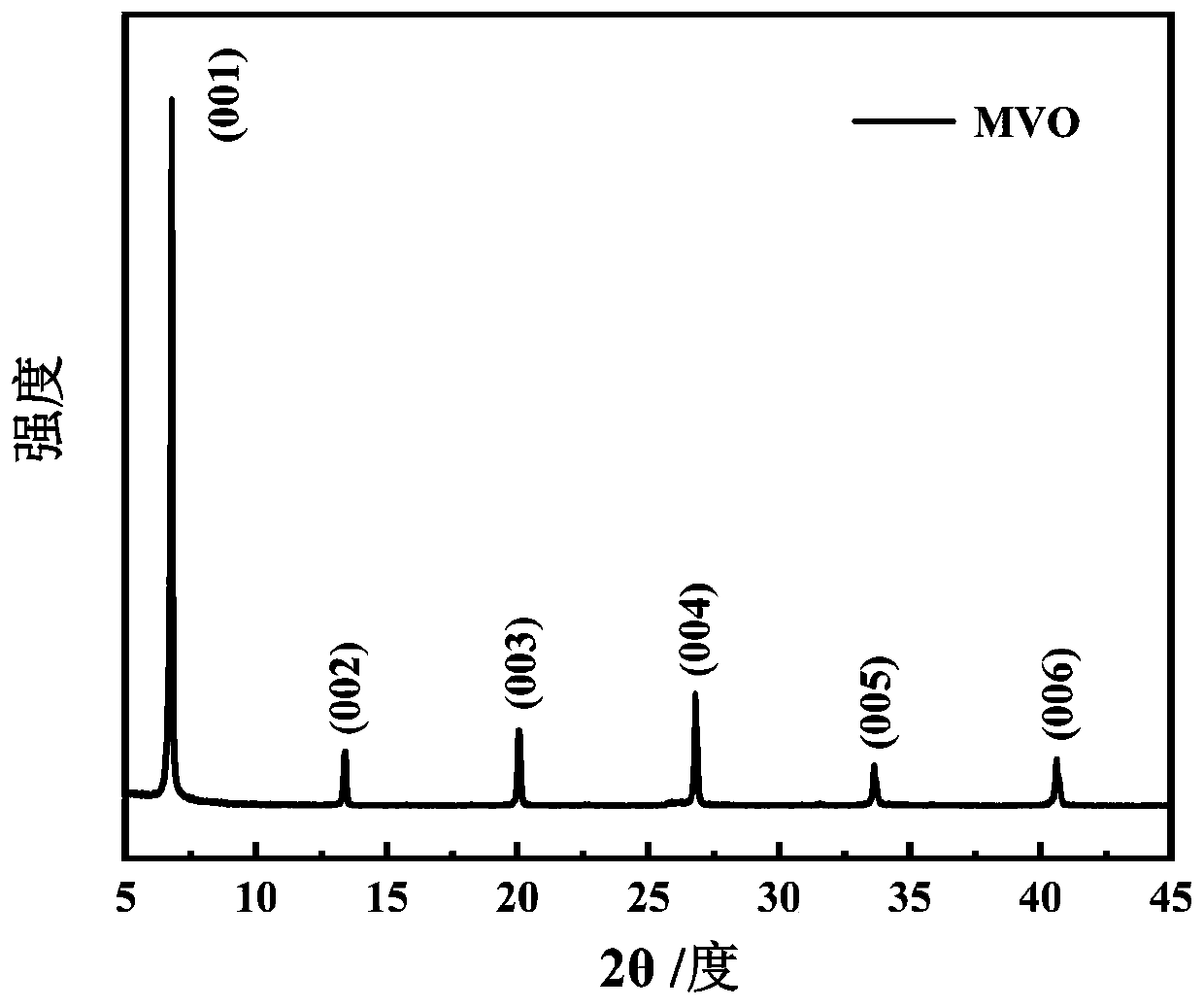

Aqueous zinc ion battery vanadium-based positive electrode material and preparation method and application thereof

A zinc-ion battery, cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of poor rate performance, limited capacity, low cycle stability, etc., achieve high specific capacity, easy to achieve, obvious economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

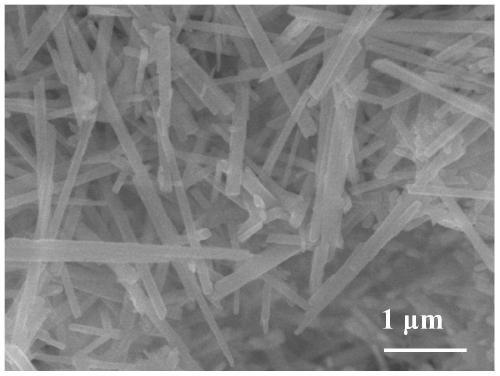

[0034] In this embodiment, a method for preparing a vanadium-based cathode material for an aqueous zinc-ion battery comprises the following steps:

[0035] a. 3mmol vanadium oxide V 2 o 5 Put it into a beaker, add 24mL deionized water, and stir in a water bath at 40°C for 30 minutes to form an orange-yellow solution, which is called solution A;

[0036] b. the hydrogen peroxide that 6ml mass percent concentration is 30wt.% is dripped in the solution A prepared in step a that the water bath is stirred, continue to stir 60min under the water bath condition of described step (1), form dark brown homogeneous solution , called solution B;

[0037] c. Put 1 mmol of magnesium acetate into a beaker, add 10 ml of deionized water, and stir until the magnesium acetate is completely dissolved to form a colorless and transparent solution, which is called solution C;

[0038] d. Drop the solution C prepared in step c into the solution B prepared in step b in the water bath stirring, cont...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, and the special features are:

[0047] In this embodiment, a method for preparing a vanadium-based cathode material for an aqueous zinc-ion battery comprises the following steps:

[0048] a. This step is identical with embodiment 1 step;

[0049] B. this step is identical with embodiment 1 step;

[0050] c. Put 1 mmol of magnesium chloride into a beaker, add 10 ml of deionized water, and stir until the magnesium chloride is completely dissolved to form a colorless transparent solution, which is called solution C;

[0051] d. This step is the same as that of Example 1;

[0052] e. This step is the same as that in Example 1.

