Method for enhancing biofilm culturing performance of graphene oxide modified biological filler

A technology of biological fillers and oxide stones, applied in the direction of coating, etc., can solve the problems of reducing the service life of fillers, difficult to effectively combine the interface, complicated operation, etc., to enhance the bonding strength of the interface, increase the slow speed of film formation, and increase the surface energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

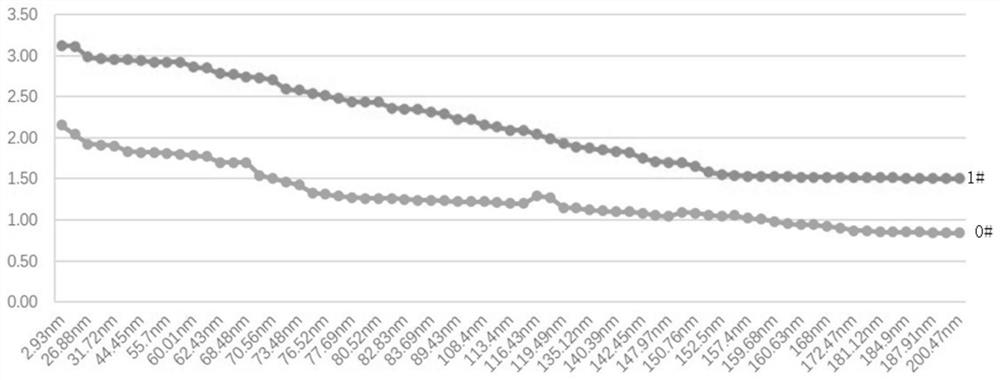

Embodiment 1

[0028] This embodiment relates to a method for enhancing the film-hanging performance of graphene oxide modified biofillers, said method comprising the steps of:

[0029] Step 1, dissolving the silane coupling agent (3-aminopropyl-triethoxy silicon) in 95 wt% aqueous ethanol to prepare an aqueous ethanol solution of the silane coupling agent with a mass concentration of 8 g / L;

[0030] Step 2, at room temperature, immerse the pre-cleaned polyethylene filler substrate in the prepared ethanol solution of silane coupling agent for 2 hours, then take it out and dry it at 110°C for 2 hours, take it out and dry it for storage spare;

[0031] Step 3, weighing a certain amount of graphene oxide powder, dispersing it in deionized water under stirring, and ultrasonicating for 4 hours to obtain a 0.5g / L uniform dispersion;

[0032] Step 4, place the treated filler substrate in the above graphene oxide dispersion, immerse for 4 hours under pressure, and dry at 80°C for 2 hours, graphene ...

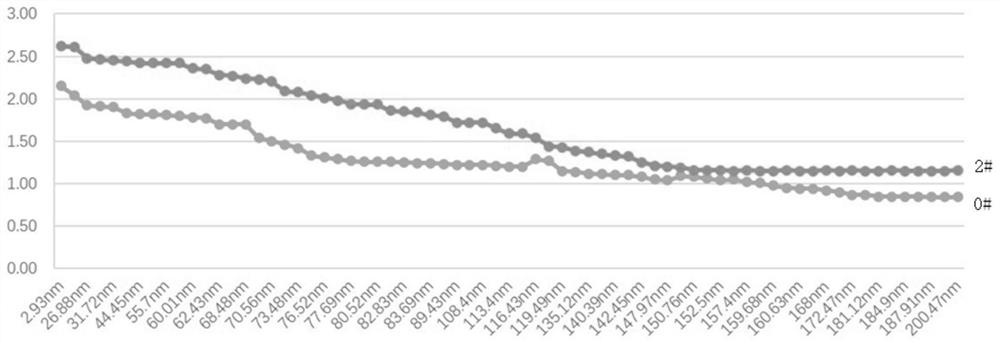

Embodiment 2

[0035] This embodiment relates to a method for enhancing the film-hanging performance of graphene oxide modified biofillers, said method comprising the steps of:

[0036] Step 1, dissolving the silane coupling agent (3-aminopropyl-triethoxy silicon) in 95 wt% ethanol aqueous solution to prepare an ethanol aqueous solution with a mass concentration of 2 g / L of the silane coupling agent;

[0037] Step 2, at room temperature, immerse the pre-cleaned polyethylene filler substrate in the prepared ethanol solution of silane coupling agent for 2 hours, then take it out and dry it at 110°C for 2 hours, take it out and dry it for storage spare;

[0038] Step 3, weighing a certain amount of graphene oxide powder, dispersing it in deionized water under stirring, and ultrasonicating for 4 hours to obtain a 0.5g / L uniform dispersion;

[0039] Step 4, place the treated filler substrate in the above-mentioned graphene oxide dispersion liquid, impregnate for 4 hours under pressure driving, a...

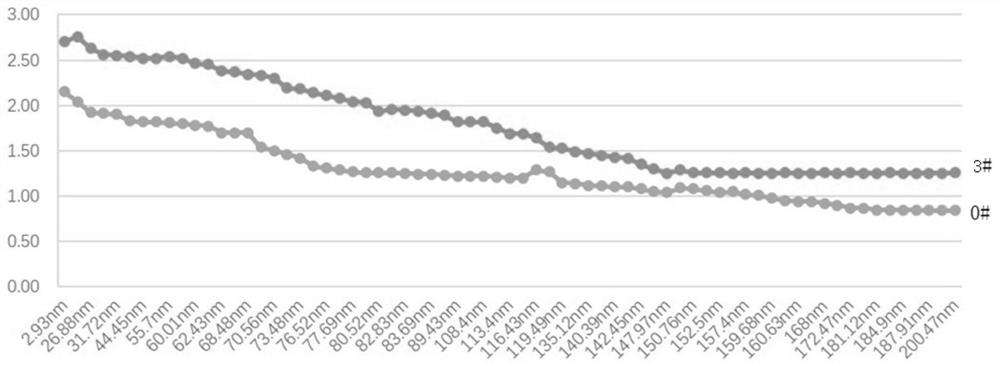

Embodiment 3

[0042] This embodiment relates to a method for enhancing the film-hanging performance of graphene oxide modified biofillers, said method comprising the steps of:

[0043] Step 1, dissolving the silane coupling agent (3-aminopropyl-triethoxy silicon) in 95 wt% aqueous ethanol to prepare an aqueous ethanol solution of the silane coupling agent with a mass concentration of 8 g / L;

[0044] Step 2, at room temperature, immerse the pre-cleaned polyethylene filler substrate in the prepared ethanol solution of silane coupling agent for 2 hours, then take it out and dry it at 80°C for 2 hours, then take it out and dry it for storage spare;

[0045] Step 3, weighing a certain amount of graphene oxide powder, dispersing it in deionized water under stirring, and ultrasonicating for 4 hours to obtain a 0.5g / L uniform dispersion;

[0046] Step 4, place the treated filler substrate in the above graphene oxide dispersion, immerse for 8 hours under pressure, and dry at 80°C for 2 hours, graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com