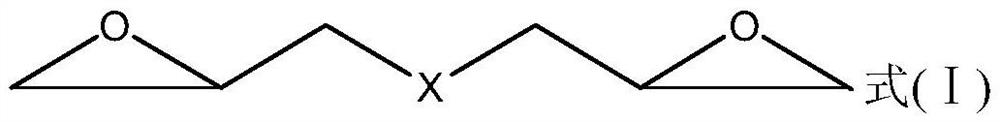

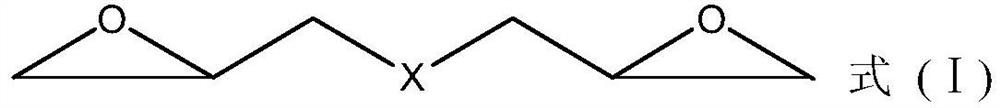

Preparation method of epoxy compound

A technology for epoxy compounds and hydrogen sulfide, which is applied in chemical instruments and methods, chemical/physical processes, organic compounds/hydrides/coordination complex catalysts, etc. and other problems, to achieve the effect of less investment in equipment, low cost of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

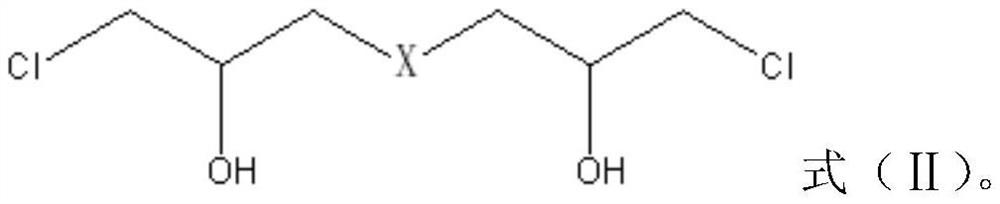

[0035] A kind of preparation method of episulfide compound, its specific method is:

[0036] 1) Add 56.1g of quaternary ammonium strong base anion exchange resin catalyst, 561g of methanol, and 187g of epichlorohydrin into a 1000mL four-neck bottle, stir, cool down to 5°C, and then feed 1.05 moles of hydrogen sulfide gas into the mixed solution, and feed the gas The speed was 1.0L / h, and reacted for 3 hours after passing through the hydrogen sulfide. At this time, there was no raw material left, and it was filtered. The filtrate was distilled off the solvent under reduced pressure, and the intermediate A was obtained after spin-drying methanol. The content was 98.95%, and the yield 99.23%; catalyst resin and solvent can continue to be used as the next batch of reactions;

[0037] 2) Add 549.29g of guanidine-based resin catalyst, 549.29g of tetrahydrofuran, and 219.72g of intermediate A into a 1000mL four-neck flask, heat up to 40°C, and react for two hours. When the mass fract...

Embodiment 2

[0039] A kind of preparation method of episulfide compound, its specific method is:

[0040] 1) In a 1000mL four-necked bottle, add quaternary ammonium strong base anion exchange resin catalyst (this catalyst is the seventh time application of the quaternary ammonium strong base anion exchange resin in Example 1) 56.1g, methanol 561g, epichlorohydrin 187g, stir, cool to 2 ℃, then feed 1.05 moles of hydrogen sulfide gas into the reaction solution, the speed of feeding the gas is 2.2L / h, and react for 3.5 hours after the hydrogen sulfide is passed through. Solvent, obtain intermediate A after spin-drying methanol, its content is 96.52%, yield 98.13%; Catalyst resin and solvent can continue to be used as next batch of reaction;

[0041] 2) In a 1000mL four-necked bottle, add guanidine-based resin catalyst (this catalyst is the third application of guanidine-based resin in Example 1) 556.63g, ethylene glycol phenyl ether 556.63g, intermediate A 222.65g, and heat up to 60 DEG C, r...

Embodiment 3

[0043] A kind of preparation method of episulfide compound, its specific method is:

[0044]1) Add 56.1g of quaternary ammonium strong base anion exchange resin catalyst, 561g of methanol, and 187g of epichlorohydrin into a 1000mL four-necked bottle, stir, heat up to 8°C, then feed 1.05 moles of hydrogen sulfide gas into the reaction solution, and feed the The speed was 5L / h, and reacted for 4 hours after the hydrogen sulfide was passed through. At this time, there was no raw material left, and it was filtered. The filtrate was distilled off the solvent under reduced pressure, and the intermediate A was obtained after spin-drying methanol. %; Catalyst resin and solvent can continue to be used as next batch of reaction simultaneously;

[0045] 2) Add 548.28g of guanidinium resin catalyst, 548.28g of ethylene glycol phenyl ether, and 219.31g of intermediate A into a 1000mL four-neck flask, heat up to 60°C, and react for 3 hours, and react when the mass fraction of intermediate A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com