Spinel type ferrite material based on rare earth element lanthanum or cerium doping

A technology of ferrite materials and rare earth elements, which is applied in the fields of iron compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of not being retrieved, and achieve the effects of simple methods, mild reaction conditions, and short reaction cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Its preparation method includes the following steps:

[0042] The ⑴ A, La and Ce or Fe metal nitrate by 1: x: weighed in a container after a molar ratio of 2-x metal element was added 8 ~ 12 mL ultrapure water was stirred until completely dissolved to obtain a mixed liquid.

[0043] ⑵ mixture was added a precipitating agent, and stirring was continued for 1.0 ~ 2.0 h, the precipitate was obtained pH = 7 to 13. Precipitating agent refers to one or both of sodium carbonate, sodium hydroxide, ammonia water.

[0044]⑶ precipitate was charged to the autoclave after complete seal placed 100 ~ 150 ℃ incubated processing furnace 3 ~ 5 h, then cooled to room temperature to give a solid product.

[0045] ⑷ solid product was filtered and washed with ultrapure water under reduced pressure to pH = 6 ~ 8, precipitate was isolated by suction filtration, 60 ~ 90 ℃ dried 5 ~ 8 h, to give solid powder.

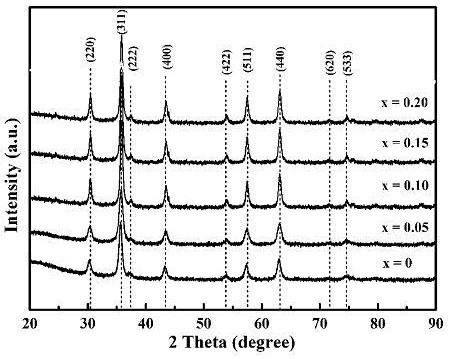

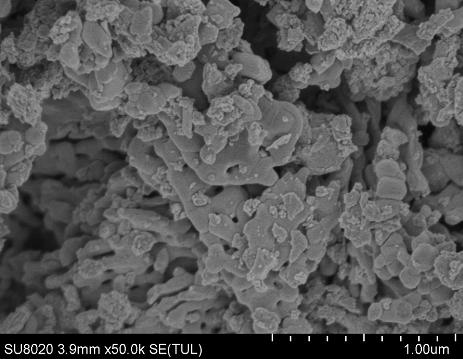

[0046] ⑸ solid powder after the crystallization treatment to obtain good crystallinity o...

Embodiment 1

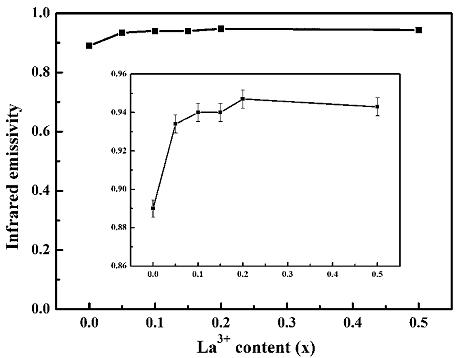

[0048] Example 1 A rare earth element-based embodiment La 3+ Spinel ferrite material which chemical formula NiLa x FE 2-x O 4 .

[0049] 1) NiLa x FE 2-x O 4 (X = 0) is prepared:

[0050] The ⑴ 2.908 g 8.080 g nickel nitrate and ferric nitrate in a container, 10 mL of ultrapure water with stirring until completely dissolved, to obtain a mixture.

[0051] ⑵ mixture was added at a concentration of 30 wt% ammonia water, and stirring was continued for 1.0 ~ 2.0 h, the precipitate obtained was pH = 9.

[0052] The precipitate ⑶ sealing liquid charged in the autoclave was placed 130 ℃ After completion of the processing furnace incubated 4 h, then cooled to room temperature to give a solid product.

[0053] ⑷ solid product was filtered under reduced pressure and washed with ultrapure water to pH = 7, the precipitate was isolated by suction filtration, and dried 70 ℃ 8 h, to give solid powder.

[0054] ⑸ solid powder by heating rate 5 ° / min to a holding furnace for 4 hours at 500 deg.] ...

Embodiment 2

[0071] Example 2 Based on the rare earth element La embodiment 3+ Spinel ferrite material which chemical formula NiLa x FE 2-x O 4 .

[0072] 1) NiLa x FE 2-x O 4 (X = 0) is prepared:

[0073] The ⑴ 2.908 g 8.080 g nickel nitrate and ferric nitrate in a container, was added 8 mL of ultrapure water with stirring until completely dissolved, to obtain a mixture.

[0074] ⑵ mixture was added at a concentration of 30 wt% ammonia water, and stirring was continued for 1.0 ~ 2.0 h, the precipitate solution to obtain pH = 7.

[0075] ⑶ precipitate was charged to the autoclave after complete seal placed 100 ℃ incubated processing furnace 3 h, then cooled to room temperature to give a solid product.

[0076] ⑷ solid product was filtered under reduced pressure and washed with ultrapure water to pH = 6, the precipitate was isolated by suction filtration, and dried 70 ℃ 8 h, to give solid powder.

[0077] ⑸ solid powder by 3 ° / min heating rate holding furnace incubated for 2 hours at 300 deg....

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com