Novel thermal-insulation fireproof anticorrosion waterproof composite material

A composite material and profile technology, which is applied in the field of new thermal insulation, fireproof, anti-corrosion and waterproof composite materials, can solve the problems of insufficiently protruding foam glass, complicated process steps, etc., and achieves simple processing, increased structural stability, and simplified construction technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

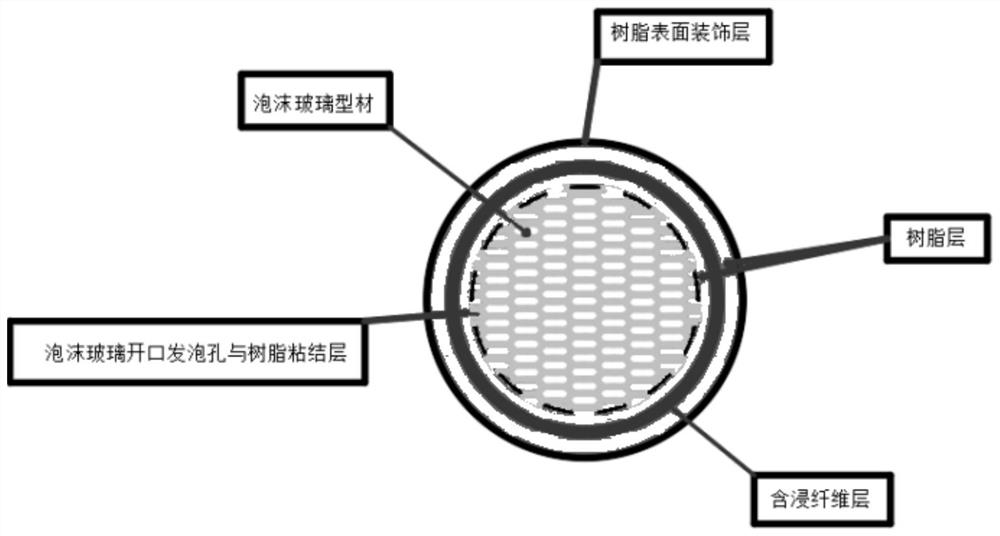

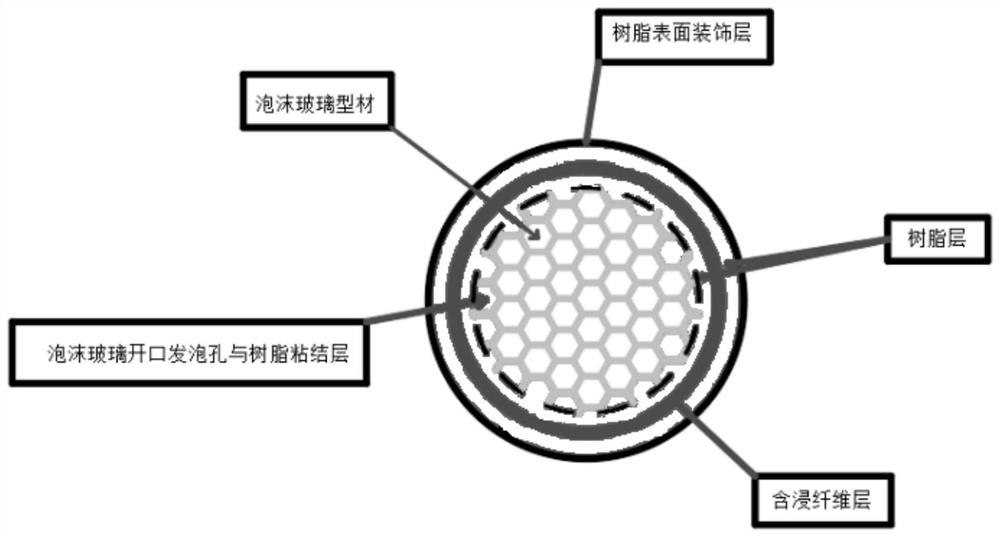

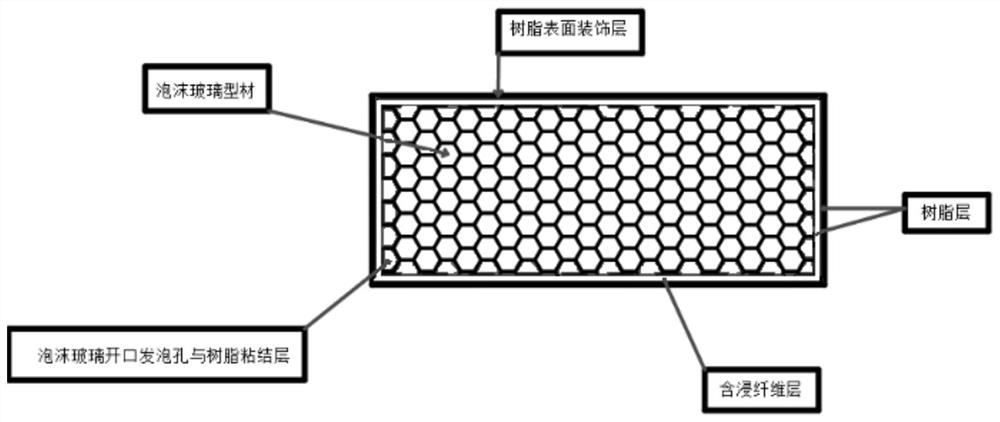

[0031] A novel temperature-insulating, fire-proof, anti-corrosion, and waterproof composite material, comprising a foam glass profile layer and a resin layer, the resin layer is located around the foam glass profile layer, and is in the foaming holes opened on the surface of the foam glass and in the through hole in the middle of the profile layer It is impregnated with resin, so as to be integrated with the foam glass profile, and the entire composite profile has integrity and pressure support, connection and fixation performance, and there is a surface treatment fireproof layer on the surface of the resin layer, which includes but not limited to paint, resin sheet film, metal Plates, inorganic plates, etc.

[0032] The foam glass profile is an inorganic non-metallic glass made of cullet, foaming agent, modifying additive and foaming accelerator, finely pulverized and uniformly mixed, then melted at high temperature, foamed and annealed The material is made of rigid cellular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com