Oil-based drilling fluid drilling cutting processing while drilling system of offshore petroleum and natural gas platform

A technology of oil-based drilling fluid and offshore oil, which is applied in earthwork drilling, wellbore flushing, wellbore/well parts, etc., and can solve the problems of unsatisfactory handling while drilling offshore, easy plugging of superheated steam bushings, and insufficient steam preparation. Convenience and other issues, to achieve the effect of simple operation, simple structure, high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

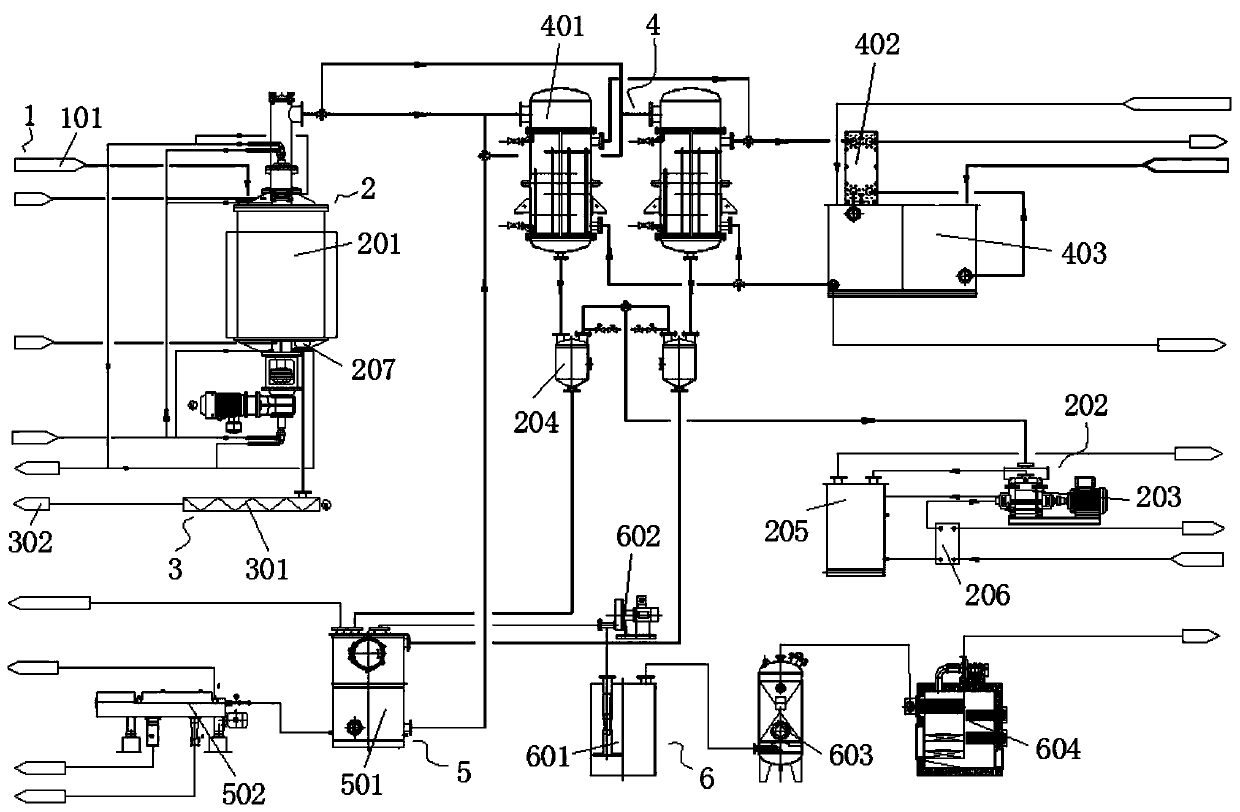

[0028] see figure 1 , an oil-based drilling fluid cuttings processing system while drilling on an offshore oil and gas platform, including a feed conveying unit 1 connected to an external oil-base drilling fluid cuttings collection system, and the outlet of the feed conveying unit 1 is electrically connected There is a thermal desorption unit 2, the outlet of the desorption slag in the thermal desorption unit 2 is connected to a discharge conveying unit 3, and the outlet of the oil-water mixture in the thermal desorption unit 2 is connected to a condensation unit 4, and the condensation unit 4 An oil-water separation unit 5 is connected to the outlet of the oil-water separation unit 5, and a tail gas purification unit 6 is provided at the outlet of the oil-water separation unit 5; specifically, the thermal desorption unit 2 is composed of a reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com