Post-treatment method of homocystine reaction solution

A technology of homocystine and reaction solution, applied in chemical instruments and methods, sulfur trioxide/sulfuric acid, preparation of organic compounds, etc., can solve the problems of incomplete recovery of acid, high cost, complicated dialysis recovery device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Methionine (50.0g, 0.37mol) and hydrobromic acid (180.6g, mass percent concentration 47%, 1.05mol) were stirred and mixed evenly at room temperature, and concentrated sulfuric acid (68.0g, mass percent concentration 98% , 0.68mol) and stirred evenly, then hydrothermal co-reacted at 130°C for 13h to obtain a homocystine reaction solution (300mL);

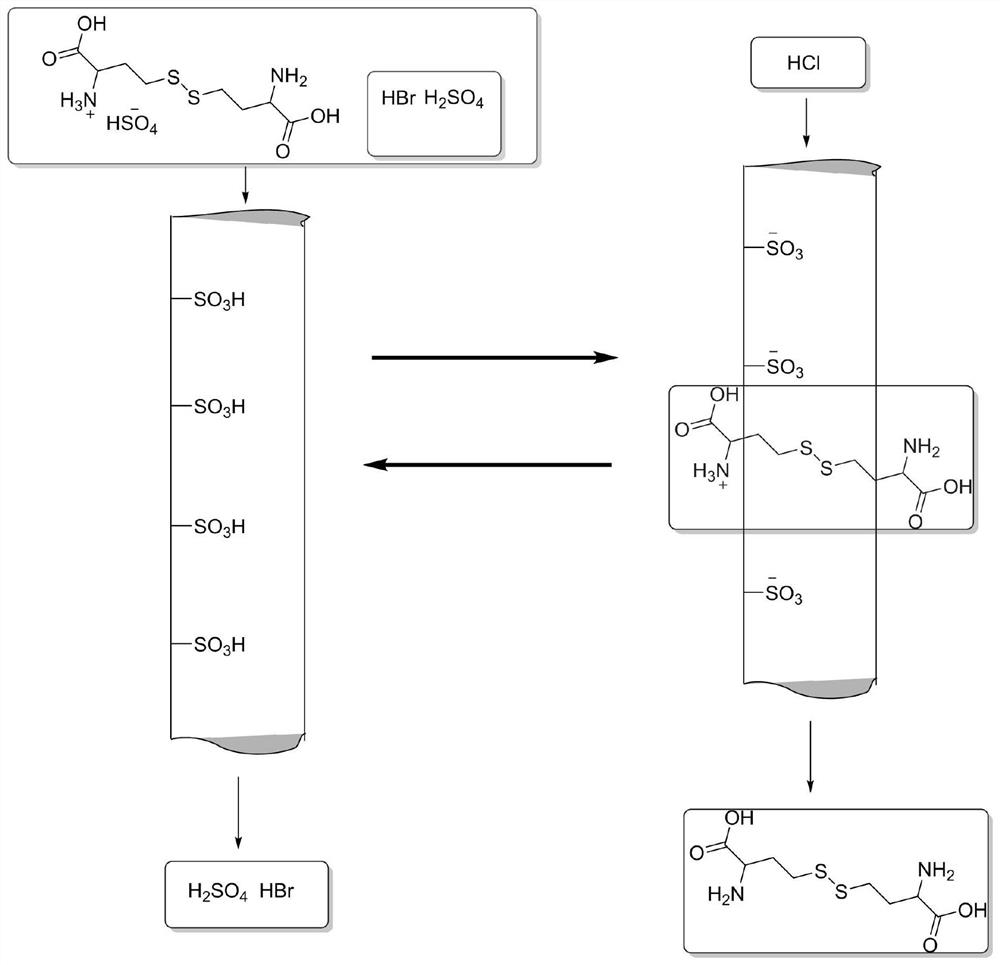

[0052] according to figure 1 The post-treatment method of the homocystine reaction solution shown, after cooling the homocystine reaction solution to room temperature, add 300mL pure water for dilution, and place the gained diluted reaction solution (injection volume is 600mL) in a strong After adsorption in the ion-exchange column of acidic cation exchange resin (model Dowex-50 H type, the resin amount is 500.0g), once eluted with pure water until no sulfuric acid and hydrobromic acid are washed out, water eluent is obtained; water The eluate was recovered after vacuum distillation to obtain mixed acid (hydrochloric acid and...

Embodiment 2

[0056] Methionine (50.0g, 0.37mol) and hydrobromic acid (160.1g, mass percent concentration 47%, 0.93mol) were stirred at room temperature, and concentrated sulfuric acid (80.0g, 0.80mol) was added dropwise and stirred evenly, and then Hydrothermal co-reaction at 125°C for 8 hours to obtain a homocystine reaction solution (about 300 mL);

[0057] After the homocystine reaction solution was cooled to room temperature, 500 mL of pure water was added to dilute it, and the resulting diluted reaction solution (injection volume was 800 mL) was placed in a strongly acidic cation exchange resin (model Amberlite IR-120 H type, resin Amount is 500.0g) after adsorbing in the ion-exchange column, carry out once-elution to ion-exchange column with pure water to no sulfuric acid and hydrobromic acid wash-out, obtain water eluate; Water eluate is after vacuum distillation Recover mixed acid (sulfuric acid and hydrobromic acid solution, mixed acid yield is 97%);

[0058] Utilize 15wt% dilute...

Embodiment 3

[0060] Methionine (50.0g, 0.37mol) and hydrobromic acid (223.8g, mass percent concentration 47%, 1.30mol) were stirred at room temperature, and concentrated sulfuric acid (80.0g, mass percent concentration 98%, 0.80 mol) was stirred evenly, and then hydrothermally co-reacted at 125°C for 8h to obtain a homocystine reaction solution (about 300mL);

[0061] After the homocystine reaction solution is cooled to room temperature, add 500mL of pure water for dilution, and the diluted reaction solution (injection volume: 800mL) is placed in a place filled with a strongly acidic cation exchange resin (model Dowex-650C H type, resin volume 500.0g) after adsorption in the ion-exchange column, the ion-exchange column is eluted once with pure water until no sulfuric acid and hydrobromic acid are washed out to obtain the water eluate; the water eluate is recovered after vacuum distillation Obtain mixed acid (sulfuric acid and hydrobromic acid, mixed acid yield is 97%);

[0062] Use 10wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com