Graphene multifunctional blended high-elasticity cotton special for bras and preparation method thereof

A multi-functional, graphene technology, applied in applications, rayon manufacturing, textiles and papermaking, etc., can solve the problems of discoloration, short service life, shrinkage, etc., to inhibit easy oxidation yellowing, improve anti-yellowing and oxidation resistance properties, improve dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

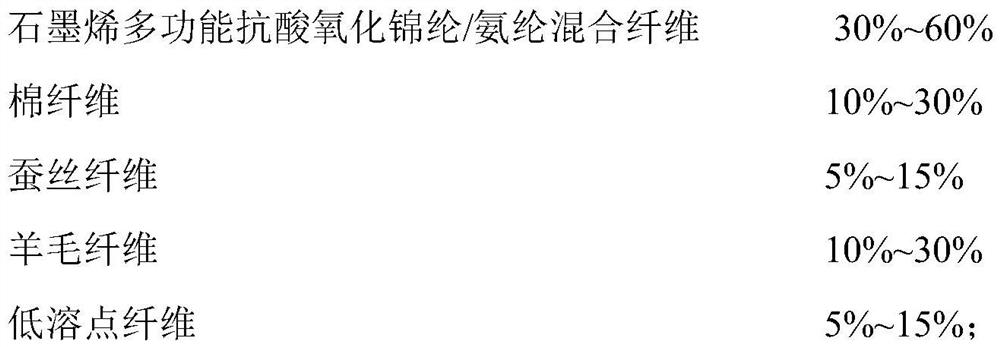

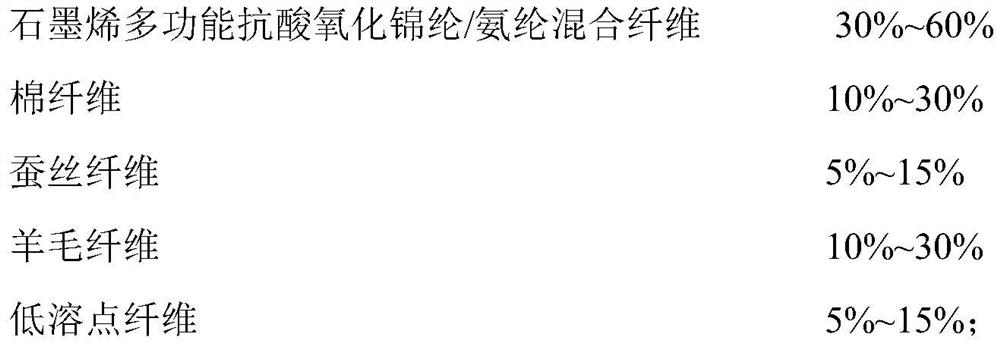

[0031] A kind of graphene multifunctional blended high-elastic bra special cotton of the present embodiment is prepared by the following method:

[0032] (1) Preparation of graphene far-infrared anti-acid oxidation nylon / spandex hybrid fiber:

[0033] 30 parts by weight of far-infrared ceramic powder (ground to a particle size of 50-600 nm by high-energy ball milling before use) and 2 parts by weight of silane coupling agent 3-[3-carboxyacrylamide] propyl triethoxysilane in Humidity is 50%~90% under the air atmosphere, mix uniformly in the high-speed mixer, then add 4 parts by weight of carboxylated graphene (commercially purchased, grind to particle diameter through high-energy ball mill before use and be 50~600nm), 48 parts by weight Nylon fiber chips, 15 parts by weight of spandex fiber chips and 1 part by weight of heat stabilizer pentaerythritol stearate are fully stirred and dispersed evenly, and then the mixture is extruded with a twin-screw extruder to obtain graphene ...

Embodiment 2

[0037] A kind of graphene multifunctional blended high-elastic bra special cotton of the present embodiment is prepared by the following method:

[0038] (1) Preparation of graphene anion anti-acid oxidation nylon / spandex hybrid fiber:

[0039]20 parts by weight of tourmaline anion powder (before use through high-energy ball milling to a particle size of 50-600nm) and 2 parts by weight of silane coupling agent 3-[3-carboxyacrylamide] propyltriethoxysilane in Humidity is 50%~90% under the air atmosphere, mix uniformly in the high-speed mixer, then add 3 parts by weight of carboxylated graphene (commercially purchased, before use, grind to a particle size of 50~600nm through high-energy ball milling), 54 parts by weight Nylon fiber chips, 20 parts by weight of spandex fiber chips and 1 part by weight of heat stabilizer pentaerythritol stearate are fully stirred and dispersed evenly, and then the mixture is extruded with a twin-screw extruder to obtain graphene far-infrared anti-...

Embodiment 3

[0043] A kind of graphene multifunctional blended high-elastic bra special cotton of the present embodiment is prepared by the following method:

[0044] (1) Preparation of graphene antibacterial and acid-resistant oxidized nylon / spandex hybrid fiber:

[0045] 15 parts by weight of antibacterial nano-zinc oxide and nano-titanium dioxide powder (ground to a particle size of 50-600 nm by high-energy ball milling before use) and 1 part by weight of silane coupling agent 3-[3-carboxyallylamide] propyl triethyl Oxysilane is mixed uniformly in a high-speed mixer under an air atmosphere with a humidity of 50% to 90%, and then 2 parts by weight of carboxylated graphene (commercially purchased, ground to a particle size of 50 to 600nm by high-energy ball milling before use) , 61 parts by weight of nylon fiber chips, 20 parts by weight of spandex fiber chips and 1 part by weight of heat stabilizer pentaerythritol stearate are fully stirred and dispersed evenly, and then the mixture is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com