A method for precise control of air-cooling of iron-containing materials, enhanced sorting and simultaneous recovery of latent heat

A material and precise technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of large coercive force of artificial magnetite, reduce the quality of concentrates, reduce the coercive force of iron minerals, etc. Reduce coercivity, improve product quality, reduce the effect of magnetic agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

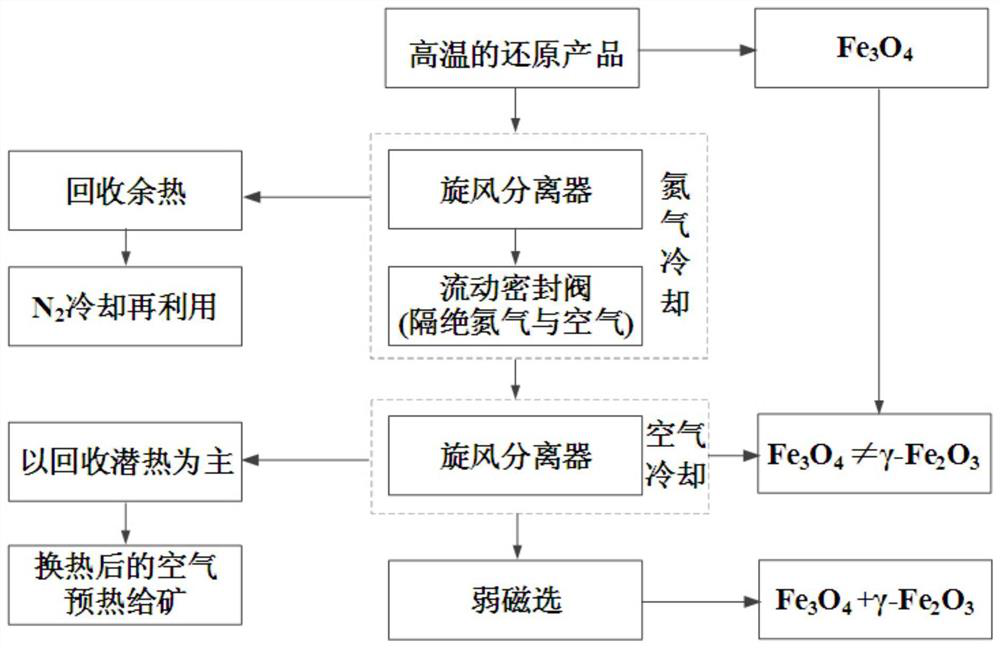

[0046] Process such as figure 1 shown;

[0047] After the iron-containing material is dehydrated and suspended for reduction and roasting, the resulting reduced roasting material is transported to the nitrogen-cooled cyclone separator group; the particle size of the reduced roasting material -0.074mm accounts for 85% of the total mass, and the temperature of the reduced roasting material 530°C, the Fe content of magnetite in the reduced roasting material accounts for 95% of the total Fe in the reduced roasting material; a contact heat exchanger is installed inside the nitrogen cooling cyclone separator group; the iron-containing material is a complex refractory ore;

