Electrochromic material, composition, preparation method, electrochromic device, shell assembly and electronic equipment

A technology of electrochromic materials and electrochromic devices, applied in the direction of color-changing fluorescent materials, electrical equipment shells/cabinets/drawers, electrical components, etc., can solve problems such as low contrast, material layering, and slow electrochromic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

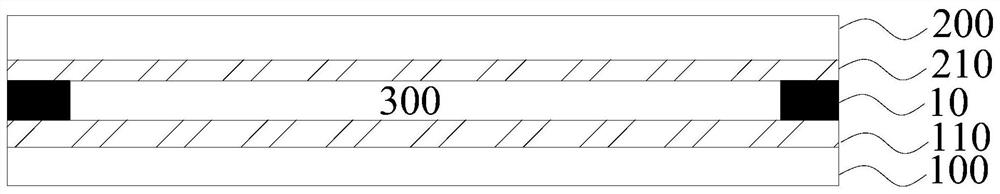

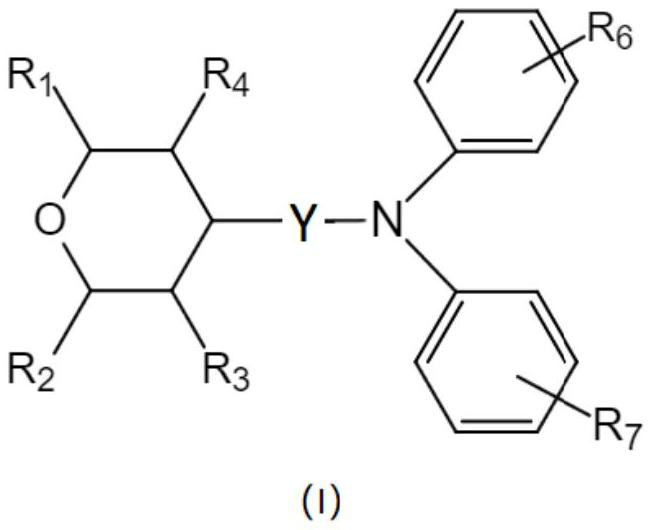

[0062] Prepare the anode electrochromic material, the structural formula of the anode electrochromic material is as follows:

[0063]

[0064] Dissolve 19.7g of 4,4'-dimethyldiphenylamine and 19.3g of 4-(2-bromoethyl)tetrahydro-2H-pyran in 500g of toluene, stir and mix evenly to obtain a mixed solution, and then press potassium carbonate and The molar ratio of 4-(2-bromoethyl)tetrahydro-2H-pyran is 1:1. Add potassium carbonate, then add 2g of cuprous iodide, raise the temperature to 60-90℃, heat and condense and reflux for 4-96h to obtain the following formula: The crude product of the anode electrochromic material represented by the structural formula (1); the crude product is recrystallized with acetonitrile to obtain a refined anode electrochromic material.

[0065] The reaction product is 1 H-NMR and 13 C-NMR analysis confirms that it is the target product, and the analysis results are as follows:

[0066] 1H-NMR (300MHz, CDCL 3 ): δ6.84(4H), δ6.31(4H), δ3.6(2H), δ3...

example 2

[0069] Prepare the anode electrochromic material, the structural formula of the anode electrochromic material is as follows:

[0070]

[0071] Dissolve 22.9g of 4,4'-dimethoxydiphenylamine and 16.5g of 4-bromotetrahydropyran in 500g of toluene, stir and mix evenly to obtain a mixed solution, and Add potassium carbonate at a ratio of 1:1, then add 1.5g of cuprous iodide, heat up to 60-90°C, heat and condense to reflux for 4-96h, and obtain the crude anode electrochromic material shown in structural formula (2); The crude product is recrystallized with acetonitrile or toluene to obtain a refined anode electrochromic material shown in structural formula (2).

[0072] The reaction product is 1 H-NMR and 13 C-NMR analysis confirms that it is the target product, and the analysis results are as follows:

[0073] 1H-NMR (300MHz, CDCL 3 ): δ6.55(4H), δ6.32(4H), δ3.73(2H), δ3.6(2H), δ2.73(1H), δ1.78(2H).

[0074] 13C-NMR (75MHz, CDCL 3 ): 150.2, 141.4, 120.1, 115.2, 64.6, 55.9,...

example 3

[0076] Prepare the anode electrochromic material, the structural formula of the anode electrochromic material is as follows:

[0077]

[0078] Dissolve 23.7 g of m-trifluoromethyl diphenylamine and 22.6 g of 4-(iodomethyl) tetrahydropyran in 500 g of toluene, stir and mix to obtain a mixed solution, and then press potassium carbonate and 4-(iodomethyl) tetrahydropyran The molar ratio of hydropyran is 1:1. Add potassium carbonate, then add 1g of cuprous iodide, heat up to 60-90°C, heat and condense to reflux for 4-96h, and obtain the crude anode electrochromic material shown in structural formula (3) ; The crude product is recrystallized with acetonitrile or toluene to obtain a refined anode electrochromic material shown in structural formula (3).

[0079] The reaction product is confirmed to be the target product through 1H-NMR and 13C-NMR analysis, and the analysis results are as follows:

[0080] 1H-NMR (300MHz, CDCL3): δ7.04(2H), δ6.97(1H), δ6.77(1H), δ6.62(1H), δ6.58(1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com