Extraction method based on magnetic janus particles

An extraction and particle technology, applied in the field of extraction, can solve problems such as the application of magnetic Janus particles that have not been paid attention to, and achieve the effects of increasing the contact area of the two phases, increasing the mass transfer rate, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

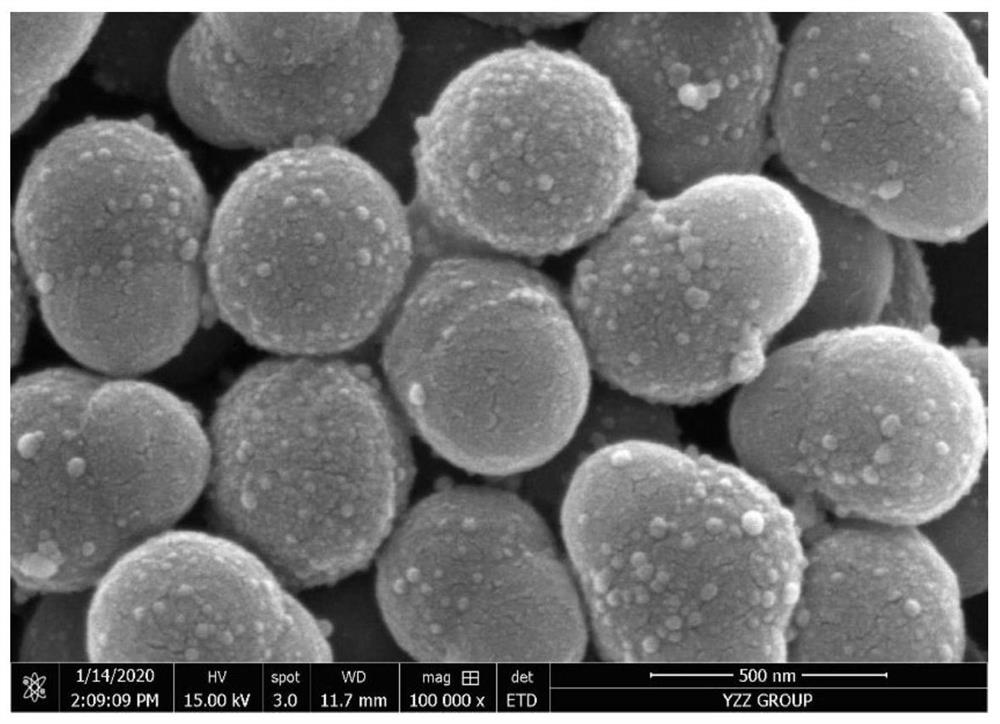

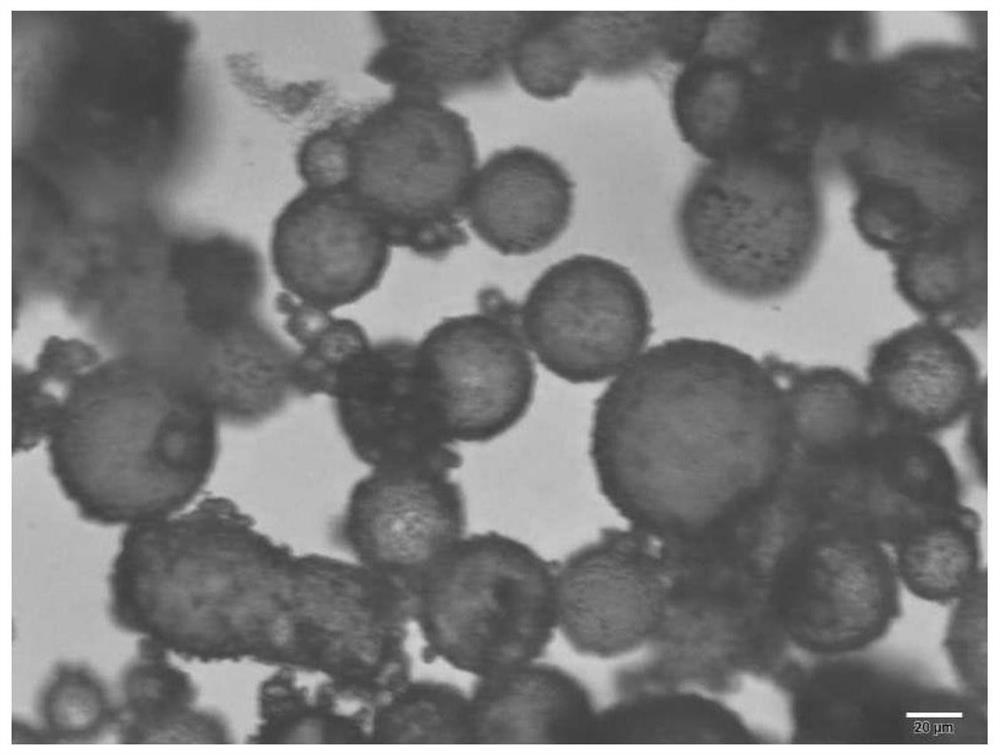

[0093] In 200ml of an aqueous solution of a neodymium compound with a concentration of 100ppm in terms of neodymium, add 4ml of a kerosene solution of 1mol / L monoisooctyl phosphate (P507) and 0.4g (relative to the aqueous solution of neodymium compound and P507 The total amount of kerosene solution, 0.2wt.%) magnetic Janus particles (such as figure 1 The magnetic silica / polystyrene-divinylbenzene Janus particles shown in ) were placed in a shaker at a constant temperature of 25°C and a rotational speed of 130r / min for 20min. After shaking, use a 0.3T magnet to enrich and remove the enriched emulsion part stabilized by the magnetic Janus particles in the system, and the system obtained after separating the enriched emulsion part is allowed to stand for 15 minutes to separate the layers, and then separate the liquid. The residual amount of the neodymium compound in the aqueous phase after the intensive extraction with the magnetic Janus material was 18 ppm in terms of neodymium...

Embodiment 2

[0096] Add 5ml carbon tetrachloride and 0.2g (relative to the total amount of iodine aqueous solution and carbon tetrachloride, 0.2wt.