Morphology regulation and control and preparation method of nano silicon dioxide powder

A nano-silicon dioxide and powder technology, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of cumbersome steps, long cycle, and high requirements for hard templates, and achieves green and clean methods, simple preparation methods, and high efficiency. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of silica nanopowder:

[0025] (1) Add 15 mg of absolute ethanol to 220 mg of distilled water, and ultrasonically oscillate evenly to obtain solution 1;

[0026] (2) Under ultrasonic vibration, add 11 mg tetraethyl orthosilicate (TEOS) into solution 1, and ultrasonically oscillate for 30 minutes to obtain solution 2;

[0027] (3) Adjust the pH value of solution 2 to 10 with 0.1M ammonia water, then add 121mg polyvinylpyrrolidone (PVP), 33mgNaBr and 11mgNaNO 3 , and the obtained reaction system was stirred and reacted at a reaction temperature of 70° C. for 4 hours to obtain a solution 3;

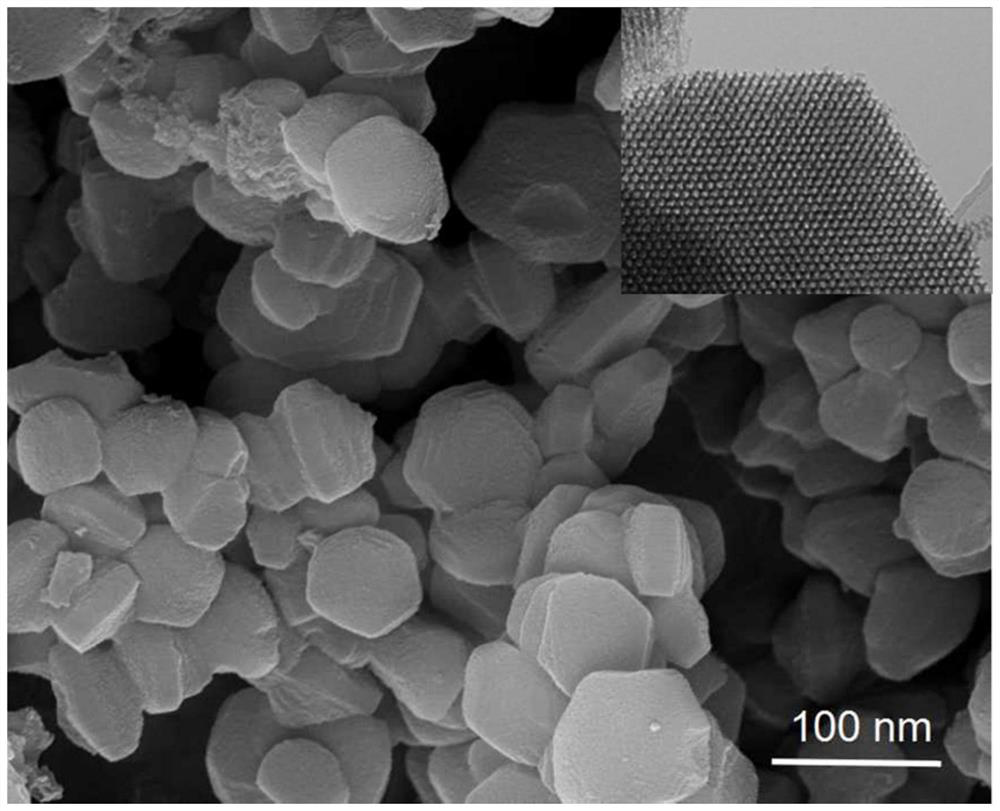

[0028] (4) Solution 3 is centrifugally washed with absolute ethanol, then washed with water, and vacuum-dried for 20 hours to obtain a nano-silica powder with a flaky shape. Since the length of the pore of the flaky shape is relatively shorter than that of the traditional spherical The particles are shorter and have better application in the field of catalysts, ...

Embodiment 2

[0030] A preparation method of silica nanopowder:

[0031] (1) Add 15 mg of absolute ethanol to 220 mg of distilled water, and ultrasonically oscillate evenly to obtain solution 1;

[0032] (2) Under ultrasonic vibration, add 11 mg tetraethyl orthosilicate (TEOS) into solution 1, and ultrasonically oscillate for 30 minutes to obtain solution 2;

[0033] (3) Adjust the pH value of solution 2 to 10 with 0.1M ammonia water, then add 121mg polyvinylpyrrolidone (PVP), 11mgNaBr and 33mgNaNO 3 , and the obtained reaction system was stirred and reacted at a reaction temperature of 70° C. for 4 hours to obtain a solution 3;

