Method for preparing aluminide coating on surface of nickel-based metal through electrophoresis

A base metal, aluminide technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of high cost, expensive equipment, difficult to promote in a large area, etc. weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

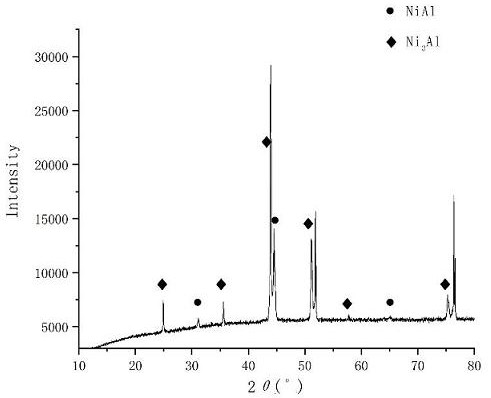

Embodiment 1

[0024] In absolute ethanol, add high-purity Al powder with a particle size of 50nm and 500nm in sequence, with a mass concentration of 0.1g / L and 0.3g / L, and ultrasonically disperse evenly; then add polyvinyl carbonate and MgCl 2 , the mass concentrations are 0.1g / L and 0.6g / L respectively, stir to dissolve completely, and obtain the electrophoretic suspension; the high-purity nickel sheet is immersed in the electrophoretic suspension and used as the cathode, and the lead plate is used as the anode for electrophoretic deposition, and the electrophoretic working voltage is 40V , after every 15 seconds of deposition, take it out and dry it before electrophoresis, and repeat the deposition 3 times; after the electrophoresis process, put the nickel sheet into the tube atmosphere furnace, use argon as the protective gas, and raise it to 300°C at a speed of 5°C / min. After 1 hour of heat preservation, heat up to 500°C at a speed of 5°C / min and hold for 0.5 hours, then heat up to 750°C...

Embodiment 2

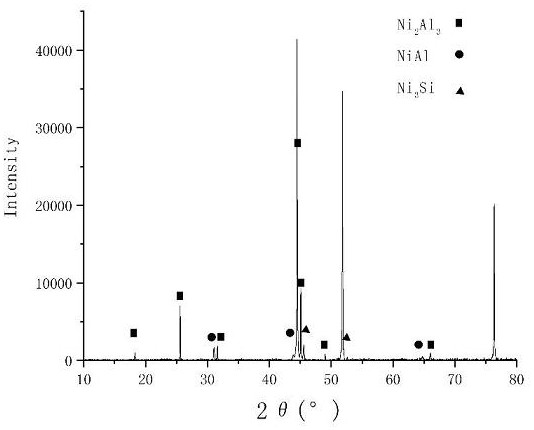

[0026] In absolute ethanol, add high-purity Al powder with a particle size of 100nm, 200nm and 1um in sequence, with mass concentrations of 0.1g / L, 0.2g / L and 0.6g / L, and high-purity silicon powder with a particle size of 50nm, The mass concentration is 0.1g / L, and the ultrasonic dispersion is uniform; then add polypropylene carbonate and MgCl 2 , the mass concentration is 0.3g / L and 0.8g / L respectively, stir to make it dissolve completely, and obtain the electrophoretic suspension; the high-purity nickel sheet is immersed in the electrophoretic suspension and used as the cathode, and the lead plate is used as the anode for electrophoretic deposition, and the electrophoretic working voltage is 50V , every 16 seconds after deposition, take it out and dry it before electrophoresis, and repeat the deposition 4 times; after the electrophoresis process, put the nickel sheet into the tube atmosphere furnace, use argon as the protective gas, and raise it to 300°C at a speed of 10°C / mi...

Embodiment 3

[0028] In absolute ethanol, add high-purity Al powder with a particle size of 1um, 10um, and 20um in sequence, with a mass concentration of 10g / L, 4g / L, and 1g / L, and ultrasonically disperse evenly; then add polyvinyl carbonate and MgCl 2 , the mass concentrations are 1g / L and 1.6g / L respectively, stir to make it dissolve completely, and obtain the electrophoretic suspension; the high-purity nickel sheet is immersed in the electrophoretic suspension and used as the cathode, and the lead plate is used as the anode for electrophoretic deposition, and the electrophoretic working voltage is 100V. After every 20 seconds of deposition, take it out and dry it before electrophoresis, and repeat the deposition 5 times; after the electrophoresis process, put the nickel sheet into a tube-type atmosphere furnace, use argon as the protective gas, and raise it to 300°C at a speed of 15°C / min. After 1 hour, raise the temperature to 660°C at a speed of 15°C / min and keep it for 1 hour, then rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com