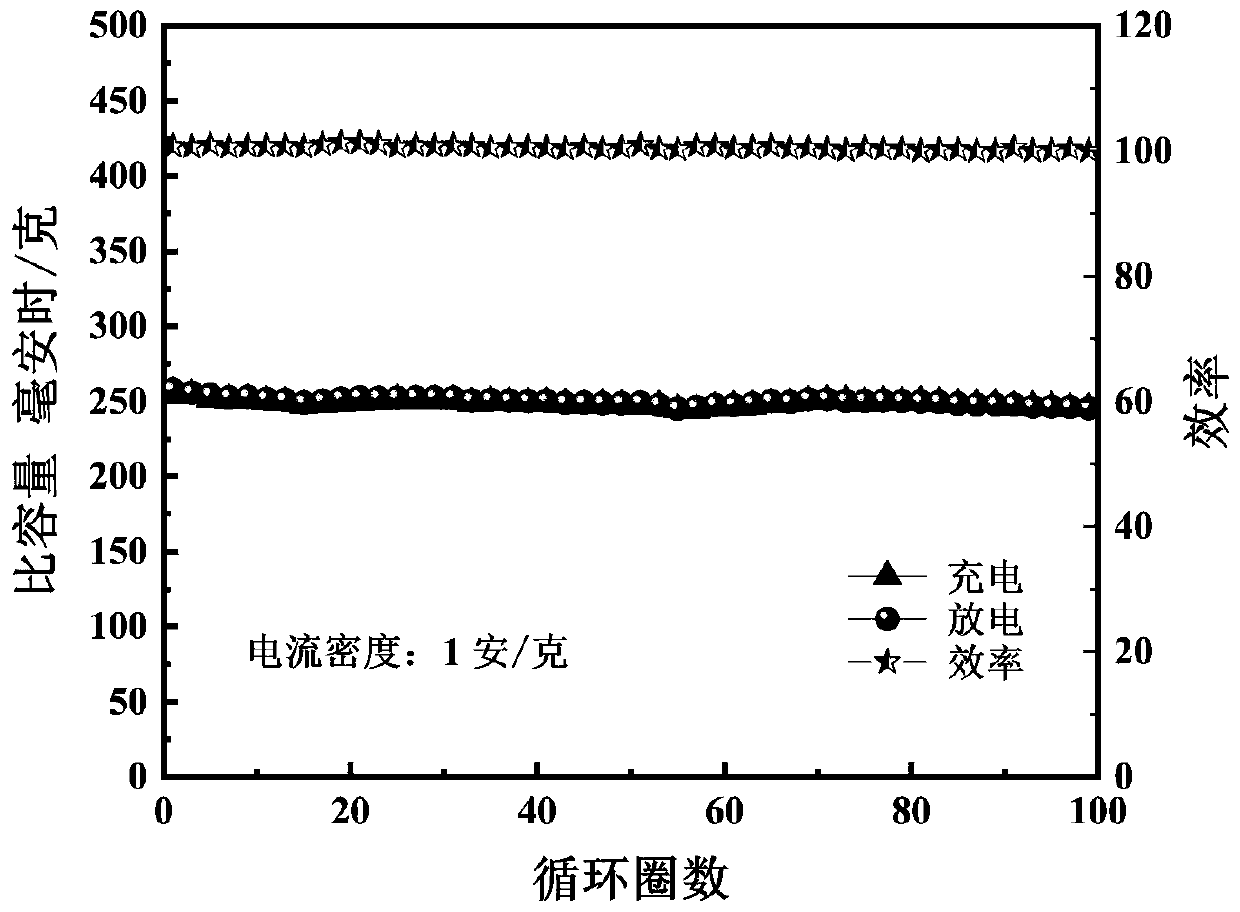

[0053] Experimental test analysis:

[0054] The zinc ion battery positive electrode material obtained by the method of this embodiment was subjected to battery assembly and electrochemical performance testing. The zinc ion battery prepared by the method of this embodiment is 1A g at a curre...

Embodiment 3

[0056] This embodiment is basically the same as the previous embodiment, and the special features are:

[0057] In this embodiment, a method for preparing a vanadium-based cathode material for an aqueous zinc-ion battery comprises the following steps:

[0058] a. This step is identical with embodiment 1 step;

[0059] B. this step is identical with embodiment 1 step;

[0060] c. Put 1 mmol of magnesium nitrate into a beaker, add 10 ml of deionized water, and stir until the magnesium nitrate is completely dissolved to form a colorless and transparent solution, which is called solution C;

[0061] d. This step is the same as that of Example 1;

[0062] e. This step is the same as that in Example 1.

[0063] Experimental test analysis:

[0064] The zinc ion battery positive electrode material obtained by the method of this embodiment was subjected to battery assembly and electrochemical performance testing. The zinc ion battery prepared by the method of this embodiment is 1A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com