Preparation method of formaldehyde-free textile color fixing agent

A textile and color-fixing agent technology, applied in the field of preparation of formaldehyde-free textile color-fixing agent, can solve problems such as ulcers and skin inflammation, achieve good color fixing, improve water resistance, and improve dry/wet rubbing fastness performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

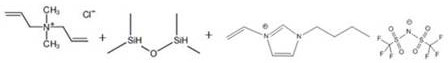

Image

Examples

Embodiment 1

[0026] A kind of preparation method of formaldehyde-free textile color fixing agent, its main scheme is as follows:

[0027] Add 80g of polyether diol and 35g of isophorone diisocyanate into the reaction kettle, control the temperature to 75°C under the protection of nitrogen, then add 0.01g of catalyst, keep the reaction for 1h, and then add 3.8g of bismethylol Propionic acid is dissolved in 40g of N-methylpyrrolidone, and added to the reactor, and the heat preservation reaction is continued for 45min, then 5.2g of chain extender is added, and the reaction is performed for 20min; after completion, 18g of ionic liquid modified silane is added to control Warm at 55°C and react for 40 minutes; after completion, cool down to 40°C, add 4.8g of triethylamine, keep warm for 30 minutes, add 500g of deionized water after completion, stir rapidly for 3-6h, and filter to obtain the above-mentioned free Aldehyde textile color fixing agent.

[0028] A kind of ionic liquid modified silane...

Embodiment 2

[0035] A method for preparing a formaldehyde-free textile color-fixing agent, the main scheme of which is as follows:

[0036] Add 120g of polyether diol and 50g of isophorone diisocyanate into the reaction kettle, control the temperature to 78°C under the protection of nitrogen, then add 0.09g of catalyst, keep the temperature for 2 hours, and then add 5.6g of bismethylol Propionic acid was dissolved in 50g of N-methylpyrrolidone, and added to the reaction kettle, and the heat preservation reaction was continued for 85min, and then 6.9g of chain extender was added and reacted for 40min; after completion, 22g of ionic liquid modified silane was added to control Temperature at 58°C, react for 60 minutes; after completion, cool down to 50°C, add 6.2g of triethylamine, keep warm for 35 minutes, add 560g of deionized water after completion, stir rapidly for 5 hours, and filter to obtain the formaldehyde-free textile Fixative.

[0037] A kind of ionic liquid modified silane is pre...

Embodiment 3

[0044] Add 160g of polyether diol and 60g of isophorone diisocyanate into the reaction kettle, control the temperature to 90°C under the protection of nitrogen, then add 0.5g of catalyst, keep the reaction for 4h, and then add 10.6g of bismethylol Propionic acid was dissolved in 80g of N-methylpyrrolidone, and added to the reaction kettle, and the heat preservation reaction was continued for 120min, and then 8.8g of chain extender was added and reacted for 60min; after completion, 26g of ionic liquid modified silane was added to control Temperature at 75°C, react for 90 minutes; after completion, cool down to 60°C, add 8.6g of triethylamine, keep warm for 45 minutes, add 600g of deionized water after completion, stir rapidly for 6 hours, and filter to obtain the formaldehyde-free textile Fixative.

[0045] A kind of ionic liquid modified silane is prepared according to the following method: 80g of dimethyl diallyl ammonium chloride; 30g of 1,1,3,3-tetramethyldisiloxane; 0.9g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com