Method for removing acetaminophen in water based on in-situ Fenton reaction

A technology of acetaminophen and Fenton reaction, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as increased process complexity, secondary pollution of water body, increased removal cost, etc., to achieve Avoid secondary chemical pollution and eliminate damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

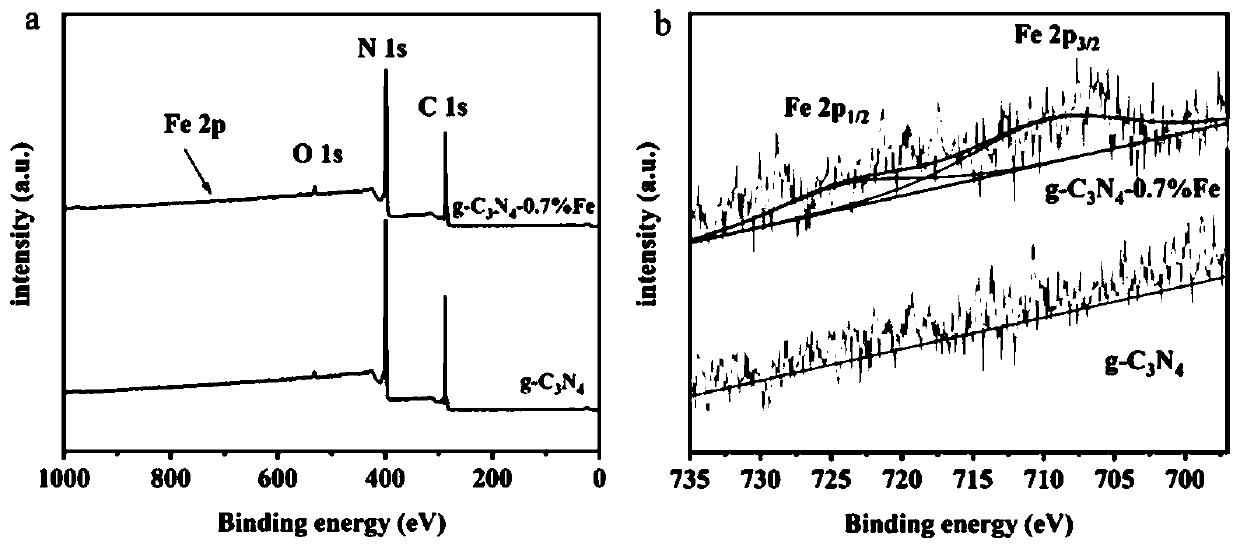

[0028] 1. Iron-doped graphitic carbon nitride (Fe / g-C 3 N 4 ) preparation

[0029] Add 3 g of melamine (C 3 h 6 N 6 ) powder, add 3.2, 6.4, 12.8, 32, 44.8, 64mg ferric chloride hexahydrate (FeCl 3 ·6H 2 O), then add 100mL H 2 O and 5mL concentrated hydrochloric acid, stirred and evaporated to dryness at 100°C to obtain the precursor, heated to 550°C at a rate of 5°C / min in a muffle furnace, then kept at temperature for 3 hours, cooled to room temperature, and obtained different iron content of 0.05% , 0.1%, 0.2%, 0.5%, 0.7%, 1.0% Fe / g-C 3 N 4 , the obtained product was ultrasonically washed three times with 100 mL deionized water and 100 mL ethanol respectively, and the product was put into an oven and dried at 80° C. for 12 hours.

