A kind of graphene/metallocene composite supercapacitor electrode material and its preparation method and application

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. It can solve the problems of complex preparation process, high cost, and small specific capacitance, so as to achieve simple operation, promote the flow of electrons, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

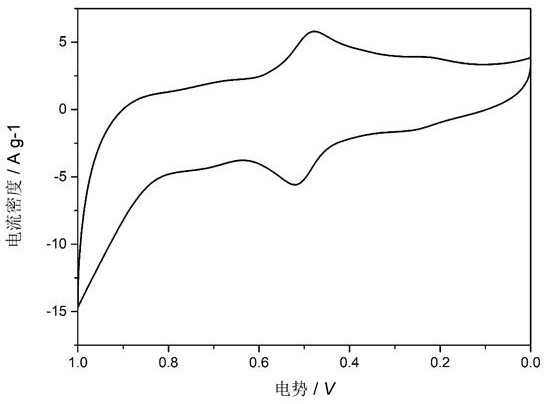

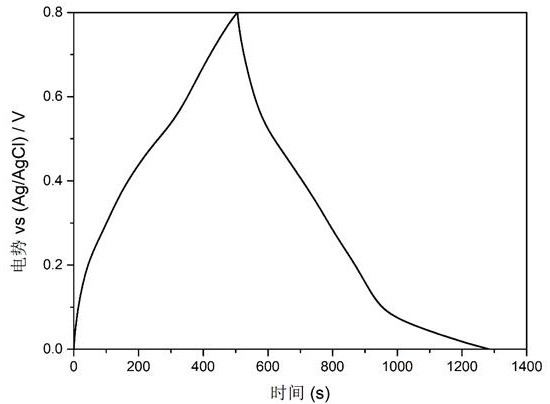

Image

Examples

Embodiment 1

[0040] (1) Preparation of isocyanate-terminated graphene oxide: Disperse 100 mg of graphene oxide in 25 ml of anhydrous N,N-dimethylformamide, ultrasonically disperse for 0.5 hours and add 100 mg of p-phenylene diisocyanate under stirring. Under the protection of nitrogen, react at 10°C for 12 hours. After the reaction, the suspension is suction-filtered, washed with anhydrous N,N-dimethylformamide and dichloromethane respectively, and dried in a vacuum oven at 60°C for 12 hours after suction filtration. , to obtain isocyanate-terminated graphene oxide.

[0041] (2) Preparation of graphene / metallocene composite supercapacitor electrode material: 100 mg of isocyanate-terminated graphene oxide was ultrasonically dispersed in 25 ml of anhydrous N,N-dimethylformamide for 0.5 hours, and then 20 mg of 1, 1'-ferrocenedicarboxylic acid, reacted at 10°C for 12 hours under the protection of nitrogen, after the reaction, the suspension was filtered with suction and washed with anhydrous ...

Embodiment 2

[0043] (1) Preparation of isocyanate-terminated graphene oxide: Disperse 100 mg of graphene oxide in 25 ml of anhydrous N,N-dimethylformamide, ultrasonically disperse for 1 hour and add 300 mg of p-phenylene diisocyanate under stirring. Under the protection of nitrogen, react at 20°C for 24 hours. After the reaction, the suspension is suction-filtered, washed with anhydrous N,N-dimethylformamide and dichloromethane respectively, and dried in a vacuum oven at 60°C for 12 hours after suction filtration. , to obtain isocyanate-terminated graphene oxide.

[0044] (2) Preparation of graphene / metallocene composite supercapacitor electrode material: 100 mg of isocyanate-terminated graphene oxide was ultrasonically dispersed in 25 ml of anhydrous N,N-dimethylformamide for 1 hour, and then 50 mg of 1, 1'-ferrocenedicarboxylic acid, reacted at 25°C for 24 hours under the protection of nitrogen, after the reaction, the suspension was suction-filtered and washed with anhydrous N,N-dimethy...

Embodiment 3

[0046](1) Preparation of isocyanate-terminated graphene oxide: Disperse 100 mg of graphene oxide in 25 ml of anhydrous N,N-dimethylformamide, ultrasonically disperse for 1.5 hours, add 600 mg of p-phenylene diisocyanate under stirring, in Under the protection of nitrogen, react at 25°C for 36 hours. After the reaction, the suspension is suction-filtered, washed with anhydrous N,N-dimethylformamide and dichloromethane respectively, and dried in a vacuum oven at 60°C for 12 hours after suction filtration. , to obtain isocyanate-terminated graphene oxide.

[0047] (2) Preparation of electrode materials for graphene / metallocene composite supercapacitors: 100 mg of isocyanate-terminated graphene oxide was ultrasonically dispersed in 25 ml of anhydrous N,N-dimethylformamide for 1.5 hours, and then 100 mg of 1, 1'-ferrocenedicarboxylic acid, reacted at 25°C for 36 hours under the protection of nitrogen. After washing and suction filtration, dry at 60° C. in a vacuum oven for 12 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com