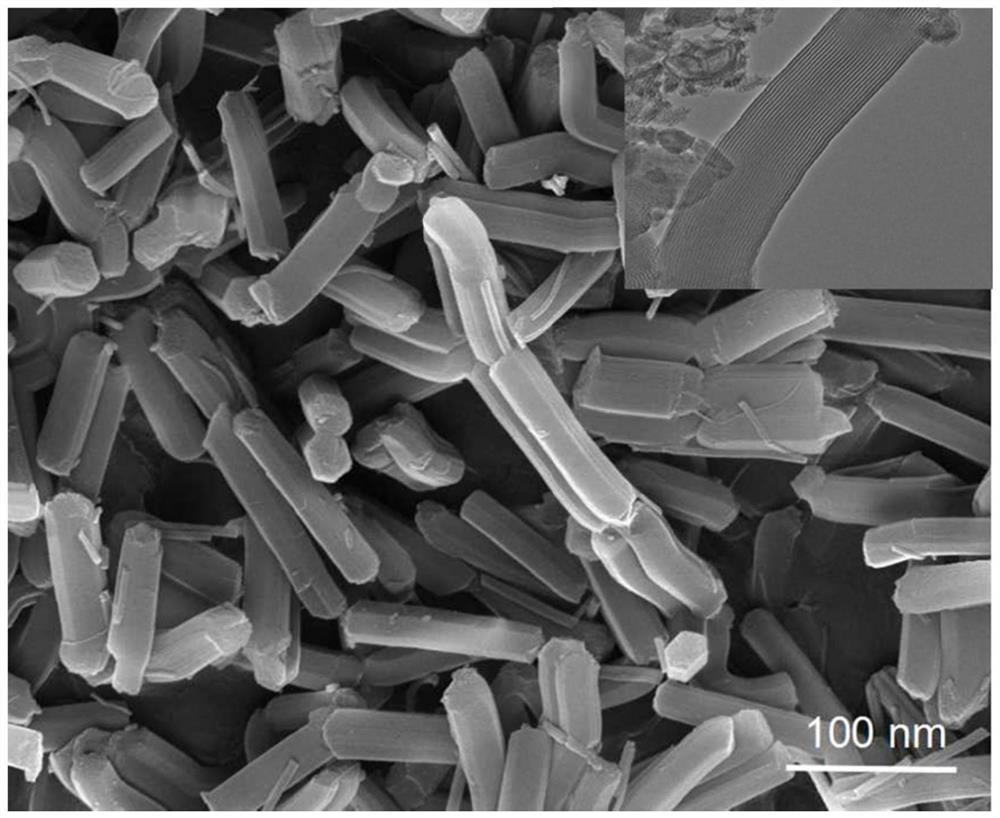

[0034] (4) The solution 3 was centrifuged and washed with absolute ethanol, then washed with water, and vacuum-dried for 20 hours to obtain a nano-silica powder with rod-like morphology. Because the silica pore length of rod-shaped shape is relatively long with respect to the flaky powder pore channel of traditional spherical powder and embodiment 1 (as figure ...

Embodiment 3

[0036] A preparation method of silica nanopowder:

[0037] (1) Add 15 mg of absolute ethanol to 220 mg of distilled water, and ultrasonically oscillate evenly to obtain solution 1;

[0038] (2) Under ultrasonic vibration, add 11 mg tetraethyl orthosilicate (TEOS) into solution 1, and ultrasonically oscillate for 30 minutes to obtain solution 2;

[0039] (3) Adjust the pH value of solution 2 to 10 with 0.1M ammonia water, then add 121mg polyvinylpyrrolidone (PVP), 22mgNaBr and 22mgNaNO 3 , and the obtained reaction system was stirred and reacted at a reaction temperature of 70° C. for 4 hours to obtain a solution 3;

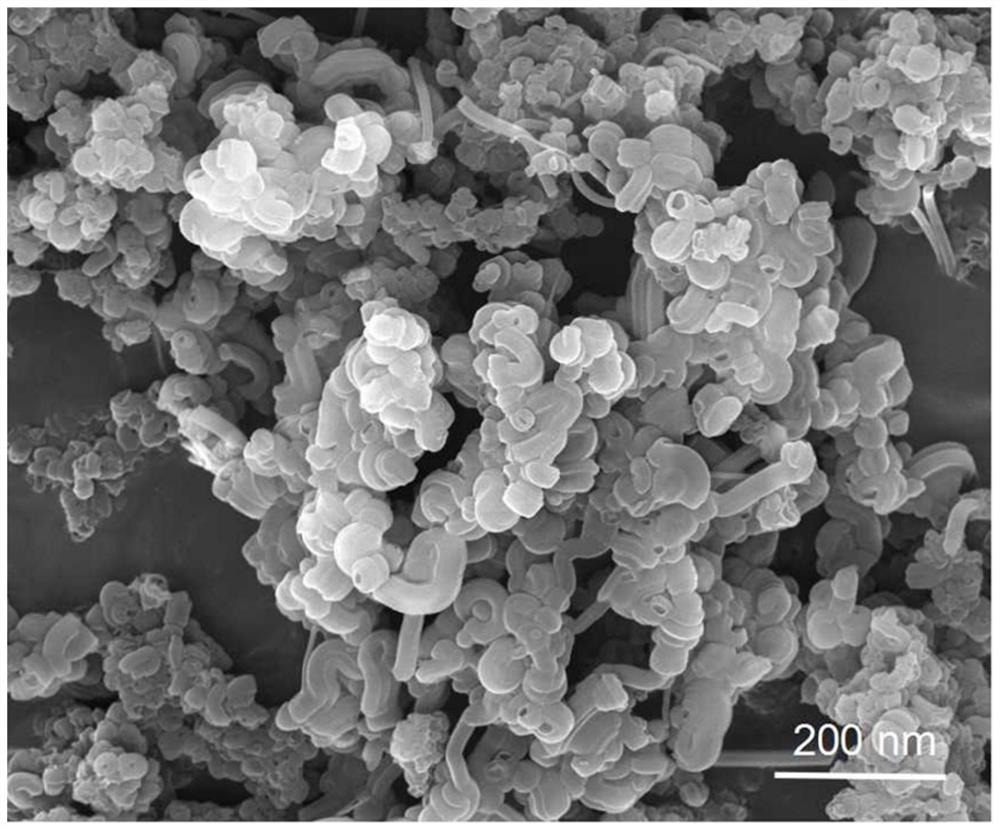

[0040] (4) The solution 3 was washed by centrifugation with absolute ethanol, then washed with water, and vacuum-dried for 20 hours to obtain a nano-silica powder with a transitional morphology of rods and sheets, thus proving that Br - and NO 3 - The relative addition amount is the key to inducing the formation of silica with flake or rod-like morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com