Chitosan/nano-metal composite hydrogel as well as preparation method and application thereof

A composite hydrogel and nano-metal technology, which is applied in the field of chitosan/nano-metal composite hydrogel and its preparation, can solve the problems of low dispersion and poor load stability, and achieve simple process, convenient operation and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

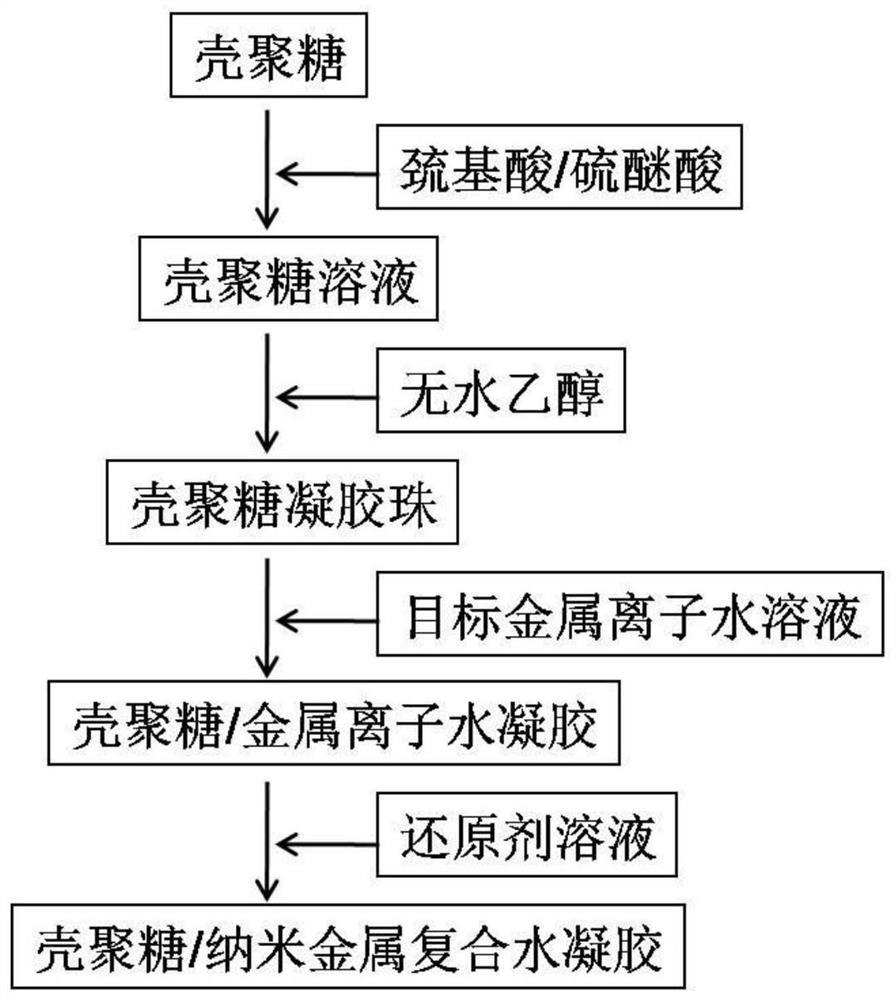

[0045] The steps of the preparation method of the present invention are as follows:

[0046] (1) choosing deacetylation degree is 50% chitosan as raw material;

[0047] (2) 0.1wt% chitosan, mercaptoacid or thioether acid 0.1wt% and the rest of the water are mixed;

[0048] (3) placing the mixture at 20° C. for 8 h to obtain a homogeneous chitosan solution;

[0049] (4) After the homogeneous chitosan solution is centrifuged and defoamed, drop ethanol in a volume ratio of 1:5 to form a spherical chitosan gel;

[0050] (5) Place the spherical chitosan gel in a solution containing the target metal ion, the metal ion concentration is 0.01 mg / mL, shake at room temperature for 48 hours, and absorb the target metal ion;

[0051] (6) Place the gel adsorbed with the target metal ion in a volume ratio of 1:10 in a sodium borohydride solution with a concentration of 0.01 mol / L and shake at room temperature for 48 hours to obtain a chitosan / nano-metal composite hydrogel.

Embodiment 2

[0053] The steps of the preparation method of the present invention are as follows:

[0054](1) choosing deacetylation degree is 100% chitosan as raw material;

[0055] (2) 10wt% chitosan, mercapto acid or 30wt% thioether acid and the remainder of water are mixed;

[0056] (3) placing the mixture at 80° C. for 1 h to obtain a homogeneous chitosan solution;

[0057] (4) After the homogeneous chitosan solution is centrifuged and degassed, it is dripped with ethanol at a volume ratio of 1:10 to form a spherical chitosan gel;

[0058] (5) Place the spherical chitosan gel in a solution containing the target metal ion, the metal ion concentration is 100 mg / mL, shake at room temperature for 1 hour, and absorb the target metal ion;

[0059] (6) Place the gel adsorbed with the target metal ion at a volume ratio of 1:100 in a sodium borohydride solution with a concentration of 10 mol / L and shake at room temperature for 1 h to obtain a chitosan / nano-metal composite hydrogel.

