Separator-less conductive polymer solid electrolyte secondary battery

A technology of solid electrolyte and conductive polymer, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, solid electrolytes, etc., can solve the problems of excessive load process and mass production problems, and achieve small temperature dependence and safety Excellent, redox resistance stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Conductive polymer solid electrolyte: garnet-based material + polymer conductive composition {grafted polymer (X 1 )+ molten salt (LiFSI) (X 2 )+support salt}

[0139] Cathode: LiCoO 2 + Conductive material {nanoparticle carbon ("SUPERC65" manufactured by IMERYS Graphite & Carbon Co., Ltd.)}

[0140] Negative electrode: natural spherical graphite + conductive material ("SUPER P-Li" manufactured by the same company)

[0141] The preparation method of conductive polymer electrolyte membrane:

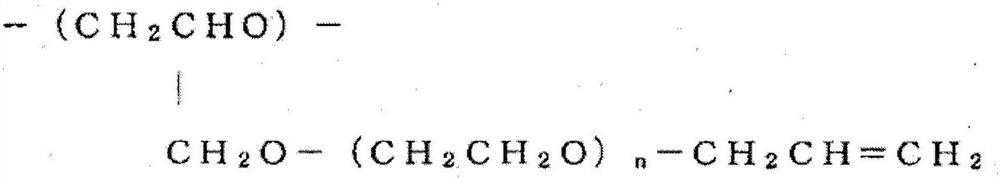

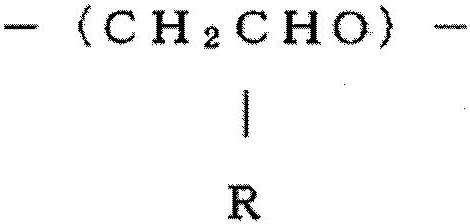

[0142] Conductive polymer solid electrolyte: Inorganic solid electrolyte Li 7 La 3 Zr 2 o 12 [Classification number "LLZO-PT" of our company (Piotrek)] (90% by weight), and a polymer conductive composition {vinylidene fluoride copolymer (manufactured by Kureha Chemical Industry Co., Ltd. "KUREHA-K75";-( CH 2 -CF 2 ) m -(CF 2 -CFCl) n (m=96 mol%, n=4 mol%)} grafted 70 mol% molten salt monomer (ionic liquid) {2-(methacryloyloxy)ethyltrimethylammonium bis(fluorosulfonyl )...

Embodiment 2

[0146]Conductive polymer solid electrolyte: use garnet-based materials (80% by weight), and a polymer conductive composition {in making molten salt monomer (ionic liquid) MOETMA-FSI 50 mol% and polyvinylidene fluoride manufactured by Solvay Company Vinyl resin "Solvay#5130" (polyvinylidene fluoride polymer) graft polymerized (X 1 ), fit relative to (X 1 ) is 30% by weight of LiFSI as a supporting salt (20% by weight)}.

[0147] Cathode: LiCo 13 Ni 13 mn 13 o 2 + Conductive material {nanoparticle carbon (SUPER C65)}

[0148] The surface of the positive electrode is impregnated with (X 1 ) in which 30% by weight of LiTFSI as a supporting salt was blended with respect to the conductive polymer composition.

[0149] Positive method:

[0150] In the polymer conductive composition [make molten salt monomer (ionic liquid) {2-(methacryloyloxy)ethyltrimethylammonium (MOETMA) bis(fluorosulfonyl)imide (MOETMA-FSI)} 50% by mole of graft-polymerized vinylidene fluoride copolymer (...

Embodiment 3

[0160] Conductive polymer solid electrolyte: use garnet-based material (LAGP) (80% by weight), and a polymer conductive composition {make molten salt monomer MOETMA-FSI 60 mol% and ARK EMA company polyvinylidene fluoride Resin "Kyner HSV1800" (polyvinylidene fluoride polymer) graft polymerized material (X 1 ) and molten salt monomer (MOETMA-FSI) homopolymer (X 3 ) of the total amount} (20% by weight). (X 1 ): (X 3 ) is 90:10 by weight ratio.

[0161] Cathode: LiCoO 2 + Conductive material {nanoparticle carbon (SUPER P-Li)}

[0162] Negative electrode: lithium metal foil

[0163] Positive method:

[0164] Using the above LiCoO 2 The positive pole is used as the positive pole. By weight ratio (X 1 ): (X 3 ) into 90:10 with the above polymer conductive composition (X 1 ) and molten salt monomer homopolymer (X 3 ), doped with supporting salt (LiBF 4 )30% by weight to obtain polymer conductive composition (X 3 ), was further diluted with an acetonitrile solvent to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com