Water-based auxiliary agent for synthetic leather and preparation method thereof

A water-based additive, synthetic leather technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of single function, toughened fibers are not easy to distribute evenly, achieve uniform fluidity and increase tear resistance. , Excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

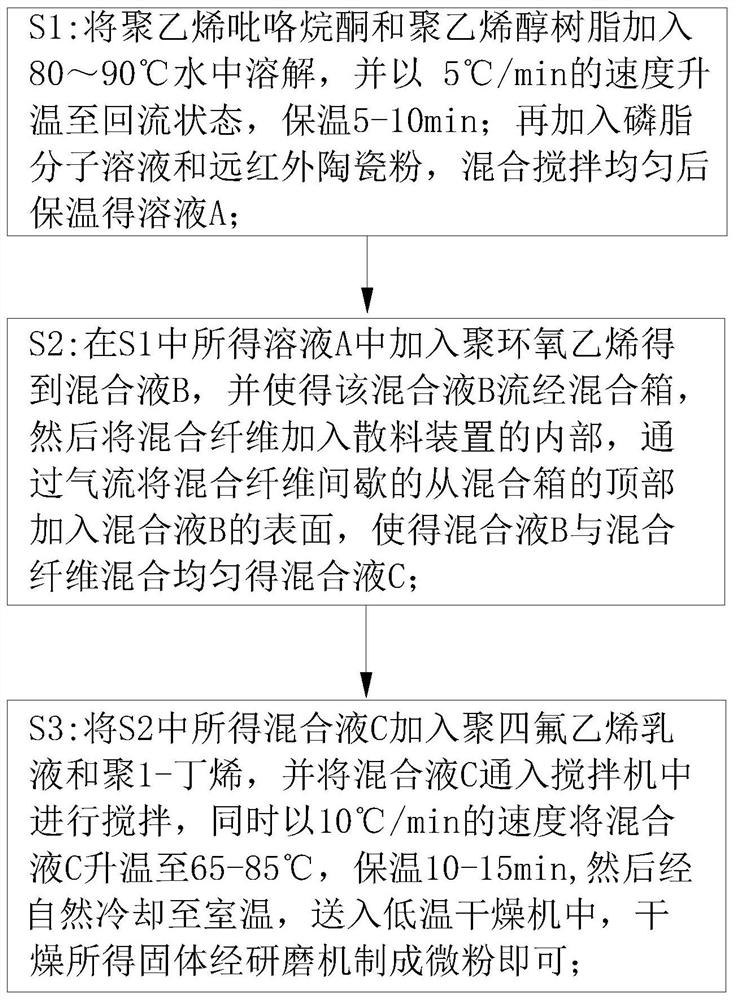

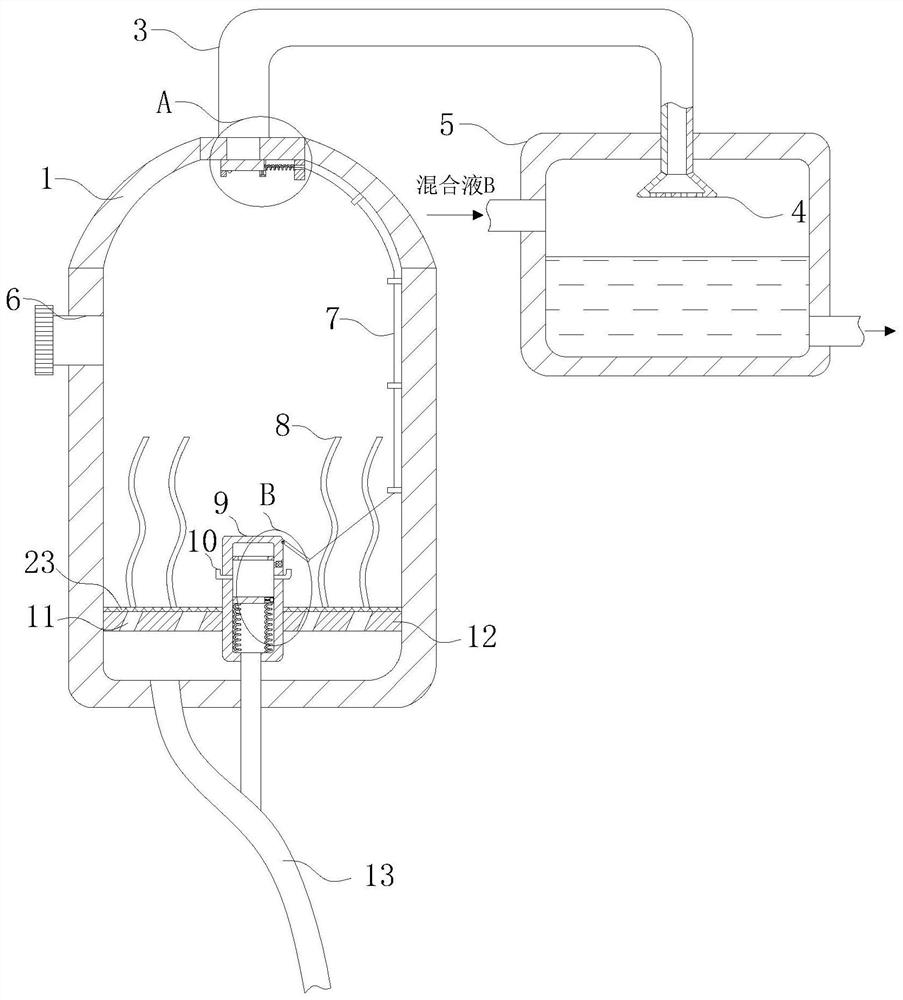

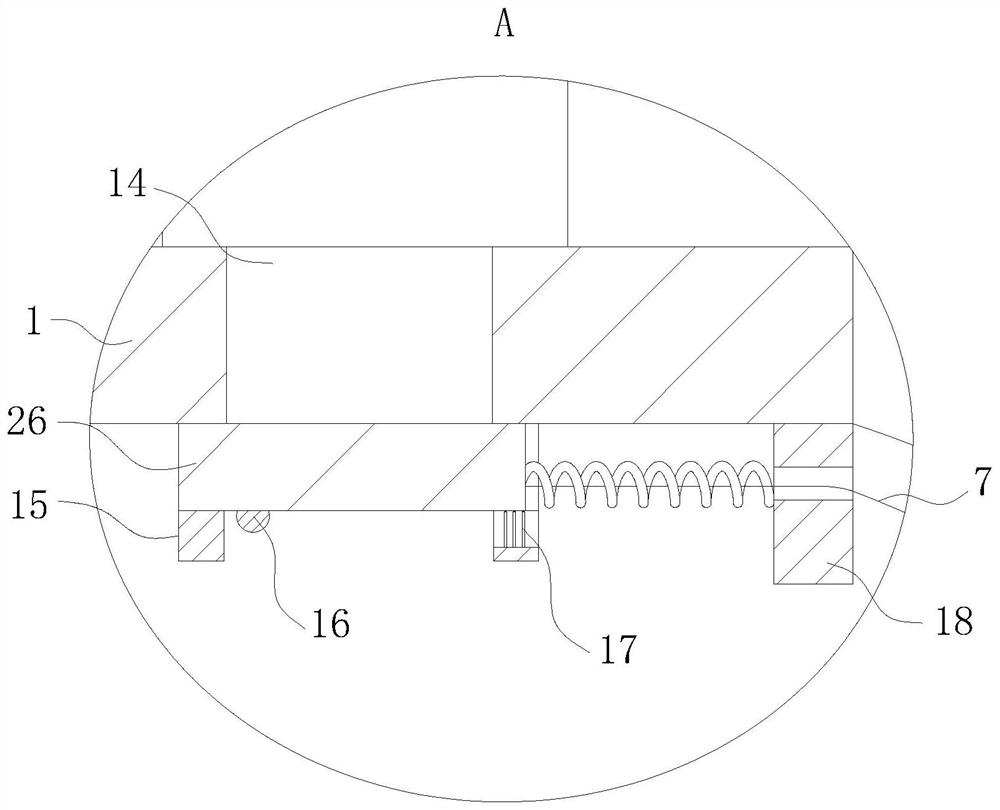

Method used

Image

Examples

Embodiment approach

[0031] As an embodiment of the present invention, the mixed fiber is formed by blending sepiolite fiber and glass fiber; because sepiolite fiber has good wear resistance, and glass fiber has higher strength, but there is For the problem of poor friction resistance, blending the two fibers can obtain a blended fiber with high strength and high wear resistance. When the water-based additive is applied to synthetic leather, it can not only improve the tear resistance of synthetic leather , At the same time, it can improve the wear resistance of synthetic leather.

[0032] As an embodiment of the present invention, the phospholipid molecular solution is formed by mixing and stirring phospholipid powder with water, wherein the specific preparation method of the phospholipid powder is: adding water to crude soybean oil, fully stirring at 70-90° C. for 30 min, The phospholipids are hydrated into colloidal precipitates, and the hydrated phospholipids are obtained by continuous centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com