Wave-absorbing material based on biological waste and magnetic material waste and preparation method of wave-absorbing material

A technology of magnetic materials and biological waste, applied in chemical instruments and methods, other chemical processes, magnetic field/electric field shielding, etc., can solve problems affecting the ecological environment, occupying land resources, etc., and achieve low cost, excellent wave-absorbing performance, high density small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

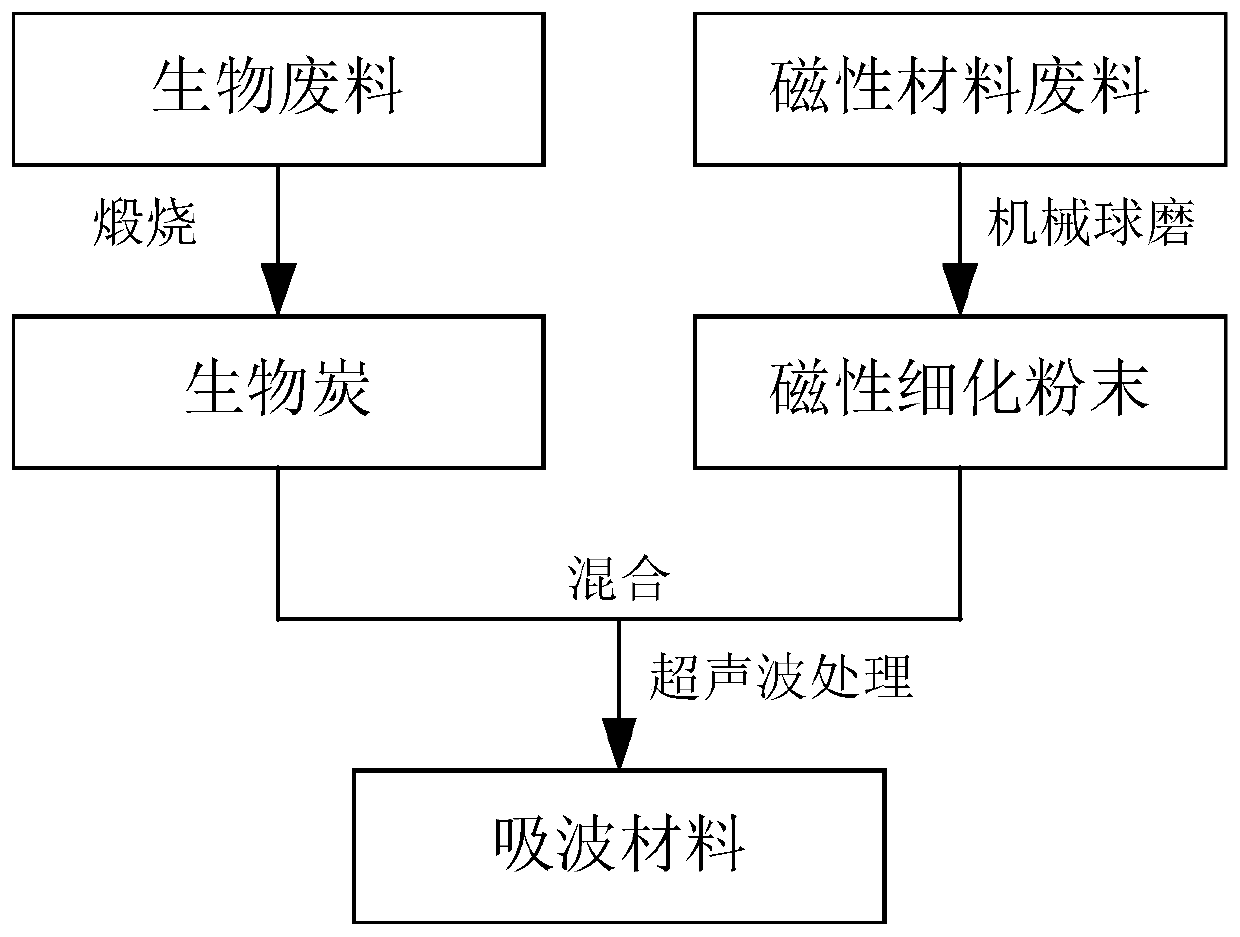

[0027] Such as figure 1 As shown, a method for preparing a wave-absorbing material based on biological waste and magnetic material waste may specifically include the following steps:

[0028] Step 1. After the biological waste is dried in the air environment, it is mixed with zinc chloride, and then placed in a tube furnace under the protection of a protective gas (the protective gas can be nitrogen or a rare gas, but preferably nitrogen) Carry out calcination, and wash the product obtained by calcination with HCL aqueous solution (0.1Mol), distilled water and ethanol, remove the residue, adjust the pH value of the product to be neutral at the same time, and then dry it in an oven at 60°C to 80°C to prepare get biochar.

[0029] Step 2: Perform mechanical ball milling on the magnetic material waste, the ball milling time is 8-24 hours, the ball milling speed is 400-500 rpm, and the mass ratio of ball to material is 20-40, so as to obtain magnetic fine powder with a particle s...

Embodiment 1

[0047] A kind of wave-absorbing material based on biological waste and magnetic material waste, its preparation method comprises the following steps:

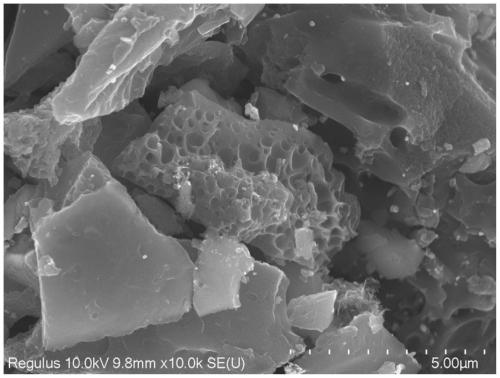

[0048] Step 1. Put the coffee grounds in an oven and dry them at 90°C for 12 hours, mix them with zinc chloride according to the weight ratio of dried coffee grounds: zinc chloride = 1:0.5, and then put the mixture into a tube furnace Calcination is carried out under the protection of nitrogen. The calcination process is to raise the temperature from room temperature to 900°C at a rate of 10°C / min, and heat at a constant temperature for 1 hour; the calcined product is washed with HCL aqueous solution (0.1Mol), distilled water and ethanol to remove residue, while adjusting the pH value of the product to be neutral, and then drying it in an oven at 60°C to obtain biochar (the morphology of the biochar is shown in image 3 shown).

[0049] Step 2, block magnetic material scrap (MnFe 2 o 4 ) for mechanical ball milling, the ball...

Embodiment 2

[0054] A kind of wave-absorbing material based on biological waste and magnetic material waste, its preparation method comprises the following steps:

[0055] Step 1. Put the coffee grounds in an oven and dry them at 90°C for 12 hours, mix them with zinc chloride according to the weight ratio of dried coffee grounds: zinc chloride = 1:0.5, and then put the mixture into a tube furnace Calcination is carried out under the protection of nitrogen. The calcination process is to raise the temperature from room temperature to 900°C at a rate of 10°C / min, and heat at a constant temperature for 1 hour; the calcined product is washed with HCL aqueous solution (0.1Mol), distilled water and ethanol to remove The residue was adjusted to a neutral pH value, and then dried in an oven at 60°C to prepare biochar.

[0056] Step 2, block magnetic material scrap (MnFe 2 o 4 ) to carry out mechanical ball milling, the ball milling speed is 500rpm, the mass ratio of ball to material is 30:1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com