Anti-corrosion coating for aluminum-magnesium-silicon sagger

An anti-corrosion coating, aluminum-magnesium-silicon technology, applied in the field of anti-corrosion coatings for aluminum-magnesium-silicon saggers, can solve the problems of limited service life of the box body, complicated preparation process, and non-compact structure, and achieve excellent resistance to lithium erosion Chemical composition and organizational structure, simple preparation process, and the effect of inhibiting penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

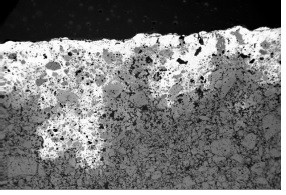

Image

Examples

Embodiment 1

[0017] Sagger anti-corrosion coating solid component and mass percentage: CaCO 3 , 60.4%, TiO 2 , 20%; SiO 2 , 2%; Al 2 o 3 , 10%; Borax, 2.5%; FS10, 0.1%; Calcium aluminate cement, 5%. First premix the above solid powder in a vibrating ball mill tank, then add the mixed mixture into a planetary ball mill tank, and then add 40% water of the total weight of the above raw materials for wet mixing. The mixing time is 120 minutes, and the obtained slurry It is the coating of the present invention, and the construction method can be applied to the inner wall of the aluminum-magnesium-silicon green body sagger by brushing, spraying, dipping, etc., and the firing temperature ranges from 1200 to 1300.

Embodiment 2

[0019] Sagger anti-corrosion coating solid components and mass percentages are: MgCl 2 , 38.7%, TiO 2 , 40%; SiO 2 , 10%; Al 2 o 3 , 5%; Borax, 1%; FS20, 0.3%; Aluminum sol solution, 9%. First premix the above solid powder in a vibrating ball mill tank, then add the mixed mixture into a planetary ball mill tank, and then add 10% water of the total weight of the above raw materials for wet mixing. The mixing time is 240min, and the obtained slurry It is the coating of the present invention, and the construction method can be applied to the inner wall of the aluminum-magnesium-silicon green body sagger by brushing, spraying, dipping, etc., and the firing temperature range is 1250-1350.

Embodiment 3

[0021] Sagger anti-corrosion coating solid component and mass percentage are: BaSO 4 , 70%, TiO 2 , 20.2%; SiO 2 , 2.2%; Al 2 o 3 , 5.3%; Borax, 1.3%; T85, 0.2%; Carboxymethylcellulose, 0.3%. First premix the above solid powder in a vibrating ball mill tank, then add the mixed mixture into a planetary ball mill tank, and then add 30% water of the total weight of the above raw materials for wet mixing. The mixing time is 60 minutes, and the obtained slurry It is the coating of the present invention. The construction method can be applied to the inner wall of the aluminum-magnesium-silicon cooked sagger by brushing, spraying, dipping, etc., and the firing temperature ranges from 1300 to 1400.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com