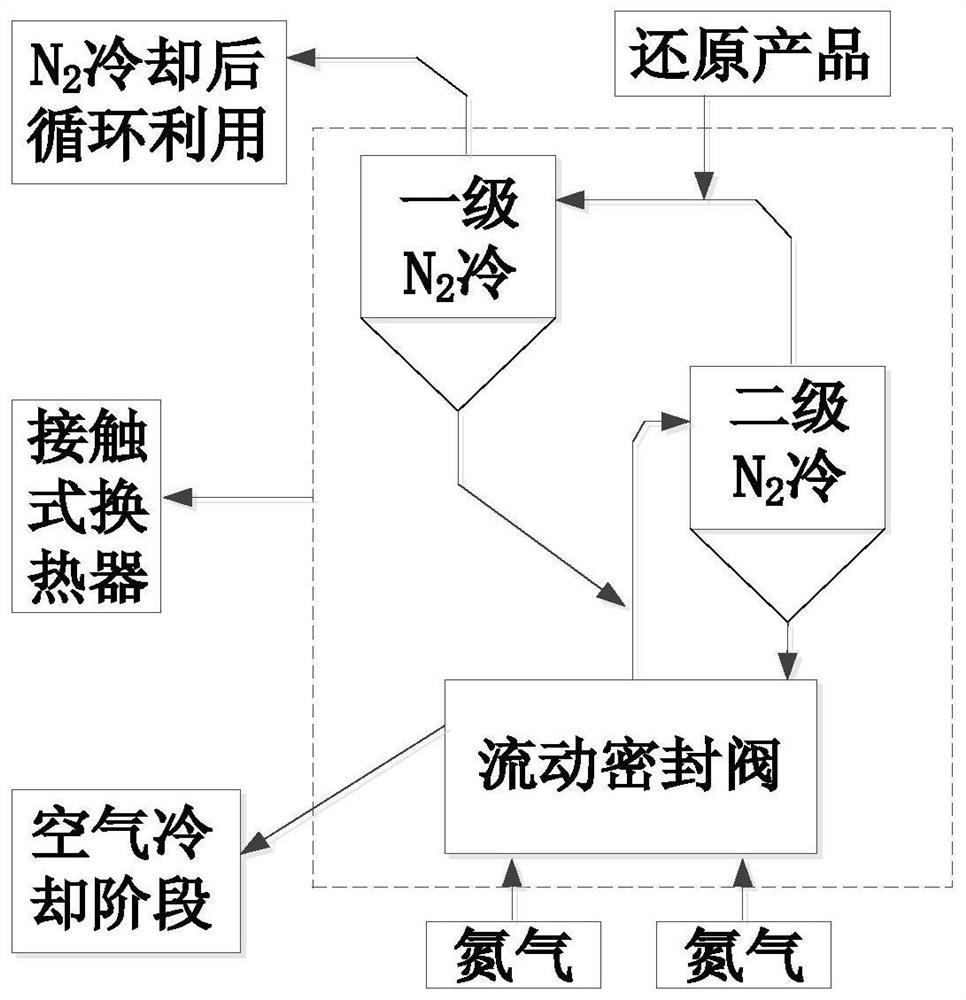

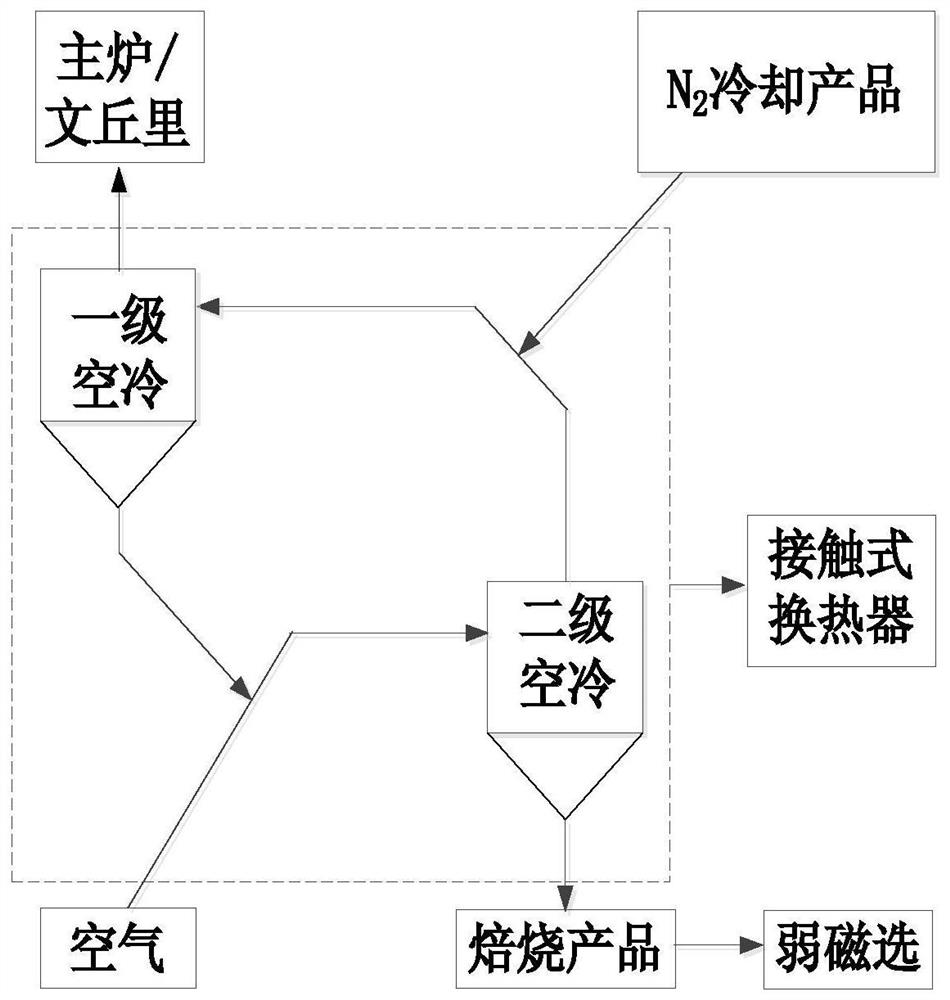

[0048] The nitrogen-cooled cyclone separator group is composed of two-stage nitrogen-cooled cyclone separators. The outlet of the first-stage nitrogen-cooled cyclone separator is connected to the feed port of the second-stage nitrogen-cooled cyclone separator. The second-stage nitrogen-cooled cyclone separator T...

Embodiment 2

[0055] Method is with embodiment 1, and difference is:

[0056] (1) Particle diameter-0.074mm of the reduction roasting material accounts for 80% of the total mass, the temperature of the reduction roasting material is 510° C., and the Fe content of magnetite in the reduction roasting material accounts for 97% of the total Fe in the reduction roasting material;

[0057] (2) The reduced roasted material is cooled to 230°C in the nitrogen cooling cyclone group; the residence time of the reduced roasted material in the nitrogen cooled cyclone group is 20min;

[0058] (3) The residence time of the cooling roasting material in the air-cooling cyclone separator group is 4min;

[0059] (4) The magnetic field intensity of weak magnetic separation is 1300Oe; the iron grade TFe of iron concentrate is 57.36%; the recovery rate of Fe is 84.13%; The iron grade of the concentrate increased by 1.56%, and the iron recovery decreased by 0.57%.

Embodiment 3

[0061] Method is with embodiment 1, and difference is:

[0062] (1) Particle diameter-0.074mm of the reduction roasting material accounts for 77% of the total mass, the temperature of the reduction roasting material is 550 ° C, and the Fe content of magnetite in the reduction roasting material accounts for 93% of the total Fe in the reduction roasting material;

[0063] (2) The reduced calcined material is cooled to 210° C. in the nitrogen cooling cyclone group; the residence time of the reduced calcined material in the nitrogen cooled cyclone group is 25 min;

[0064] (3) The residence time of the cooling roasting material in the air cooling cyclone separator group is 3min;

[0065] (4) the magnetic field intensity 2000Oe of weak magnetic separation; the iron grade TFe57.45% of iron concentrate; The iron grade of the iron concentrate was increased by 1.67%, and the iron recovery rate was decreased by 0.25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com