Antibacterial, antistatic and stain-release down-proof fabric and preparation method thereof

An easy decontamination and antistatic technology, applied in the field of textile manufacturing, can solve the problems of fabric technology, complex structure, complex fabric technology, high production cost, etc., and achieve the effect of easy care, soft hand feeling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

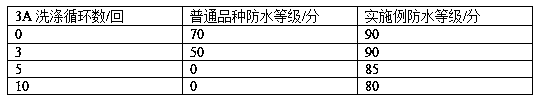

Examples

Embodiment 1

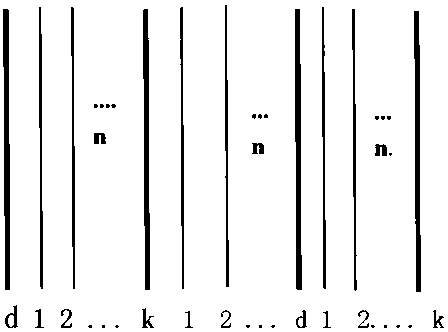

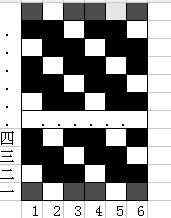

[0030] (1) Weaving of antibacterial and antistatic interwoven fabric: the warp yarn is made of superfine polyester DTY filaments (75D, the number of multifilaments in the fiber cross-section is ≧144), and the weft yarn is made of every 6 superfine polyester DTY filaments, and one conductive fiber is added Filament (20D white copper sulfide conductive filament, provided by Shanghai Guilian Masterbatch Co., Ltd.), after 6 superfine polyester DTY filaments, add 2 antibacterial polyester DTY filaments (75D copper antibacterial polyester filament , provided by Shanghai Aoling Textile New Material Co., Ltd.), 2 / 1 left twill weave is used for high-density weaving on the machine, and the weaving tightness is not less than 95%;

[0031] (2) Preparation of three-proof, easy-to-decontamination and anti-drilling velvet finishing solution: In deionized water, add fluorine-containing polyacrylate finishing agent and special aliphatic polymer cationic compound emulsion containing silicone, an...

Embodiment 2

[0035] (1) Weaving of antibacterial and antistatic interwoven fabric: the warp yarn is made of superfine polyester DTY filament (75D, the number of multifilaments in the fiber cross-section is ≧144), and the weft yarn is made of every 7 superfine polyester DTY filaments, and one conductive fiber is added Filament (20D white copper sulfide conductive filament, provided by Shanghai Guilian Masterbatch Co., Ltd.), after 7 superfine polyester DTY filaments, add 3 antibacterial polyester DTY filaments (75D copper antibacterial polyester filament , provided by Shanghai Aoling Textile New Material Co., Ltd.), 2 / 1 left twill weave is used for high-density weaving on the machine, and the weaving tightness is not less than 95%;

[0036] (2) Prepare three-proof, easy-to-decontamination and anti-drilling velvet finishing solution: in deionized water, add perfluorobutylsulfonic acid and special aliphatic polymer cationic compound emulsion containing organic silicon successively, and adjust ...

Embodiment 3

[0040] (1) Weaving of antibacterial and antistatic interwoven fabric: the warp yarn is made of superfine polyester DTY filaments (75D, the number of multifilaments in the fiber cross-section is ≧144), and the weft yarn is made of every 5 superfine polyester DTY filaments, adding 1 conductive yarn Filament (20D white copper sulfide conductive filament, provided by Shanghai Guilian Masterbatch Co., Ltd.), after 5 superfine polyester DTY filaments, add 1 antibacterial polyester DTY filament (75D copper antibacterial polyester filament , provided by Shanghai Aoling Textile New Material Co., Ltd.), 2 / 1 left twill weave is used for high-density weaving on the machine, and the weaving tightness is not less than 95%;

[0041] (2) Preparation of three-proof, easy-to-decontamination and anti-drilling velvet finishing solution: In deionized water, add fluorine-containing polyacrylate finishing agent and special aliphatic polymer cationic compound emulsion containing silicone, and adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com