%) magnetic Janus particles (such as figure 1 Magnetic silica / polystyrene-divinylbenzene Janus particles shown in ), placed in a shaker at a constant temperature of 25°C and a rotational speed of 130r / min for 10min. After shaking, use a 0.3T magnet to enrich and remove the enriched emulsion part stabilized by the magnetic Janus particles in the system, and the system obtained after separating the enriched emulsion part is allowed to stand for 15 minutes to separate the layers, and then separate the liquid. The residual amount of iodine in the water phase after the enhanced extraction with the magnetic Janus material is 16 ppm, and the extraction rate of iodine is 84%.

[0097] To the separated enriched emulsion part, an external magnetic field was applied with a 3T magnet, so that the enriched emulsion part was demulsified. Afterwards, a 3T ma...

Embodiment 3

[0099] In 5ml of the kerosene solution of benzoic acid with a volume content of 40%, add 100ml of water and 0.2g (relative to the total amount of the aqueous solution of benzoic acid and water, 0.2wt.%) magnetic Janus particles (such as figure 1 Magnetic silica / polystyrene-divinylbenzene Janus particles shown in ), placed in a shaker at a constant temperature of 25°C and a rotational speed of 130r / min for 10min. After shaking, use a 0.3T magnet to enrich and remove the enriched emulsion part stabilized by the magnetic Janus particles in the system, and the system obtained after separating the enriched emulsion part is allowed to stand for 15 minutes to separate the layers, and then separate the liquid. The residual amount of benzoic acid in the benzoic acid kerosene solution after enhanced extraction by using the magnetic Janus material is 9 ppm, and the extraction rate of benzoic acid is 91%.

[0100] To the separated enriched emulsion part, an external magnetic field was ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com