High-elastic barrier foam and preparation method thereof

A foam and high-elastic technology, applied in the field of high-elastic barrier foam and its preparation, can solve the problem of poor tensile strength, elongation at break, poor tear strength, and the inability of foam to effectively block water, fire or radiation , The scope of application of the product is limited, etc., to achieve the effect of improving the tensile strength and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

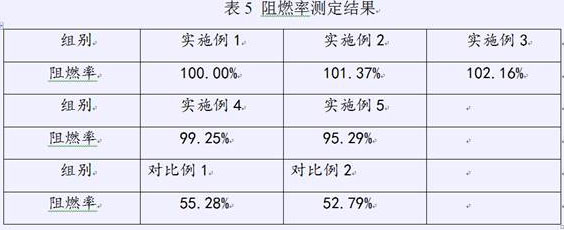

Examples

preparation example Construction

[0032] In order to prepare the above-mentioned high elastic barrier foam, the present invention also provides a preparation method, the preparation method comprising the following steps:

[0033] S1: 85-95 parts of polyether polyol, 20-35 parts of diphenylmethane diisocyanate, 1-2 parts of foaming agent, 0.2-0.7 parts of catalyst, 3-5 parts of flame retardant, 3-5 parts of waterproofing agent 1-6 parts and 1-6 parts of silicone oil, wherein, the polyether polyol with a hydroxyl value of 75-135 is mixed and foamed to prepare the base layer; wherein, the temperature for mixing and foaming the materials is 80-90°C, and the reaction time is 5~20min.

[0034] S2: 30-45 parts of EVA, 4-6 parts of talc powder, 6-8 parts of lime powder, 10-20 parts of triethyl phosphate, 32-42 parts of epoxy modified silicone resin powder, 10- 12 parts and 0.3-1 parts of sodium polycarboxylate dispersant are mixed and foamed to prepare a barrier layer;

[0035] S3: 90-95 parts of polyurethane and 5-...

Embodiment 1

[0040] The high-elastic barrier foam provided in Example 1 of the present invention includes a base layer, a barrier layer, and a reinforcement layer that are sequentially thermally fused together; wherein, the base layer includes by weight: 90 parts of polyether polyol, diphenyl 28 parts of methane diisocyanate, 2 parts of foaming agent, 0.5 part of catalyst, 4 parts of flame retardant, 4 parts of waterproofing agent and 3 parts of silicone oil, wherein the hydroxyl value of the polyether polyol is 90; Parts by weight include: 40 parts of EVA, 5 parts of talcum powder, 7 parts of lime powder, 15 parts of triethyl phosphate, 37 parts of epoxy-modified silicone resin powder, 11 parts of styrene-acrylic emulsion, 0.6 parts of sodium polycarboxylate dispersant parts; the reinforcing layer includes by weight parts: 92 parts of polyurethane, 7 parts of magnesium hydroxide. The flame retardant is a brominated flame retardant, and the catalyst is stannous octoate.

[0041] The high ...

Embodiment 2

[0048] The high-elastic barrier foam provided in Example 2 of the present invention includes a base layer, a barrier layer, and a reinforcing layer that are thermally fused in sequence; wherein, the base layer includes by weight: 85 parts of polyether polyol, diphenyl 35 parts of methane diisocyanate, 2 parts of foaming agent, 0.2 part of catalyst, 3 parts of flame retardant, 3 parts of waterproofing agent and 6 parts of silicone oil, wherein the hydroxyl value of the polyether polyol is 100; Parts by weight include: 30 parts of EVA, 4 parts of talcum powder, 6 parts of lime powder, 10 parts of triethyl phosphate, 32 parts of epoxy-modified silicone resin powder, 10 parts of styrene-acrylic emulsion, 0.3 parts of sodium polycarboxylate dispersant parts; the reinforcing layer includes by weight parts: 92 parts of polyurethane, 8 parts of magnesium hydroxide. The flame retardant is brominated flame retardant, and the catalyst is stannous isooctanoate.

[0049] The high elastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com