Embodiment 3

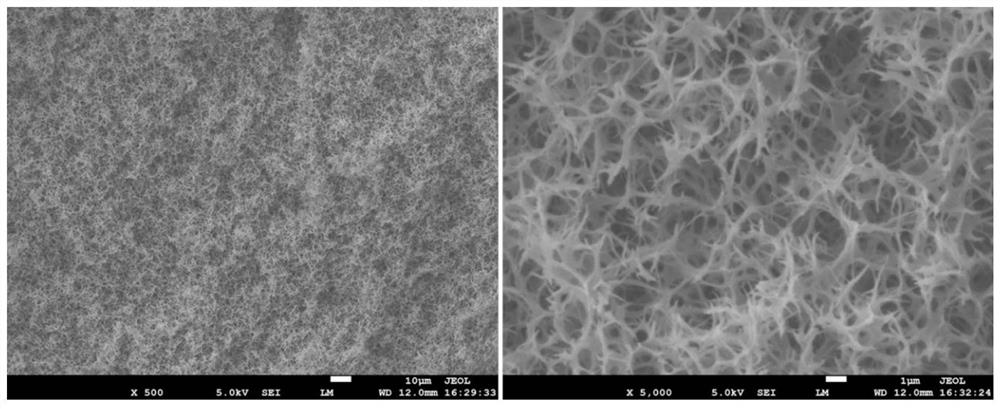

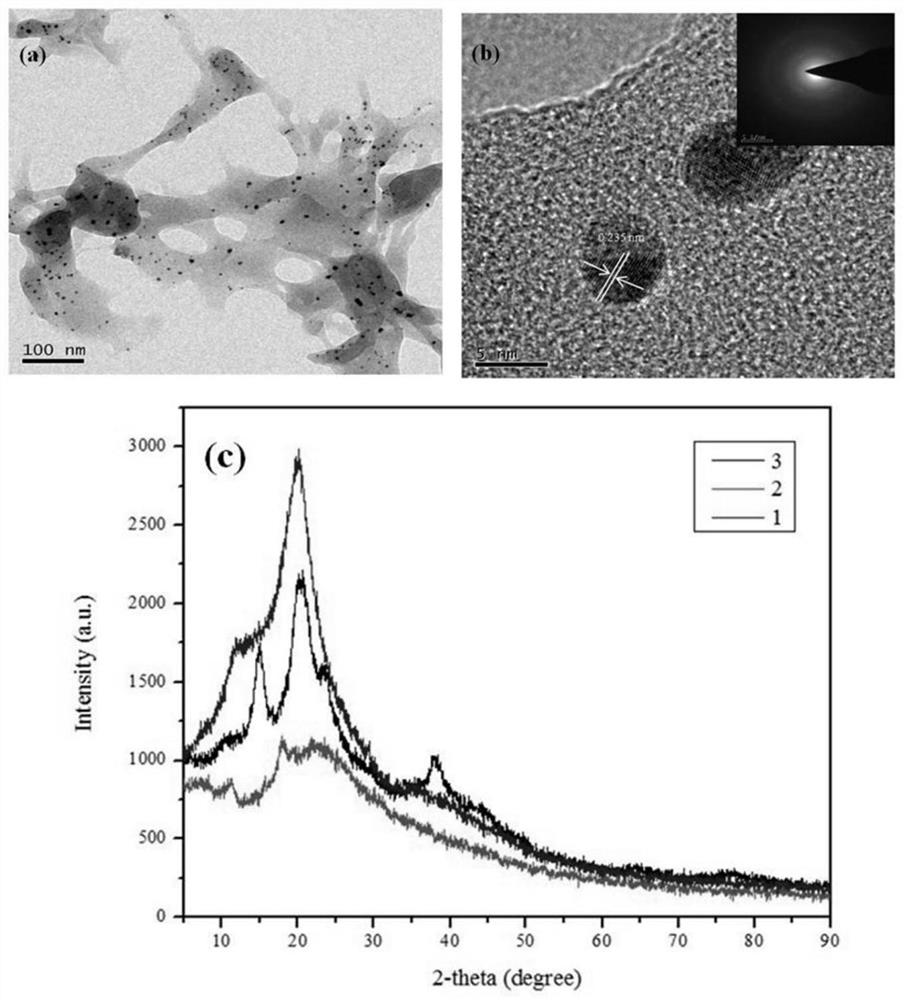

[0061] According to the steps of Example 1, weigh 1.25 grams of crab shell chitosan, 0.394 grams of 3-mercaptopropionic acid, 0.279 grams of thiomalic acid and 20 mL of deionized water, and add them together to a round bottom flask at a temperature of 80 ° C. Mechanically stirred for 6h to obtain a homogeneous solution of chitosan. The chitosan solution was subjected to centrifugal defoaming at a speed of 10,000 rpm, and the chitosan solution was dropped dropwise into 3 times the amount of absolute ethanol using a disposable syringe to form chitosan gel beads with a diameter of 3 mm. The hydrogel beads were soaked in absolute ethanol for 2 h to age. Transfer 300 chitosan gel beads to 50mL, 1.5mM sodium chloraurate aqueous solution and shake at 25°C for 24h, then transfer the chitosan gel column to 30mL, 0.1M sodium borohydride aqueous solution in Keep shaking at 25° C. for 2 hours to reduce the loaded Au(III) to nano-gold to obtain chitosan / nano-gold composite hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com