A kind of preparation method of high entropy oxide material

An oxide and high-entropy technology, which is applied in the field of preparation of high-entropy oxide materials, can solve problems such as high-entropy oxide materials that have not yet been retrieved, and achieve the effects of uniform morphology, reduced energy consumption, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

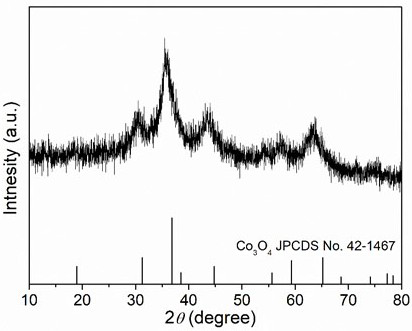

[0022] Weigh 2.424 g of Fe(NO 3 ) 3 9H 2 O, 2.25 g of Al(NO 3 ) 3 9H 2 O, 1.746 g of Co(NO 3 ) 2 ·6H 2 O, 1.746 g of Ni(NO 3 ) 2 ·6H 2 O, 1.782 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 60 mL deionized water and stirred evenly to obtain a mixed solution of metal salts; then 0.72 g of urea was weighed and added to the above mixed solution, and stirred evenly; then the above mixed solution was transferred to a polytetrafluoroethylene-lined reactor , heated to 120°C, reacted for 1 h, cooled to room temperature, filtered the reaction solution with deionized water, and washed three times with deionized water to obtain a hydroxide solid powder; finally put the above solid powder into a low-temperature plasma reactor for reaction 20 min (the reaction atmosphere is oxygen, the radio frequency power is 300 W), and the high entropy oxide is obtained. XRD spectrum ( figure 1 ) shows that the prepared (FeAlCoNiZn) 3 o 4 High-entropy oxides have a spinel structure.

Embodiment 2

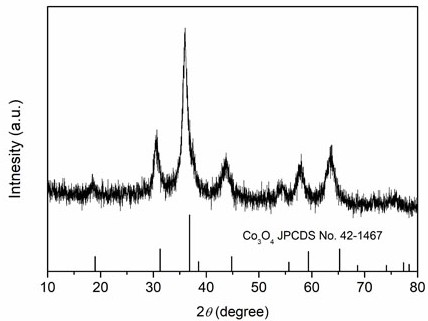

[0024] Weigh 2.424 g of Fe(NO 3 ) 3 9H 2 O, 2.4 g of Cr(NO 3 ) 3 9H 2 O, 1.746 g of Co(NO 3 ) 2 ·6H 2 O, 1.746 g of Ni(NO 3 ) 2 ·6H 2 O, 1.782 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 60 mL deionized water and stirred evenly to obtain a mixed solution of metal salt; then 2.52 g of hexamethylenetetramine was weighed and added to the mixed solution, and stirred evenly; then the mixed solution was transferred to polytetrafluoroethylene In an ethylene-lined reactor, heat to 140°C, react for 1 h, and after cooling to room temperature, filter the reaction solution with suction and wash with deionized water three times to obtain a hydroxide solid powder; finally put the above solid powder into a low-temperature plasma The high-entropy oxide was obtained by reacting in a bulk reactor for 20 min (the reaction atmosphere was oxygen, and the radio frequency power was 400 W). XRD spectrum ( figure 2 ) shows that the prepared (FeCrCoNiZn) 3 o 4 High-entropy oxides have a...

Embodiment 3

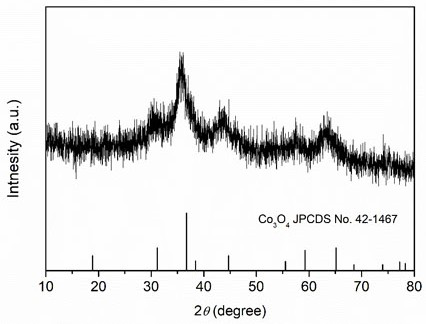

[0026] Weigh 2.424 g of Fe(NO 3 ) 3 9H 2 O, 2.4 g of Cr(NO 3 ) 3 9H 2 O, 1.746 g of Co(NO 3 ) 2 ·6H 2 O, 1.746 g of Ni(NO 3 ) 2 ·6H 2 O, 1.45 g of Cu(NO 3 ) 2 ·6H 2 O was dissolved in 60 mL deionized water and stirred evenly to obtain a mixed solution of metal salts; then 2.09 g of arginine was weighed and added to the mixed solution of metal salts, and stirred evenly; then the mixed solution was transferred to a polytetrafluoroethylene liner In the reaction kettle, heat to 100°C, react for 1 h, and after cooling to room temperature, filter the reaction solution with suction and wash with deionized water for 3 times to obtain a hydroxide solid powder; finally, put the above solid powder into a low-temperature plasma reactor The high-entropy oxides were obtained after 20 min reaction (the reaction atmosphere was oxygen, and the radio frequency power was 400 W). XRD spectrum ( image 3 ) shows that the prepared (FeCrCoNiCu) 3 o 4 High-entropy oxides have a spine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com