Method for preparing methyl methacrylate through aldol condensation of methyl propionate and formaldehyde and multi-stage reaction system

A technology of methyl methacrylate and methyl propionate, applied in the field of methyl methacrylate synthesis, can solve the problems of catalyst running loss, high equipment cost, low reaction conversion rate and the like, achieve stable product quality and reduce operation load, the effect of reducing the variation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

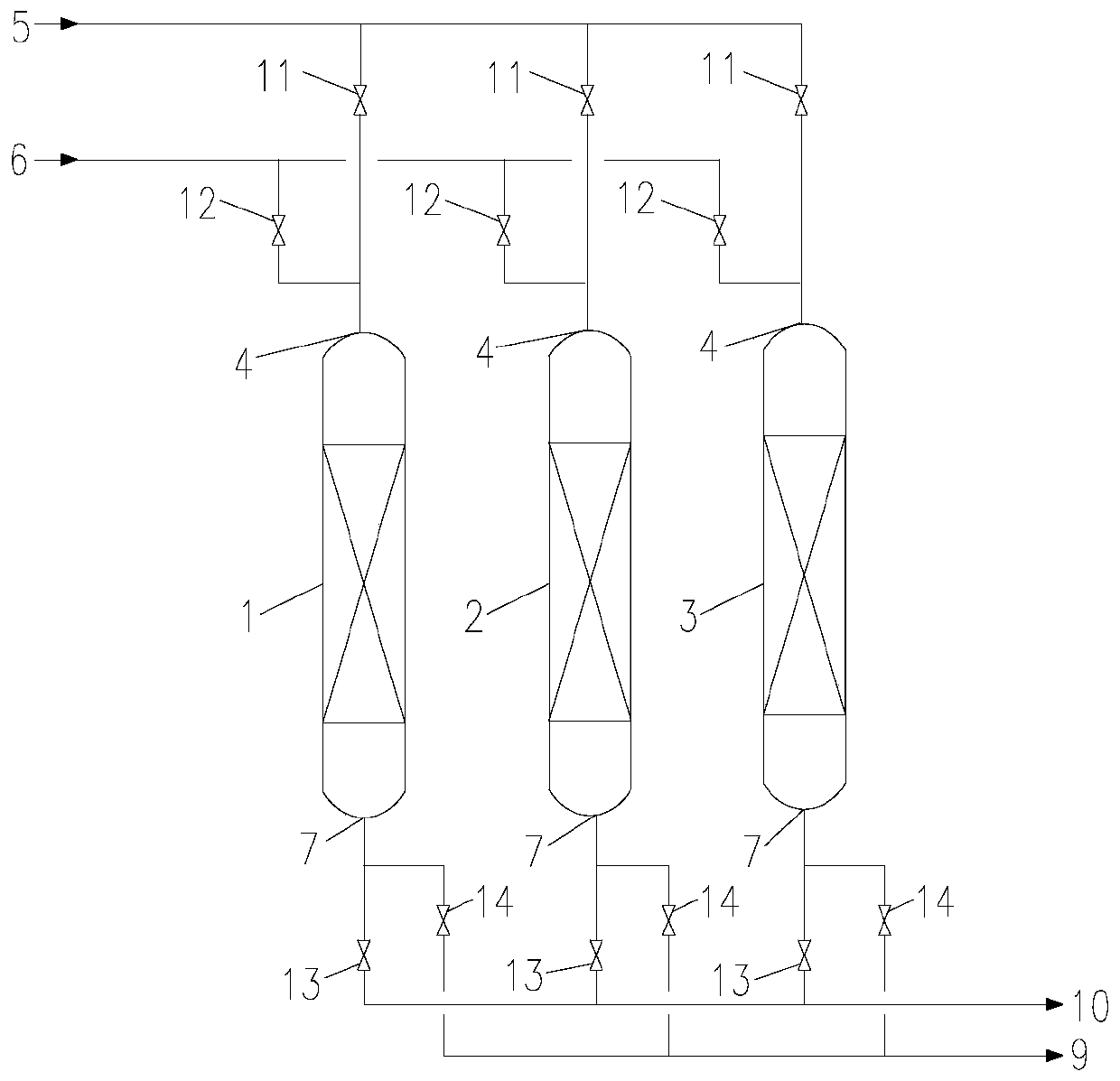

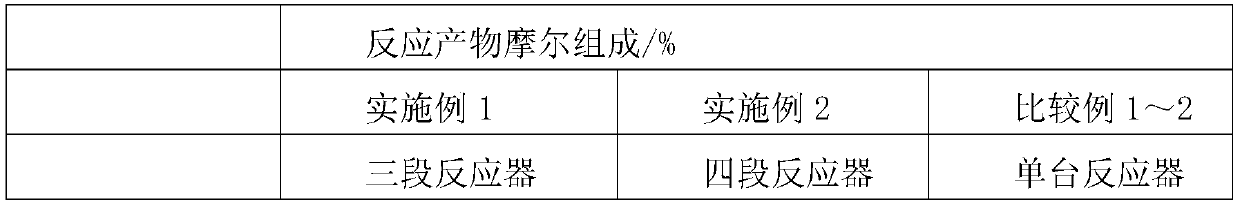

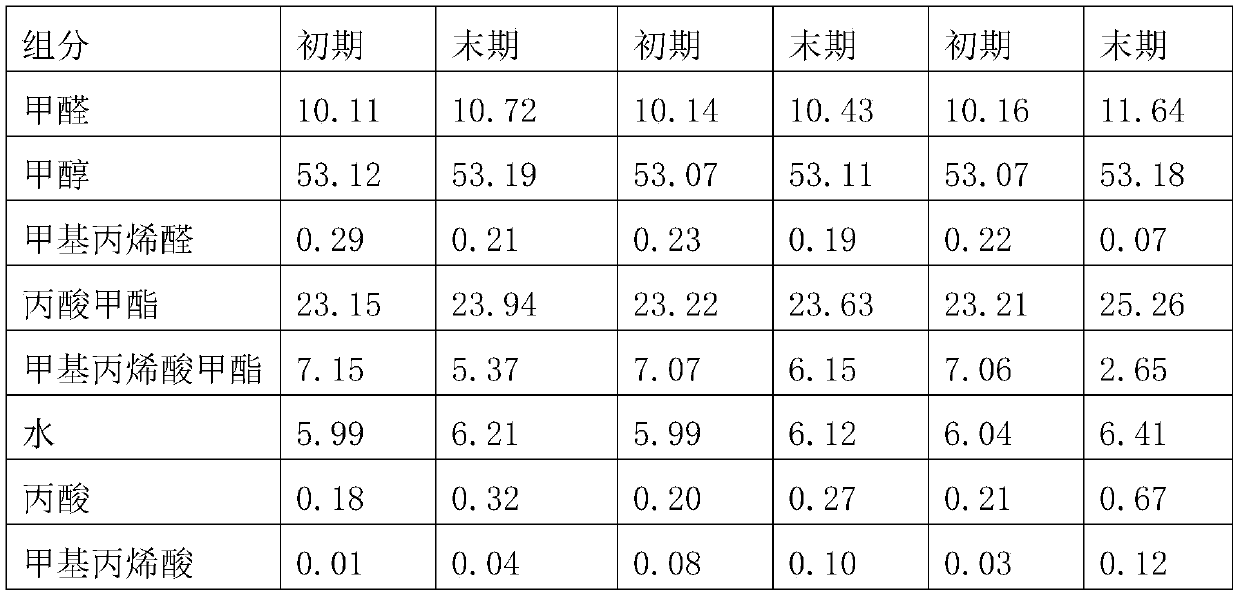

[0049] Such as figure 1 Shown methyl propionate and formaldehyde aldol method condensation to prepare the multistage reactor process of methyl methacrylate, it comprises the first section reactor 1, the second section reactor 2 and the third section reactor 3, wherein, There are two stages for reaction and one for catalyst regeneration. The reaction process conditions are: the weight hourly space velocity is 3 / h, the reaction pressure is normal pressure, the reaction temperature is 330°C, the molar ratio of raw material methyl propionate to formaldehyde is 2:1, and the molar ratio of formaldehyde to methanol is 1:4 ; The regeneration process conditions are: the volumetric space velocity is 600 / h, the regeneration temperature is 400°C, and the regeneration pressure is normal pressure. The life of the catalyst is 336 hours, that is, it needs to be regenerated after 336 hours of reaction, and each reactor is switched at an interval of 168 hours. The composition of the initial st...

Embodiment 2

[0051] A multi-stage reactor for the condensation of methyl propionate and formaldehyde to produce methyl methacrylate, which includes a first-stage reactor, a second-stage reactor, a third-stage reactor and a fourth-stage reactor, among which there are three One stage reactor is used for reaction, and one stage is used for catalyst regeneration. The reaction process conditions are: the weight hourly space velocity is 3 / h, the reaction pressure is normal pressure, the reaction temperature is 330°C, the molar ratio of raw material methyl propionate to formaldehyde is 2:1, and the molar ratio of formaldehyde to methanol is 1:4 ; The regeneration process conditions are: the volumetric space velocity is 600 / h, the regeneration temperature is 400°C, and the regeneration pressure is normal pressure. The life span of the catalyst is 336h, that is, regeneration is required after 336h of reaction, and each reactor is switched at an interval of 112 hours. The composition of the initial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com