Preparation method and application of myclobutanil molecularly imprinted inverse opal photonic crystal hydrogel sensor

A technology of photonic crystals and molecular imprinting, applied in chemical instruments and methods, analyzing materials through chemical reactions, and analyzing materials through observing the impact on chemical indicators, etc., can solve the problem of myclobutanil fungicide molecules Problems such as imprinting photonic crystal hydrogel to achieve the effect of saving manpower, convenient operation and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The preparation method and application of the myclobutanil molecularly imprinted inverse opal photonic crystal hydrogel film are as follows:

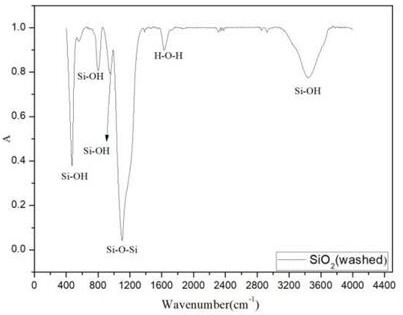

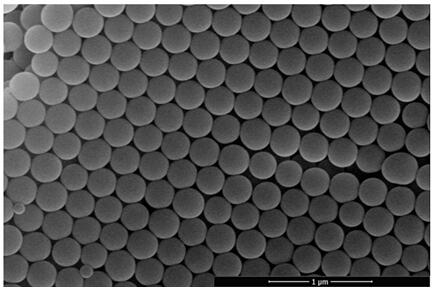

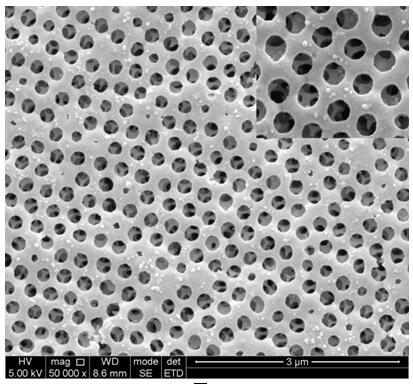

[0031] (1) After preheating the constant temperature water tank to 40°C, fix the two-necked flask above the constant temperature water tank, add ammonia water, ultrapure water and absolute ethanol into the bottle and seal it, set the stirring speed to 1700r / min, and stir fully for 6 minutes Finally, after changing the stirring speed to 400r / min, add the mixture of absolute ethanol and tetraethyl orthosilicate into a two-necked flask and carry out a polymerization reaction at 40°C for 5 hours. After the reaction is completed, centrifuge to remove the supernatant, and wash with absolute ethanol for 2 times, remove the supernatant to obtain SiO 2 Microsphere emulsion; wherein the molar ratio of ammonia water, absolute ethanol and ultrapure water is 1:40:248, and the molar ratio of tetraethyl orthosilicate and absolute eth...

Embodiment 2

[0037] Example 2: The preparation method and application of the myclobutanazole molecularly imprinted inverse opal photonic crystal hydrogel film are as follows:

[0038] (1) After preheating the constant temperature water tank to 35°C, fix the two-necked flask above the constant temperature water tank, add ammonia water, ultrapure water and absolute ethanol into the bottle and seal it, set the stirring speed to 1600r / min, and stir fully for 7 minutes Finally, after changing the stirring speed to 500r / min, add the mixture of absolute ethanol and tetraethyl orthosilicate into a two-necked flask and carry out a polymerization reaction at 35°C for 6 hours. After the reaction is completed, centrifuge to remove the supernatant, and wash with absolute ethanol for 3 times, remove the supernatant to obtain SiO 2 Microsphere emulsion; wherein the mol ratio of ammonia, absolute ethanol and ultrapure water is 1:35:235, and the mol ratio of tetraethyl orthosilicate and absolute ethanol is...

Embodiment 3

[0044] Example 3: The preparation method and application of the myclobutanazole molecularly imprinted inverse opal photonic crystal hydrogel film are as follows:

[0045] (1) After preheating the constant temperature water tank to 30°C, fix the two-necked flask above the constant temperature water tank, add ammonia water, ultrapure water and absolute ethanol into the bottle and seal it, set the stirring speed to 1500r / min, and fully stir for 8 minutes Finally, the stirring speed was changed to 700r / min, and the mixture of absolute ethanol and tetraethyl orthosilicate was added into a two-necked flask for polymerization reaction at 30°C for 7 hours. After the reaction was completed, the supernatant was removed by centrifugation, and washed with absolute ethanol for 2 times, remove the supernatant to get clean SiO 2 Microsphere emulsion; wherein the mol ratio of ammonia, absolute ethanol and ultrapure water is 1:50:250, and the mol ratio of tetraethyl orthosilicate and absolute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com