[0030] 2. Paracetamol removal experiment

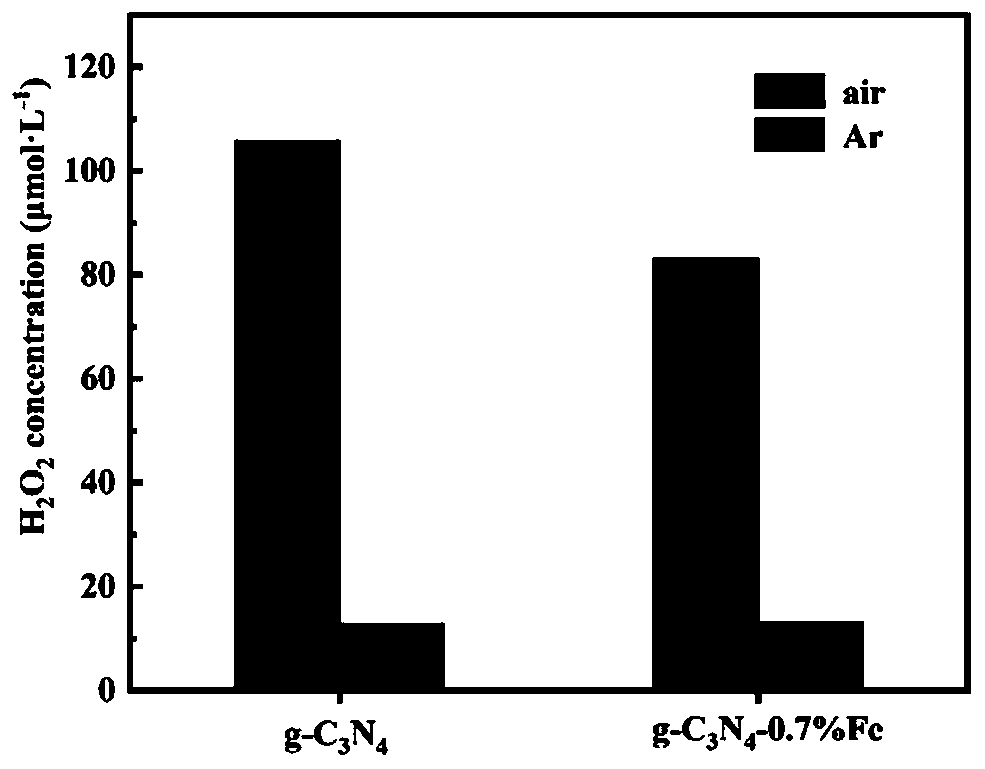

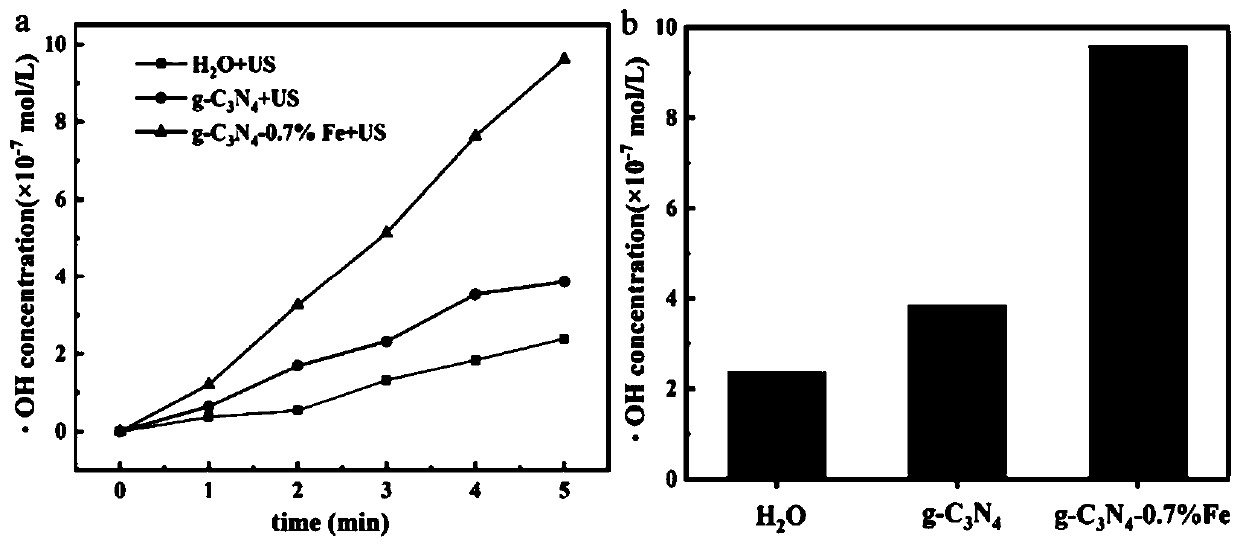

[0031] Add 100 mL of acetaminophen aqueous solution containing 50 μM to a 250 mL three-necked flask, and then add 100 mg (1.0 g / L) of g-C prepared above containing 0.7% Fe. 3 N 4, and then tur...

Embodiment 2

[0033] In a 250mL three-necked flask, add 100mL of acetaminophen aqueous solution containing 50 μM, and then add 100mg (1.0g / L) of g-C prepared in Example 1 containing different contents of Fe. 3 N 4 , and then turn on the ultrasound (300W) to start the reaction under the condition that the oxygen content is 7.8mg / L, take a sample every 15min, centrifuge the sample for 10 minutes under the condition of 3000rpm, and measure the content of acetaminophen in the supernatant under optimized conditions concentration. After 60 minutes of reaction, acetaminophen was mixed with 0.0%, 0.05%, 0.1%, 0.2%, 0.5% and 1% Fe / g-C 3 N 4 The degradation rate in is followed by: 48%, 58%, 71%, 88%, 92% and 92% ( Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com