A large-scale ceramic rock plate and its preparation method

A large-scale, ceramic technology, applied in the field of ceramic tiles, can solve the problems of unable to meet the requirements of large-scale home decoration, dry cracked bricks, many cracked bricks during transportation, and low drying pass rate, so as to improve deep processing performance, green body strength, The effect of reducing stress build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

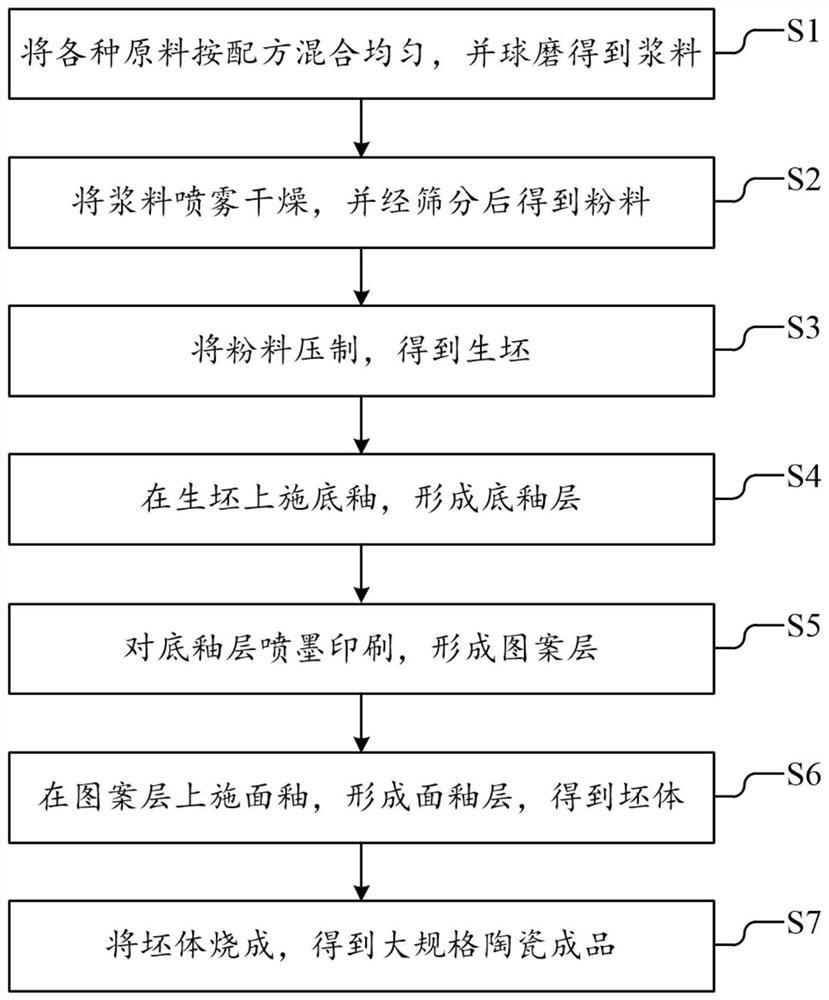

[0057] Correspondingly, refer to figure 2 , the present invention also discloses a method for preparing the above-mentioned large-scale ceramic rock slab, which includes the following steps:

[0058] S1: Mix various raw materials evenly according to the formula, and ball mill to obtain slurry;

[0059] Specifically, the formula is: 15-20 parts of potassium feldspar, 8-15 parts of albite, 15-20 parts of calcined kaolin, 12-20 parts of black mud, 8-15 parts of white mud, 15-20 parts of pyrophyllite, 1-10 parts of the toughening agent; the sum of the parts by weight of the above raw materials is 100 parts. The above formula can be better applied to the existing production line, reduce drying breakage, breakage during transportation and firing breakage, and increase the yield of finished products. At the same time, this formula can also ensure that the deformation is relatively uniform during the drying and firing process, and the passing rate of drying and firing can be improv...

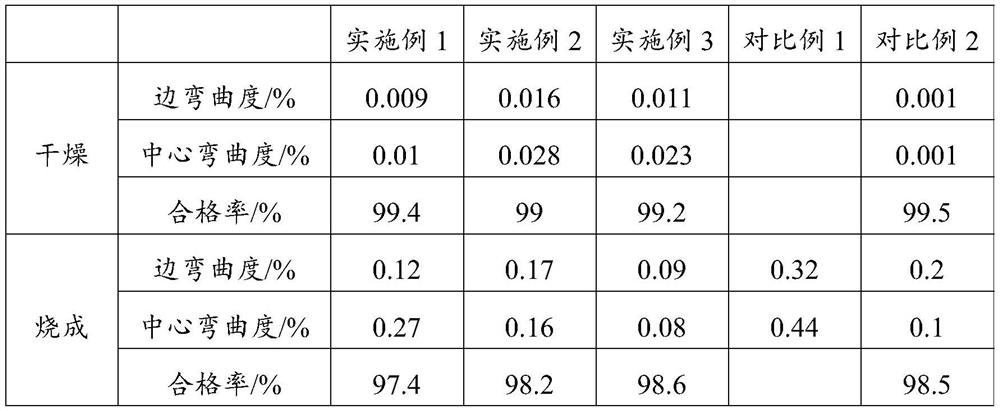

Embodiment 1

[0080] This embodiment provides a large-scale ceramic slab, its size is 3600 × 2000 × 20mm 3 ; Wherein, the thickness of green body layer is 19mm;

[0081] The formula of green body layer is:

[0082] 19 parts of potassium feldspar, 12 parts of albite feldspar, 16 parts of calcined kaolin, 18 parts of black mud, 10 parts of white mud, 18 parts of pyrophyllite, 1 part of low-temperature toughening agent, and 6 parts of high-temperature toughening agent;

[0083] Among them, 80% of the particles in the calcined kaolin have a particle size of less than 1 μm; methyl cellulose is used as the low-temperature toughening agent, and mullite whiskers are used as the high-temperature toughening agent;

[0084] Preparation method of ceramic rock plate:

[0085] (1) Mix various raw materials uniformly according to the formula, and ball mill to obtain slurry;

[0086] Wherein, the 250 mesh sieve of slurry is 0.2%;

[0087] (2) The slurry is spray-dried, and the powder is obtained after ...

Embodiment 2

[0098] This embodiment provides a large-scale ceramic slab, its size is 3600 × 1800 × 25mm 3 ; Wherein, the thickness of green body layer is 24.5mm;

[0099] The formula of green body layer is:

[0100] 19 parts of potassium feldspar, 12 parts of albite feldspar, 16 parts of calcined kaolin, 18 parts of black mud, 10 parts of white mud, 18 parts of pyrophyllite, 1 part of low-temperature toughening agent, and 6 parts of high-temperature toughening agent;

[0101] Among them, 90% of the particles in the calcined kaolin have a particle size of <1 μm; tobermolite is selected as the low-temperature toughening agent, and steatite is selected as the high-temperature toughening agent;

[0102] Preparation method of ceramic rock plate:

[0103] (1) Mix various raw materials uniformly according to the formula, and ball mill to obtain slurry;

[0104]Wherein, the 250 mesh sieve of slurry is 0.4%;

[0105] (2) The slurry is spray-dried, and the powder is obtained after sieving;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com